Clear sheets are highly versatile, transparent materials that have become essential across a wide range of industries, from construction to creative arts.

Their lightweight nature, exceptional durability, and cost-effectiveness make them a superior alternative to traditional glass in many applications.

This article provides a comprehensive overview of the different types of clear plastic sheets, exploring their unique properties and diverse uses to help you choose the right material for your project.

What Is Clear Plastic Sheet?

Clear plastic sheet is a type of rigid or flexible plastic material that offers transparency similar to glass but with added benefits such as lightweight, impact resistance, and versatility.

Clear sheets can be formed, bent, and injection molded into different shapes and sizes, making them well suited for a wide range of jobs from protective barriers to decorative panels.

These sheets can be exposed to outdoor conditions for long periods without significant degradation, especially when treated with UV stabilizers to protect against yellowing and cracking. Their lightweight nature compared to glass also reduces handling difficulty and shipping costs.

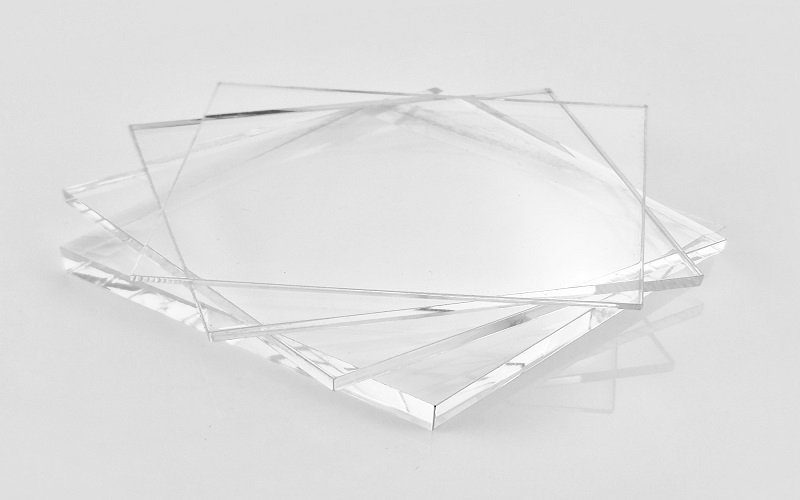

Clear plastic sheets are stocked in various thicknesses and forms, including rods and tubes, to meet the specific needs of different projects.

As a category of industrial plastics, clear plastic sheets encompass a diverse range of types and specialized uses across various industries.

Understanding the characteristics of each type of transparent plastic sheet and how they perform under different conditions is essential to selecting the right material for your job.

Working With Clear Plastic Sheet

When working with clear plastic sheets, it’s essential to use the right tools, such as a scoring tool, to avoid scratches and breakage.

Proper cutting and drilling techniques are crucial, with equipment like a table saw fitted with a blade designed specifically for plastics or a drill press using appropriate drill bits to prevent cracking or chipping.

Clear plastics can be susceptible to damage if handled improperly, so taking care to minimize stress and avoid sharp impacts is important.

Additionally, wearing protective gear such as safety glasses and gloves is vital to ensure personal safety during fabrication.

Using the correct materials and techniques not only helps maintain the clarity and durability of the plastic but also ensures a successful and professional-quality project outcome.

Main Types Of Clear Plastic Sheet

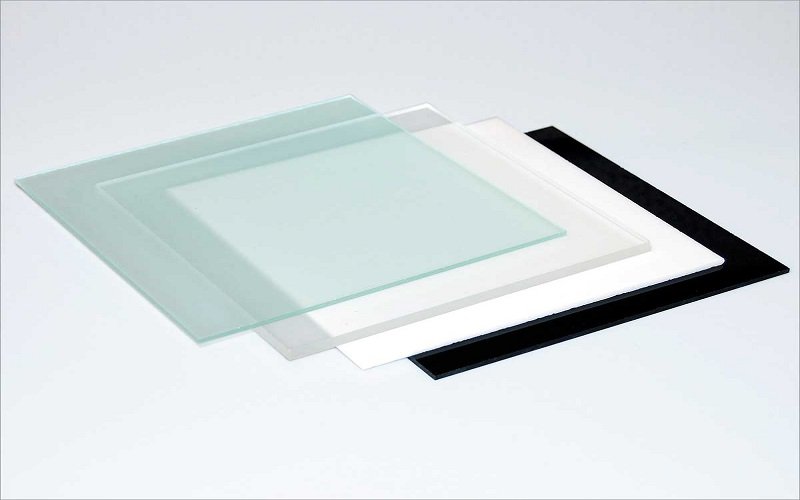

These sheets are typically made from many different types of plastic materials including acrylic, polycarbonate, PVC, and PETG, each with unique properties suited for various applications.

