Polycarbonate sheets have become a popular choice in various industries due to their outstanding durability, versatility, and optical clarity.

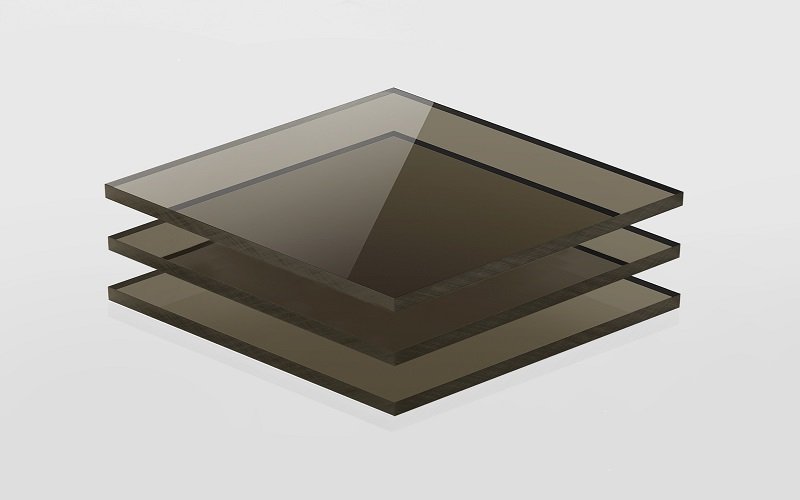

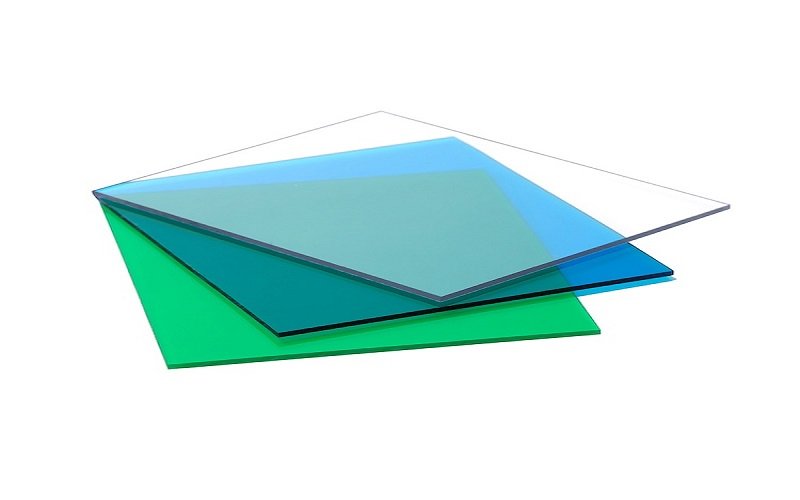

Among the different types available, tinted polycarbonate sheets offer unique advantages by combining the strength of polycarbonate with the benefits of color tinting.

These sheets not only enhance aesthetic appeal but also provide essential features such as UV protection, heat resistance, and improved light transmission control.

Whether used in construction, signage, machine guards, or windows, tinted polycarbonate sheets deliver reliable performance while meeting diverse project requirements.

In this article, we will explore the key benefits, applications, and features of tinted polycarbonate sheets to help you make an informed decision for your next project.

What Is Tinted Polycarbonate Sheet?

Tinted polycarbonate (Lexan) sheet is a type of plastic sheet made from polycarbonate (PC) plastic material, with pigments or dyes added to give it different colors such as red, blue, green, yellow, and more.

It retains the excellent physical properties of polycarbonate, including high strength, impact resistance, heat resistance, and UV resistance.

At the same time, the color tint effectively reduces light transmission and heat conduction, enhancing the sheet’s shading and insulation performance.

This makes tinted polycarbonate sheets widely used in various fields such as construction, industrial applications, transportation, and advertising signage, meeting both functional requirements and improving visual appeal.

Advantages and Features of Tinted Polycarbonate Plastic Sheets

Tinted polycarbonate plastic sheets combine the inherent advantages of polycarbonate with the added benefits of tinting.

Exceptional Strength and Durability

These sheets are known for their exceptional tensile strength and durability, making them suitable for demanding industrial and construction applications.

Integrated Pigments With UV Protection

The tinting process involves integrating pigments directly into the polycarbonate material during manufacturing, ensuring consistent color and enhanced UV resistance that helps prevent yellowing and degradation from prolonged sun exposure.

Light Transmission Controllability

One of the key features of tinted polycarbonate sheets is their ability to filter and reduce light transmission, which helps control glare and heat gain. This makes them ideal for use in environments where managing sunlight and temperature is critical, such as skylights, canopies, and windows.

Variety of Colors

The sheets are available in a variety of colors, including bronze, grey, blue, yellow, and orange, allowing for both functional and aesthetic customization.

Excellent Thermal Expansion

In addition to their strength and color options, tinted polycarbonate sheets exhibit excellent thermal expansion properties, allowing them to expand and contract with temperature changes without cracking or warping.

Fabrication Flexibility

They can be easily cut, shaped, molding and thermoformed into different shapes and sizes to meet specific project requirements.

Custom Dimensions and Modifications

Whether you need an exact size sheet or custom dimensions with holes or other modifications, tinted polycarbonate sheets offer the flexibility to accommodate diverse fabrication needs.

Lightweight and Easy to Handle

Moreover, these sheets are lightweight compared to glass or acrylic alternatives, making them easier to handle and install while maintaining superior impact resistance.

