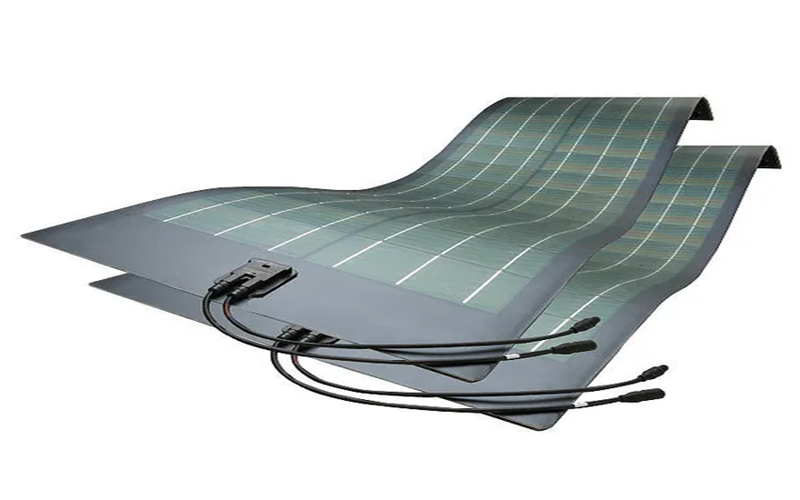

Solar plastic panels utilize advanced semiconductor materials embedded within flexible substrates, enabling them to efficiently absorb light across the solar spectrum and convert it into usable electrical energy through the photovoltaic effect.

Unlike traditional rigid solar panels made from crystalline silicon or polycrystalline silicon, solar plastic panels often incorporate thin film solar cell technology.

This article introduces solar plastic panels, exploring their unique features, benefits, and potential to transform industries by providing a versatile and cost-effective solar solution.

What Is Solar Plastic?

Solar plastic is an innovative photovoltaic material that combines the flexibility of plastic substrates with advanced semiconductor technology to create lightweight, adaptable solar panels.

The core of solar plastic panels consists of several solar cells made from semiconductor materials such as amorphous silicon or copper indium gallium selenide.

These thin film photovoltaics work by absorbing the sun’s light and converting it into electric current through the photovoltaic effect, producing DC electricity.

In addition to their adaptable design, solar plastic panels often feature an anti reflective layer and are laminated with a glass sheet or durable plastic layer to protect the delicate silicon wafers and maintain efficiency.

The inclusion of a metal frame or flexible backing ensures structural integrity while allowing for a reduced tilt angle during installation, maximizing exposure to the sun’s energy.

How Solar Plastic Is Made?

Solar plastic panels are produced through a sophisticated manufacturing process that integrates advanced photovoltaic cell technology with flexible plastic substrates.

This thin film solar cell technology significantly reduces silicon waste compared to traditional crystalline silicon panels made from single crystal silicon or melting multiple silicon crystals together to form polycrystalline cells.

After the semiconductor layers are applied, the silicon solar cells are interconnected to form a solar module or solar array, where several solar cells work together to produce more electricity efficiently.

The entire assembly is framed, often with a lightweight metal frame or flexible backing, to provide structural integrity without compromising flexibility.

This innovative manufacturing process enables solar plastic panels to produce power comparable to conventional monocrystalline solar panels and polycrystalline cells while offering advantages such as lightweight design and adaptability to curved surfaces.

Key Features Of Solar Plastic Panels

Solar plastic panels stand out for several key features that make them an innovative choice in solar technology.

Weather Resistance

Solar plastic panels are engineered to endure a wide range of environmental conditions, making them highly weather resistant.

Their durable materials, including protective layers such as ethylene vinyl acetate (EVA) film and robust plastic or glass casing, shield the delicate semiconductor layers from moisture, UV radiation, and temperature fluctuations.

This resistance ensures consistent performance even under harsh weather like heavy rain, strong winds, or intense sunlight.

