With a wide range of acrylic sheet types—differing in production methods, optical properties, colors, and functionalities—selecting the appropriate type is critical to meet specific project requirements.

Choosing the right acrylic sheet ensures optimal performance, cost-efficiency, and aesthetic appeal for applications ranging from signage to medical equipment.

This article provides a comprehensive guide to different types of acrylic sheet, their properties, and applications, empowering readers to make informed decisions for projects ranging from signage to medical equipment.

Overview Of Acrylic Sheets

Acrylic is an abbreviation for polymethyl methacrylate and Plexiglas® is one of the many brand names of this plastic. Over time, this brand name has become generic as ‘plexiglass’.

Their exceptional clarity, impact resistance, and weatherability make them a preferred alternative to glass across diverse industries, including various industries such as architecture, retail, and healthcare. Acrylic sheets are also incredibly versatile materials, suitable for a wide range of applications.

Main Properties

Acrylic sheets boast high transparency, with up to 92% light transmission, surpassing most glass types and being significantly lighter than ordinary glass.

They offer glass-like clarity, closely resembling glass in appearance while providing the added benefits of reduced weight and increased impact resistance.

Additionally, acrylic is easy to fabricate, allowing for cutting, drilling, bending, and thermoforming with minimal effort, making it ideal for customized designs.

General Applications

Due to their versatility, acrylic sheets are widely used across industries for indoor and outdoor applications.

Common applications include advertising signage and illuminated displays, architectural elements like windows and skylights, medical equipment such as protective shields and incubator covers, and creative uses in art installations and retail showcases.

Classification Of Acrylic Sheets

Acrylic sheeting is well-known for its wide selection of colors, glossy appearance, durability, and high resistance to various forms of wear and tear. However, acrylic sheets are also available in an extensive range of types and grades, each offering different properties.

Acrylic sheets can be broadly classified, offering a wide array of options based on their manufacturing process, physical properties, and intended applications. This classification helps users select the most suitable type of acrylic sheet for their specific needs, ensuring optimal performance and longevity.

1. By Manufacturing Process

Acrylic sheets are primarily produced through two methods: cast acrylic and extruded acrylic.

Cast Acrylic Sheet

Manufactured by pouring liquid acrylic monomer into molds where it solidifies, cast acrylic sheets are known for their superior optical clarity, excellent weather resistance, high impact resistance, and superior strength.

They are ideal for applications requiring various shapes and customized designs due to their ease of fabrication and ability to maintain structural integrity over time.

Extruded Acrylic Sheets

Produced by continuously pushing acrylic resin through a die, extruded acrylic sheets offer consistent thickness and are generally more affordable.

While they maintain good optical clarity and UV resistance, they tend to be less impact resistant and may turn yellow faster when exposed to prolonged direct sunlight compared to cast acrylic.

2. By Optical and Surface Properties

Acrylic sheets also vary by their surface finish and light transmission characteristics, including clear sheeting as a key category, as well as:

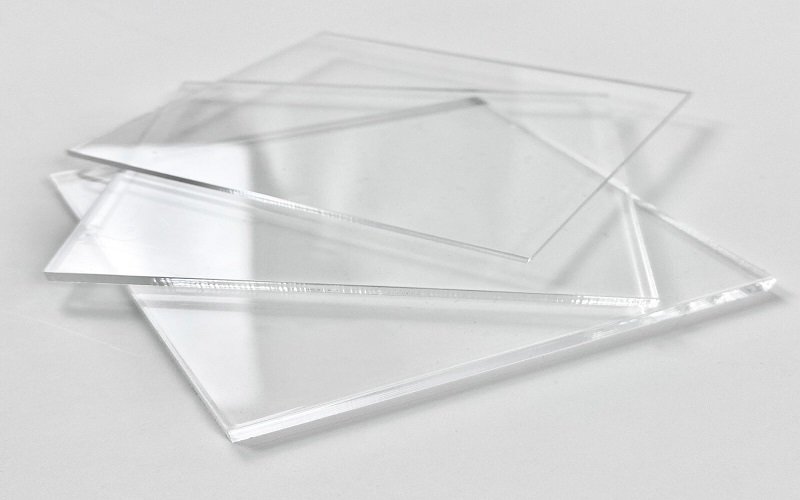

Clear Acrylic Sheet

Clear acrylic sheet, also commonly referred to as clear acrylic sheeting, is known for high optical clarity and light transmission. These clear acrylic sheets are incredibly versatile materials suitable for a wide range of applications, including glazing, display cases, and lighting fixtures.

