Unlocking the secrets of styrene sheets reveals the incredible versatility and wide-ranging applications of this remarkable plastic material.

From its chemical composition to its physical properties, styrene sheets have become a cornerstone in industries such as manufacturing, packaging, construction, and creative arts.

In this article, we will delve into the types, properties, benefits, and practical uses of styrene sheets, providing a comprehensive guide to help you unlock their full potential.

What Are Styrene Sheets?

Styrene sheets are versatile plastic materials primarily made from polystyrene, a synthetic thermoplastic polymer renowned for its durability, impact strength, and ease of fabrication.

These sheets are widely utilized across numerous industries due to their lightweight nature, smooth surface finish, and excellent dimensional stability.

Styrene sheets come in various forms, including High Impact Polystyrene, Styrene-Acrylonitrile , and other copolymers such as acrylonitrile butadiene styrene and styrene butadiene rubber, each offering unique properties tailored to specific applications.

Their adaptability enables their use in manufacturing component parts, indoor signs, foodservice containers, food packaging, toys, insulation materials, and even polystyrene foam products.

Available in a broad range of thicknesses and sizes, styrene sheets are easy to cut, shape, bond, and recycle, making them an ideal choice for both industrial and creative projects.

Types Of Styrene sheets

Styrene sheets come in several distinct types, each designed to meet specific performance requirements and applications.

High Impact Polystyrene (HIPS) Sheet

High Impact Polystyrene (HIPS) sheets are a popular choice in the plastics industry due to their exceptional toughness and impact strength.

These sheets combine the lightweight nature of polystyrene with enhanced resilience, making them ideal for applications that demand durability and reliability.

HIPS sheets are widely used in manufacturing component parts, indoor signs, packaging materials, and foodservice containers because they provide excellent dimensional stability and are easy to fabricate.

Styrene Acrylonitrile (SAN) Sheet

Styrene Acrylonitrile (SAN) sheets are a copolymer blend of styrene and acrylonitrile, offering enhanced thermal resistance, rigidity, and chemical stability compared to standard polystyrene sheets.

Due to these properties, SAN sheets are widely used in manufacturing industries that demand reliable, solid plastic materials with consistent performance.

Additionally, SAN sheets are easy to process, cut, and form, enabling efficient production and customization for various consumer and industrial uses.

Acrylonitrile Butadiene Styrene (ABS) Sheet

Acrylonitrile Butadiene Styrene sheets are a highly durable and impact-resistant type of styrene sheet widely used in demanding applications.

ABS combines the strength and rigidity of acrylonitrile and styrene with the toughness and flexibility provided by butadiene rubber.

Due to these properties, ABS sheets are commonly used in automotive parts, electronic housings, toys, and consumer goods that require long-lasting durability.

Styrene Butadiene Rubber (SBR) Sheet

Styrene Butadiene Rubber sheets are a specialized type of styrene-based material that combines the flexibility and elasticity of rubber with the strength and durability of styrene polymers.

This unique combination results in a material that offers excellent impact resistance and enhanced toughness, making SBR sheets ideal for applications requiring both resilience and flexibility.

Commonly used in coatings, adhesives, and protective coverings, SBR sheets provide superior performance in environments where durability and resistance to wear and tear are critical.

Styrene Butadiene Latex (SBL) Sheet

Styrene Butadiene Latex (SBL) sheets are a specialized form of styrene-based material known for their excellent flexibility, elasticity, and strong adhesion properties.

Unlike traditional rigid styrene sheets, SBL sheets incorporate latex polymers that provide enhanced resilience and durability, making them suitable for applications requiring both toughness and pliability.

Commonly used in coatings, adhesives, and protective films, SBL sheets offer superior resistance to wear, tear, and environmental factors such as moisture and temperature fluctuations.

Key Properties Of Styrene Sheets

Styrene sheets possess several key properties that make them highly versatile and widely used across various industries。

Excellent Impact Strength

One of the standout features of styrene sheets is their excellent impact strength.

This property means that styrene sheets can absorb and withstand significant force without cracking or breaking, making them highly durable and reliable for a wide range of applications.

Whether used in the manufacture of component parts, packaging, or protective coverings, the robust nature of styrene sheets ensures longevity and resistance to damage under stress.

Lightweight

Styrene sheets are renowned for their lightweight nature, which significantly enhances their usability across various industries.

This characteristic not only makes handling and transportation easier but also reduces overall project costs by minimizing shipping expenses.

Their low weight also contributes to energy efficiency in applications such as building insulation and packaging, where reducing material mass is crucial.

High Formability

Styrene sheets are renowned for their high formability, making them exceptionally easy to shape and mold into a variety of complex designs.

This property allows manufacturers and hobbyists alike to cut, bend, and thermoform the material with minimal effort, enabling the creation of precise component parts and intricate models.

Their excellent formability not only enhances production efficiency but also broadens the scope of creative possibilities, making styrene sheets a preferred choice in industries that demand both versatility and precision.