Acrylic Sheet (Plexiglass)

Acrylic sheets, also known by brand names like Plexiglas®, are prized for their exceptional optical clarity and excellent abrasion resistance.

It can also be drilled using appropriate drill bits and techniques to avoid cracking or chipping.

It is lightweight—about half the weight of glass—and resistant to yellowing and UV damage, making it ideal for applications requiring long-term clarity, such as picture frames, signs, and display cases.

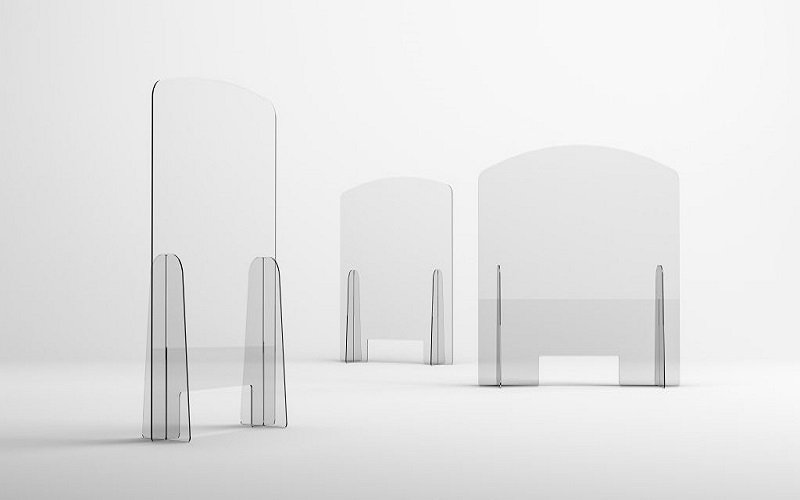

In response to the COVID-19 pandemic, acrylic sheets have become a go-to material for creating safety partitions, desktop barriers, sneeze guards, and other protective shields.

Polycarbonate Sheet (Lexan)

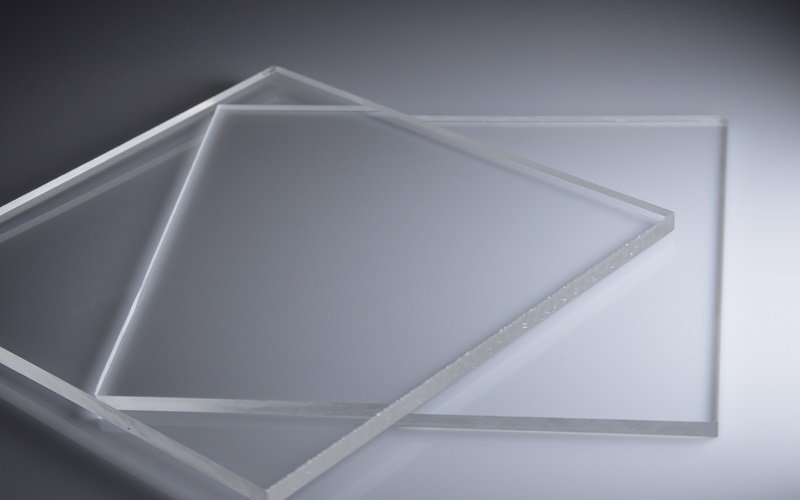

Polycarbonate sheets are renowned for their outstanding impact resistance and abrasion resistant surface, being over 200 times stronger than glass and significantly tougher than acrylic of the same thickness. They are also thermoplastics, allowing for easy molding and forming.

Polycarbonate is well suited for applications demanding durability and security, such as protective barriers, safety windows, and greenhouse panels. Some PC sheets come with UV protective layers to enhance outdoor performance.

PVC (Polyvinyl Chloride) Sheet

PVC, a versatile thermoplastic, ranks as the world’s third most widely used thermoplastic by volume, following polyethylene and polypropylene. Clear PVC sheets are valued for their robust chemical resistance, durability, and affordability.

Although less transparent than acrylic or polycarbonate, they are ideal for protective barriers and industrial applications where resistance to chemical exposure is critical.

PETG (Polyethylene Terephthalate Glycol) Sheet

PETG plastic sheets are transparent plastic materials made from amorphous copolyester, utilizing 1,4-cyclohexanedimethanol (CHDM) to partially replace ethylene glycol. This modification inhibits crystallization, enhancing transparency and processing performance.