Compared to other materials such as glass and polycarbonate, clear acrylic sheets offer superior impact resistance, lightweight properties, and enhanced durability, making them a preferred choice for many uses.

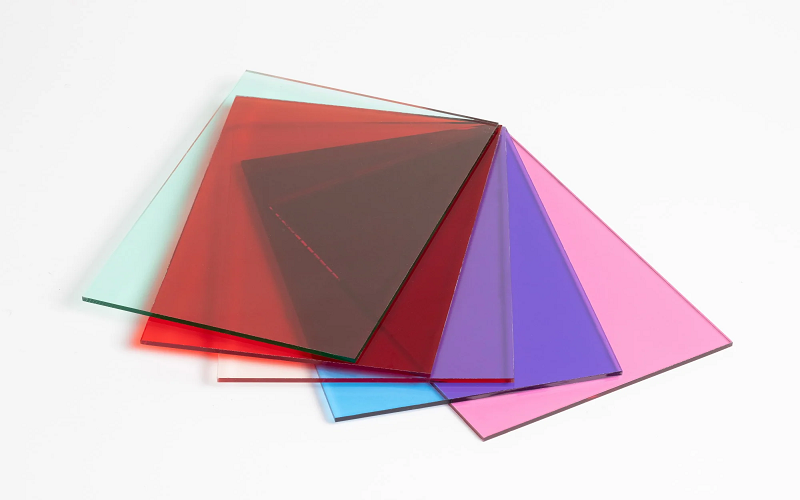

Colored Acrylic Sheets

These sheets are infused with vibrant pigments, and acrylic maintains its clarity and translucency even when colored, providing decorative accents without compromising structural integrity.

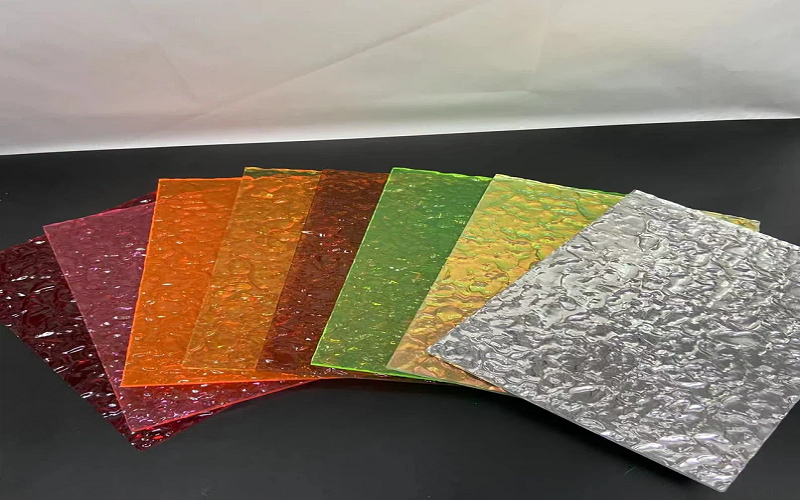

Textured Acrylic Sheets

Featuring embossed or debossed surfaces, textured surfaces are a defining feature of textured acrylic sheets, offering privacy and unique aesthetic appeal by diffusing light and reducing glare.

Mirrored Acrylic Sheeting

Acrylic mirrors, also known as mirror acrylic, are a durable alternative to traditional mirrors. Combining the reflective properties of glass mirrors with the lightweight and shatter-resistant benefits of acrylic, these sheets are perfect for interior decoration and safety applications.

Light Diffusing Acrylic Sheets

Designed to evenly distribute light, with light diffusion as their primary function, these sheets prevent hot spots and luminance fluctuations, enhancing the visual impact of illuminated signs and displays.

