Weldable plastic sheets have become a cornerstone of modern manufacturing, offering unparalleled versatility and durability across industries like construction, automotive, and industrial fabrication.

This article aims to unveil the secrets of weldable plastic sheets, exploring their properties, applications, and the innovative techniques that unlock their full potential.

What Are Weldable Plastic Sheets?

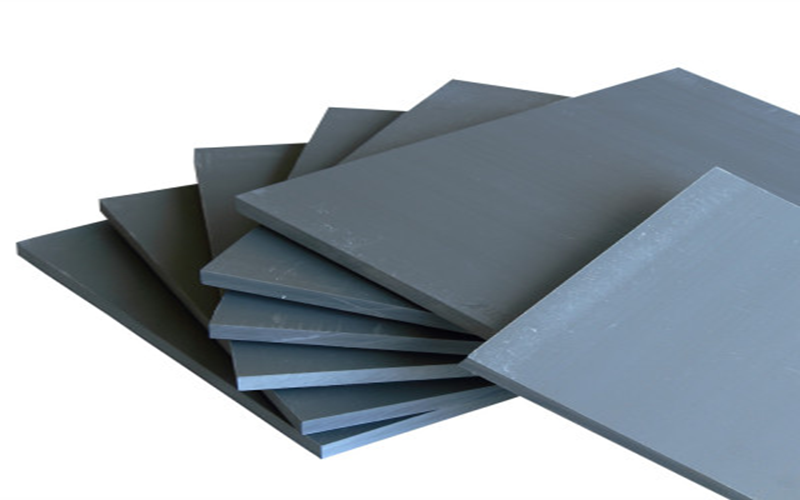

Weldable plastic sheets are specialized thermoplastic materials designed to be easily joined together using various welding techniques, such as butt welding and hot air welding.

The ability to weld these sheets allows manufacturers to create large, seamless structures with excellent structural integrity and load-bearing capacity.

Additionally, these sheets can be precisely fabricated through CNC machining and bending processes to meet specific design requirements, making them highly versatile for custom applications.

Their recyclability and eco-friendly characteristics further enhance their appeal in sustainable manufacturing and industrial markets.

Types Of Weldable Plastic Sheets

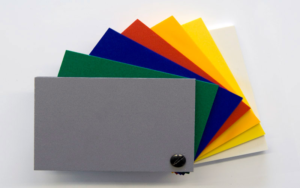

Each type of weldable plastic sheet comes in various thicknesses and colors, allowing customization based on the specific needs of customers and applications.

Understanding these types helps in selecting the right material to optimize performance, fabrication ease, and durability.

High Density Polyethylene (HDPE) Sheet

High Density Polyethylene sheet is a widely used weldable plastic sheet known for its exceptional combination of strength, chemical resistance, and durability.

HDPE’s ability to maintain performance across a wide temperature range from low temperatures without becoming brittle to elevated temperatures without deforming makes it an ideal material for demanding fabrication projects.

Additionally, HDPE sheets are recyclable and can be reused, contributing to resource efficiency and sustainability in manufacturing.

Their machinability also allows for precise CNC milling and shaping, making HDPE a preferred choice for custom applications that require both strength and flexibility.

Acrylonitrile Butadiene Styrene (ABS) Sheet

Acrylonitrile Butadiene Styrene sheet is a highly durable and rigid thermoplastic known for its excellent impact resistance and dimensional stability.

The material’s ability to be precisely cut, bent, and welded using techniques like butt welding and hot air welding further increases its versatility.

ABS sheets are available in a variety of thicknesses and colors, allowing manufacturers to select the best form and stock for their specific fabrication needs.

Polypropylene (PP) Sheet

Polypropylene sheet is a versatile weldable plastic sheet known for its lightweight nature and excellent chemical resistance, making it highly suitable for industrial applications where exposure to corrosive substances is common.

Additionally, polypropylene can be easily fabricated using methods such as butt welding and hot air welding, ensuring strong, seamless joints.