Easy Maintenance and Cleaning

Cleaning polycarbonate sheets is straightforward, requiring only mild soap and water to maintain their clarity and surface quality.

Overall, tinted polycarbonate plastic sheets provide a durable, versatile, and visually appealing solution for a wide range of applications, combining safety, functionality, and design flexibility in one high-quality material.

Nominal Size For Tinted Polycarbonate Sheets

The nominal size of tinted polycarbonate sheets typically refers to their standard width, length, thickness, and weight.

These dimensions can vary depending on the manufacturer and specific product line. Below is a summary table of common nominal sizes:

| Dimension | Typical Range | Notes |

|---|---|---|

| Width | 48 inches (1220 mm) to 72 inches (1830 mm) | Standard widths vary by manufacturer |

| Length | 96 inches (2440 mm) to 144 inches (3660 mm) | Length options provide flexibility for projects |

| Thickness | 1/16 inch (1.5 mm) to 1/4 inch (6 mm) or more | Thickness affects impact resistance and flexibility |

| Weight | Varies with thickness and size | Polycarbonate sheets are lightweight compared to glass |

When ordering tinted polycarbonate sheets, customers can often specify exact size sheets with custom dimensions, including cut-to-size options, holes, and other modifications to suit various project requirements.

It is important to consider the nominal size in relation to the intended use. Thicker sheets offer increased impact resistance and durability, making them suitable for heavy-duty applications.

Conversely, thinner panels provide more flexibility and reduced weight, ideal for projects where ease of handling or shaping is a priority.

Additionally, the nominal size influences the price and shipping options, so selecting the appropriate dimensions can help save on costs and facilitate easier mounting or forming during installation.

Applications Of Polycarbonate Tinted Sheets

- Construction: Used for skylights, roofs, partitions, curtain walls, etc., providing both aesthetic appeal and functionality.

- Advertising Industry: Used for lightboxes, signs, display boards, leveraging its light transmission and color effects.

- Industrial Applications: Used as machine guards, equipment housings, combining safety and aesthetics.

- Decorative Design: Interior and exterior decoration, such as colored partitions and furniture surfaces.

- Transportation: Used for windows, windshields, commonly found in automobiles, trains, or ships.

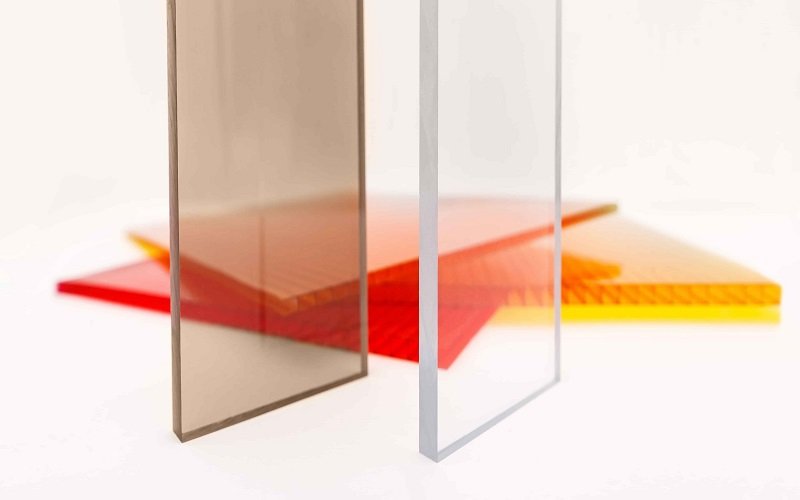

Comparison Of Tinted Polycarbonate Sheets And Transparent Polycarbonate Sheets

Colored polycarbonate sheets and clear polycarbonate sheets each have their own advantages in terms of performance and applications, and the choice depends on the specific project requirements.

Light Transmission and Shading Effect

Clear polycarbonate sheets feature very high light transmission, typically over 85%, making them suitable for situations where maximum natural light access is desired.

On the other hand, tinted polycarbonate sheets contain integrated pigments that reduce light transmission, effectively minimizing glare and UV radiation, making them ideal for environments requiring shading and sun protection.

UV Resistant Protection

While clear polycarbonate sheets usually come with a UV resistant coating, tinted polycarbonate sheets inherently block UV rays more effectively due to their pigment content. This enhanced UV resistance helps prevent yellowing and performance degradation, thereby extending the material’s service life.

Heat Control

Tinted polycarbonate sheets perform better in reducing solar heat transmission, helping to lower indoor temperatures and improve energy efficiency. This makes them well-suited for applications such as building roofs, skylights, and other areas where temperature control is critical.

Aesthetics and Privacy

Tinted polycarbonate sheets offer a variety of color options to meet diverse design needs and also provide a degree of visual privacy.

In contrast, clear polycarbonate sheets are ideal when unobstructed visibility and maximum light access are required.

In summary, the choice between tinted and clear polycarbonate sheets should be based on the project’s specific needs regarding light control, UV resistant protection, heat management, aesthetics, and privacy.

Conclusion

In summary, tinted polycarbonate sheets are an ideal choice for demanding applications, combining exceptional durability, UV resistance, and customizable colors, outperforming other products such as clear polycarbonate or fragile glass alternatives.

Renowned brands under MUDUSA, including Lexan®, offer tinted polycarbonate sheets in various thicknesses and flexible quantities to suit projects of any scale, ensuring cost-effective, lightweight solutions that enhance safety, aesthetics, and energy efficiency in construction, signage, and industrial uses.

Whether purchasing in bulk or custom panels, tinted polycarbonate sheets from trusted brands provide reliable long-term value.