PETG sheets exhibit outstanding toughness and high impact resistance, with an impact strength 3 to 10 times greater than that of modified polyacrylates. They offer a wide processing range, high mechanical strength, and excellent flexibility.

Compared to PVC, PETG provides superior transparency, better gloss, easier printability, and environmental advantages.

Understanding the differences among these types of clear plastic sheets—including their abrasion resistance, impact strength, clarity, and chemical resistance—will help you select the most suitable material for your specific project needs.

Applications Of Transparent Plastic Sheet

Transparent plastic sheets are versatile, finding applications across multiple industries. Combining clarity, strength, and lightweight properties, they offer both practicality and aesthetic appeal.

Windows and Enclosures

As a glass alternative, transparent plastic sheets are ideal for industrial enclosures, machine guards, and greenhouse walls, offering both impact resistance and light transmission.

Signage and Display Cases

Acrylic and polycarbonate sheets, known for their excellent optical clarity and durability, are widely used in signage and display cases, providing a robust and visually appealing solution.

Outdoor Applications and Fencing

With weather resistance and UV protection, these sheets are suitable for fencing, skylights, and protective covers, capable of withstanding harsh environments over extended periods.

Containers and Industrial Uses

Materials like PVC and high-density polyethylene resist acids and alkalis, making them ideal for manufacturing containers and industrial components that are both sturdy and durable.

Furniture and Decorative Panels

In interior design, transparent plastic sheets are used to create modern furniture and decorative panels, blending aesthetics with lightweight, shatter-resistant properties.

Understanding these applications helps in selecting the appropriate material, ensuring durability, safety, and aesthetic appeal for your project.

How To Choose Right Clear Plastic Sheet Type For Your Project?

Selecting the appropriate type of clear plastic sheet depends on several factors related to your specific project needs. Consider the following key aspects to make an informed decision:

For more information or personalized assistance in selecting the right clear plastic sheet, contact our team of plastics experts today.

1. Clarity and Optical Quality

If your project requires superior transparency and excellent light transmission, acrylic sheets are often the best choice. They provide crystal-clear clarity comparable to glass and resist yellowing over time, making them ideal for display cases, picture frames, and signage.

2. Impact Resistance and Durability

For applications where strength and toughness are critical—such as protective barriers, safety windows, or areas prone to breakage—polycarbonate sheets excel. They offer exceptional impact resistance, being significantly stronger than acrylic and glass, while maintaining good clarity.

3. Chemical Resistance

When exposure to chemicals is a concern, PVC and HDPE sheets are well suited due to their robust chemical resistance. These materials are frequently used in industrial settings or for containers that must withstand acids, alkalis, or other corrosive substances.

4. Flexibility and Forming Capabilities

If your project involves thermoforming or bending, PETG and acrylic sheets provide excellent formability without compromising clarity. Acrylic can be heated and reshaped easily, while PETG offers superior toughness and flexibility.

5. Environmental Exposure

Consider the environmental conditions the plastic will face. Both acrylic and polycarbonate can be treated with UV stabilizers to resist yellowing and degradation when exposed to sunlight for long periods, making them suitable for outdoor applications such as greenhouse panels and fencing.

6. Budget Constraints

Cost is always a factor. Acrylic is generally more affordable than polycarbonate, but polycarbonate’s durability may justify the higher price in demanding applications. PVC and HDPE offer budget-friendly options where clarity is less critical.

7. Specific Application Requirements

Certain projects may have unique needs, such as the need for abrasion resistance, scratch resistance, or compatibility with food-grade standards. Review the material specifications carefully to ensure compliance.

By evaluating these factors, you can confidently choose the right type of clear plastic sheet to ensure your project’s success, balancing performance, aesthetics, and cost-effectiveness.

Conclusion

Different types of clear plastic sheets each offer unique properties and application areas.

Acrylic, with its exceptional transparency, is ideal for signage and display cases; polycarbonate, known for its superior impact resistance, is the preferred choice for safety barriers and outdoor applications;

PETG combines fabrication flexibility and durability, making it widely used in medical equipment and retail displays; PVC, valued for its chemical stability and cost-effectiveness, is well-suited for industrial uses.

Selecting the appropriate clear plastic sheet requires a comprehensive evaluation of project requirements for transparency, durability, ease of fabrication, and environmental adaptability, while also considering budget constraints.

A thorough understanding of each material’s characteristics ensures an optimal balance of functionality, aesthetics, and cost for your project.