The combination of these properties makes polypropylene an efficient, cost-effective material choice for manufacturers seeking durable and reliable weldable plastic sheets.

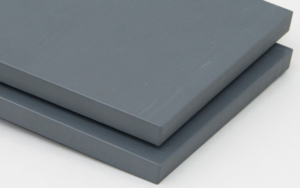

Polyvinyl Chloride (PVC) Sheet

Polyvinyl Chloride sheet is a highly versatile and widely used weldable plastic sheet known for its excellent chemical resistance and good weldability.

Additionally, PVC weldable plastic sheets maintain their structural integrity across a wide temperature range, contributing to their popularity in both indoor and outdoor applications.

Their compatibility with common welding techniques such as butt welding and hot air welding allows for strong, seamless joints, enhancing the overall strength and functionality of fabricated products.

Polycarbonate (PC) Sheet

Polycarbonate sheet is a highly durable and transparent weldable plastic sheet known for its exceptional impact resistance and clarity.

Additionally, polycarbonate sheets maintain their mechanical properties over a wide temperature range, ensuring reliable performance in diverse environments.

This combination of features positions polycarbonate as a premium weldable plastic sheet for projects requiring both durability and visual clarity.

Acrylic Sheet

Acrylic sheets are a popular type of weldable plastic sheet known for their excellent clarity, weather resistance, and ease of fabrication.

These sheets offer a lightweight yet durable alternative to glass, making them ideal for applications requiring transparency and impact resistance, such as signage, displays, and protective barriers.

Acrylic sheets can be welded using hot air welding techniques, which soften the edges to create strong, seamless joints without compromising their optical properties.

Characteristic Of Weldable Plastic Sheet

The utility and performance of weldable plastic sheets are enhanced by a range of engineered characteristics.

High Impact Strength

Weldable plastic sheets, particularly those made from HDPE and ABS, are renowned for their high impact strength, making them ideal for applications that demand robust and durable materials.

This exceptional impact resistance enables these plastics to absorb and withstand significant forces without cracking, deforming, or compromising structural integrity.

Their molecular structure and toughness contribute to maintaining performance under heavy loads and harsh conditions, ensuring long-term reliability.

Durability

Durability is a key attribute of weldable plastic sheets, making them highly sought after in demanding industrial and commercial applications.

These sheets are engineered to withstand prolonged exposure to harsh environments, including extreme temperatures, moisture, and mechanical stress.

Their resistance to cracking, warping, and degradation ensures long service life and reliable performance.

Chemical Resistance

Weldable plastic sheets are highly valued for their exceptional chemical resistance, which allows them to withstand exposure to a wide variety of corrosive substances without degrading or losing structural integrity.

Materials like HDPE, polypropylene, and PVC exhibit strong resistance to acids, alkalis, solvents, and other harsh chemicals commonly encountered in industrial environments.

This property makes weldable plastic sheets ideal for use in chemical processing plants, storage tanks, and piping systems where durability against chemical attack is crucial.

Toughness

Toughness is a critical property of weldable plastic sheets, reflecting their ability to absorb energy and resist fracture under stress.

Materials like HDPE and ABS exhibit exceptional toughness, making them suitable for applications where impact resistance and durability are essential.

These plastics maintain their structural integrity even under heavy load or sudden shocks, preventing cracks and deformation.

Fabrication And Processing Methods

Easy fabrication and welded welding add to their appeal for applications requiring strength, reliability, and security.

Various methods such as butt welding, hot air welding, and CNC machining are employed to customize these sheets for specific needs.

Butt Welding

Butt welding is a highly effective technique specifically designed for joining weldable plastic sheets by heating and pressing their edges together until they fuse into a single, continuous piece.

This process generates a strong, durable joint that maintains the material’s original properties, including high impact strength and chemical resistance.

Unlike other welding methods that require additional materials such as welding rods, butt welding relies solely on the plastic sheets themselves, ensuring a clean and seamless finish without compromising the quality or appearance of the fabricated product.

By combining strength, durability, and aesthetic appeal, butt welding remains a preferred choice in industrial fabrication, contributing significantly to the overall performance and longevity of weldable plastic sheet products.