The frosted surface diffuses light, reducing glare and reflection, making it ideal for applications such as privacy screens, partitions, decorative panels, and lighting fixtures.

3. By Functional Coatings and Treatments

Certain acrylic sheets are enhanced with specialized coatings, such as abrasion resistant coating, to improve performance in specific environments:

Abrasion Resistant Acrylic Sheets

Coated with a durable abrasion resistant layer, these sheets protect against scratches and chemical damage, offering excellent chemical resistance to oils, solvents, and acids, ideal for high-traffic areas.

Anti-Static Acrylic Sheeting

Featuring a permanent coating that dissipates static electricity, these sheets prevent dust accumulation and protect sensitive electronic components.

Solar Tinted Acrylic Sheets

Tinted to block harmful UV rays and reduce heat buildup, these sheets enhance comfort and protect interior furnishings without compromising visible light transmission.

Non-Glare Acrylic Sheeting

With a matte finish that reduces reflections and glare, non-glare acrylic sheets offer the same durability as standard acrylic while improving visibility in bright environments.

4. Specialized Acrylic Sheets

Impact Modified Acrylic Sheets: Engineered to offer enhanced impact resistance while maintaining optical clarity and weather resistance, these sheets provide a cost-effective alternative to polycarbonate. Compared to ordinary glass, impact modified acrylic sheets are significantly more durable and less prone to shattering, making them ideal for demanding environments.

Lucite Block Acrylic Sheets: Lucite block acrylic sheeting is a specialized type of sheeting that makes it possible to embed LED lighting directly into the acrylic material. These sheets are also highly suitable for outdoor applications due to their excellent weather resistance and durability.

By understanding the classification of acrylic sheets, users can make informed choices that align with their project requirements, balancing factors such as durability, aesthetics, and cost-effectiveness. Selecting the right specialized acrylic sheet ensures you have the perfect material for your unique needs.

How To Choose Acrylic Sheets For Project?

Choosing the right acrylic sheet for your project involves considering several key factors to ensure optimal performance and aesthetics.

Start by evaluating the specific requirements of your application, such as the desired level of transparency, impact resistance, and weatherability. For projects requiring complex shapes or intricate designs, cast acrylic sheets are often preferred due to their superior machinability and ability to maintain structural integrity.

Consider the environment in which the acrylic will be used. For outdoor applications exposed to direct sunlight, selecting UV-resistant cast acrylic or solar tinted acrylic sheets will help prevent yellowing and degradation over time. If glare reduction is important, non-glare acrylic sheeting with a matte finish can improve visibility without sacrificing clarity.

For applications requiring enhanced durability, abrasion resistant acrylic sheets with a protective coating offer excellent resistance to scratches and chemical exposure. In environments sensitive to static electricity, anti-static acrylic sheeting can prevent dust accumulation and protect electronic components.

Color and aesthetic considerations also play a vital role. Colored acrylic sheets provide vibrant decorative accents while maintaining strength, whereas textured acrylic sheets add privacy and unique visual appeal through their patterned surfaces. Mirrored acrylic sheeting offers a lightweight, shatter-resistant alternative to glass mirrors, suitable for interior decoration and safety applications.

Finally, assess the fabrication and budget constraints of your project. Extruded acrylic sheets are generally more cost-effective and suitable for standard applications, while cast acrylic sheets, though pricier, deliver higher optical clarity and durability.

By carefully weighing these factors—application needs, environmental conditions, aesthetic preferences, and budget—you can select the perfect type of acrylic sheet that meets your project’s demands, ensuring both functionality and visual appeal.

Summary

In summary, acrylic sheets offer a wide range of options tailored to meet specific project needs. From clear and colored sheets to more specialized variants like anti-static and impact modified acrylic, each type brings unique properties and benefits to the table.

Choosing the right acrylic sheet can significantly enhance the functionality and aesthetics of your project.

Whether you’re looking to create a stunning display, protect sensitive equipment, or add a decorative touch, there’s an acrylic sheet that’s perfect for your needs. Embrace the versatility and practicality of acrylic sheets and let your creativity shine!