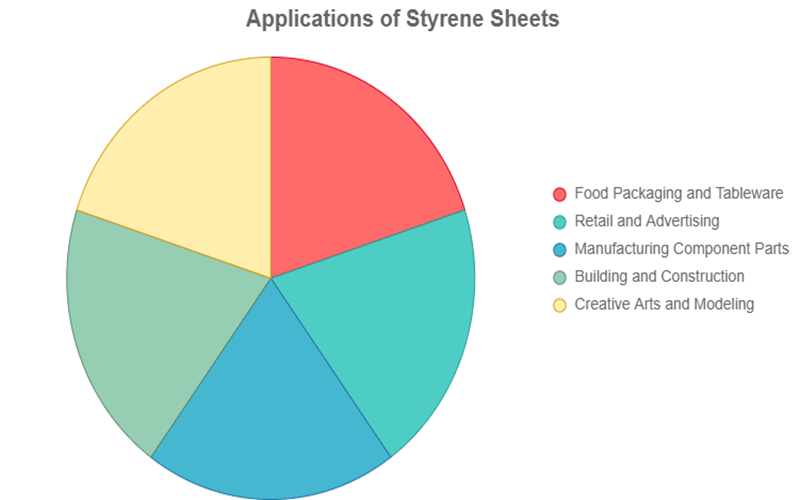

Applications Of Styrene Sheets

Styrene sheets are widely used across various industries due to their versatility and excellent properties.

Food Packaging

Styrene sheets, particularly High Impact Polystyrene (HIPS), are extensively used in the food packaging industry due to their excellent impact strength, lightweight nature, and food-safe properties.

These sheets are commonly manufactured into disposable food containers, cutlery, trays, and tableware, providing durable and hygienic solutions for foodservice containers.

The material’s ability to maintain structural integrity while being lightweight makes it ideal for packaging applications that require both protection and ease of handling.

Advertising

Styrene sheets are widely used in advertising due to their lightweight, durable, and easy-to-customize nature.

These sheets serve as an excellent substrate for indoor signs, point-of-purchase displays, and promotional materials.

Their smooth surface allows for high-quality printing and vibrant graphics, making them ideal for capturing consumer attention.

Additionally, styrene sheets can be easily cut and shaped to fit various design requirements, enabling creative and eye-catching advertising solutions.

Construction

In the construction industry, styrene sheets are valued for their lightweight, durable, and insulating properties.

They are commonly used as insulation panels, protective coverings, and vapor barriers in building projects, helping to enhance energy efficiency and structural integrity.

Their resistance to moisture and chemicals makes them ideal for use in both residential and commercial construction.

Tips For Working With Styrene Sheets

Working with styrene sheets can be a rewarding experience if you know the right techniques.

For precise cuts, it’s best to score the surface with a knife rather than cutting all the way through. This allows the sheet to snap cleanly along the scored line, ensuring a neat edge.

Organizing your workspace is also crucial for efficiency. Keeping frequently used tools within easy reach enables saving time and streamlining the distributed process.

In addition, using a sharp hobby knife blade aids in precisely picking and placing small component parts in order during model assembly, enhancing accuracy under low pressure in the world of crafting and ensuring the right quantity of human parts is used at this day point.

Note that proper organization in building can significantly improve your workflow. The value of an organized workspace cannot be overstated, as it can lead to a better result.

These tips can significantly improve your experience when working with styrene sheets, making your projects smoother and more enjoyable.

Choosing Styrene Sheets For Your Project

When selecting styrene sheets for your project, it is essential to consider several factors to ensure optimal performance and safety.

Polystyrene products, including styrene sheets, are widely recognized for their toughness and versatility, making them suitable for a variety of applications such as indoor signs, packaging, and even watercraft components.

The white color of many styrene sheets provides a clean and professional appearance, ideal for both commercial and creative uses.

Safety is a paramount concern when working with styrene sheets. Always verify that the material meets the relevant state and industry safety standards to avoid risks associated with improper use.

Additionally, consider the length and thickness of the sheets needed for your specific application, as these dimensions directly affect the material’s durability and ease of handling.

For projects involving outdoor or marine environments, such as augmenting watercraft, it is crucial to choose styrene sheets that can withstand exposure to moisture and varying temperatures.

Requesting a detailed quote from suppliers can help you compare options and select the best material for your budget and requirements.

By carefully evaluating these factors, you can unlock the full potential of styrene sheets and ensure a successful, safe, and long-lasting project.

Conclusion

Styrene sheets are a versatile and cost-effective material with numerous applications across various industries.

Their key features, such as excellent dimensional stability, impact resistance, and ease of customization, make them an ideal choice for many projects.

Known for being tough and resilient, styrene sheets provide reliable performance in demanding conditions. For more detailed specifications and technical data, you can often find product information in a downloadable PDF format from suppliers.

Despite their disadvantages, the benefits of styrene sheets in terms of versatility, ease of use, and cost-effectiveness cannot be overlooked.

They enable the creation of durable and precise components, making them invaluable in manufacturing, construction, and creative projects.

By experimenting with styrene sheets, including those used in augmenting (AUG) prototypes and models, you can discover new possibilities and innovations in your work.

Explore the potential of styrene sheets for your projects and stay informed about new developments and materials in the industry.