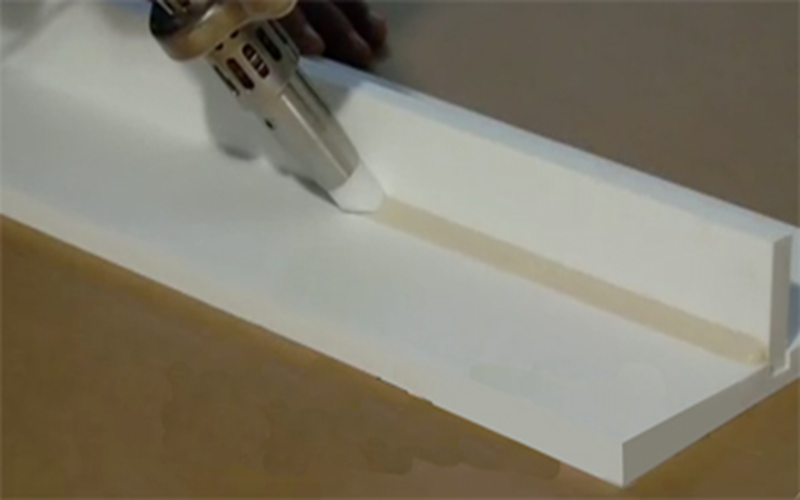

Hot Air Welding

Hot air welding is a widely used technique for joining weldable plastic sheets by applying a stream of heated air to soften the edges of the sheets, allowing them to be pressed together to form a strong, seamless bond.

This method often incorporates the use of a compatible welding rod, which melts along with the sheet edges to reinforce the joint and enhance its durability.

Hot air welding is especially effective for materials like PVC, polypropylene, and acrylic sheets, offering excellent chemical resistance and maintaining high impact strength in the finished weld.

CNC Machining

CNC machining plays a crucial role in the fabrication of weldable plastic sheets by offering unparalleled precision and efficiency.

This automated process uses computer-controlled cutting tools to shape and cut plastic sheets with exact dimensions and fine tolerances, ensuring consistent quality across production batches.

CNC machining is especially beneficial when working with complex designs or intricate patterns that require high accuracy, which manual methods cannot reliably achieve.

Applications Of Weldable Plastic Sheets

Their durability and versatility make weldable plastic sheets valuable across various industries. These materials enhance functionality and reliability in applications ranging from aquaculture to construction and signage.

Aquaculture

In the aquaculture industry, weldable plastic sheets play a crucial role in the fabrication of durable and reliable water tanks, ponds, and containment systems.

Their exceptional chemical resistance and high impact strength make them well-suited to withstand the harsh aquatic environment, including exposure to moisture, chemicals, and varying temperatures.

Using butt welding techniques, these plastic sheets can be joined with precise pressure and heat application to create seamless, watertight joints that ensure no leakage and maintain structural integrity over time.

Construction

In the construction industry, weldable plastic sheets have become essential materials due to their exceptional durability, chemical resistance, and ability to withstand a wide temperature range.

These sheets are widely used for moisture barriers, wall cladding, and protective panels, providing long-lasting protection against environmental factors such as water infiltration, UV exposure, and chemical corrosion.

Displays

Their flexibility makes weldable plastic sheets ideal for signage and displays, allowing easy molding into various shapes.

Their ability to be easily molded and shaped ensures they meet specific size requirements for various display applications.

This makes them ideal for creating visually appealing and durable blue, yellow, red, and black signs, highlighting the advantages of their design with cylinders, all while adhering to a standard efficiency.

Summary

Weldable plastic sheets offer a unique combination of strength, durability, and versatility, making them indispensable in various industries.

Their high impact strength, chemical resistance, and toughness ensure they perform reliably under demanding conditions.

The ability to fabricate and process these sheets easily, combined with their environmental benefits, makes them a sustainable and efficient choice for numerous applications.

Embracing weldable plastic sheets can lead to innovative solutions and a greener future.