Lightweight

Solar plastic panels are notably lightweight compared to traditional solar panels made with heavy glass and metal frames.

This reduced weight is primarily due to the use of flexible plastic substrates instead of rigid materials like crystalline silicon wafers and thick glass sheets.

The lightweight nature of solar plastic enables easier handling, transportation, and installation, especially on surfaces that cannot support the load of conventional solar modules.

Benefits Of Solar Plastic Sheets

Solar plastic sheets offer numerous advantages that make them an attractive option for renewable energy solutions.

Environmental Sustainability

Solar plastic sheets contribute significantly to environmental sustainability by offering a renewable energy solution that reduces reliance on fossil fuels.

Their production involves less energy-intensive processes compared to traditional crystalline silicon solar panels, leading to a smaller carbon footprint.

By converting solar radiation into clean electrical power efficiently, these sheets help decrease greenhouse gas emissions and promote cleaner air quality.

Overall, solar plastic sheets represent a sustainable alternative in solar PV technology, supporting global efforts to combat climate change and protect natural resources.

Cost Effectiveness

Solar plastic sheets provide an affordable and efficient solution for harnessing solar power, making renewable energy accessible to a wider audience.

Thanks to their innovative manufacturing process, which uses thin film solar cell technology, these sheets require significantly less silicon compared to traditional crystalline silicon panels, reducing material costs.

The production involves melting multiple silicon crystals into very thin layers, minimizing silicon waste and lowering overall expenses.

Limitations Of Solar Plastic Sheets

Despite their many advantages, solar plastic sheets have several limitations that should be considered.

Lower Energy Efficiency

One of the main challenges of solar plastic sheets is their lower energy efficiency compared to standard panels made from crystalline silicon.

While traditional monocrystalline solar panels and polycrystalline silicon cells can convert a higher percentage of the sun’s energy into electrical power, solar plastic sheets—often utilizing thin film solar panelstechnology—tend to produce less electricity per unit area.

Additionally, the anti reflective coating and glass panels used in conventional panels optimize light absorption more effectively than the flexible substrates in solar plastic sheets.

Higher Initial Costs

While solar plastic sheets offer numerous advantages, one notable limitation is their higher initial cost compared to traditional solar panels.

The use of advanced semiconductor materials like copper indium gallium selenide (CIGS) and the complexity of thin film solar cell manufacturing processes contribute to increased production expenses.

Additionally, specialized production lines and quality control measures required to ensure the durability and efficiency of these flexible panels add to the upfront investment.

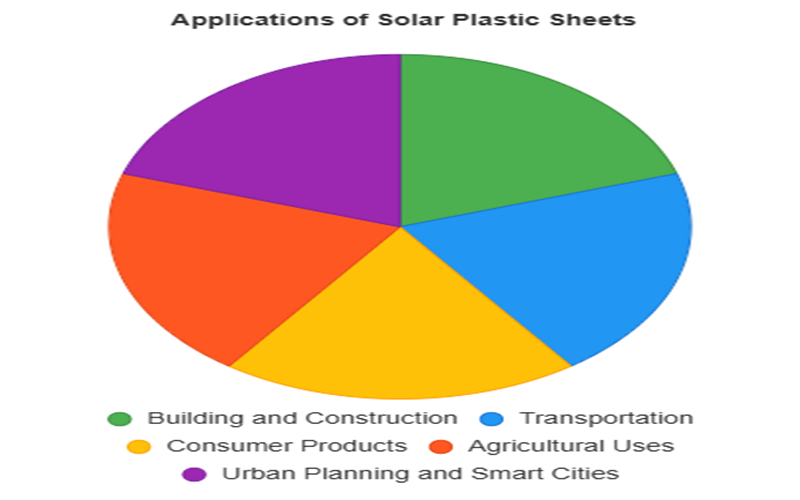

Applications Of Solar Plastic Sheets

Solar plastic sheets have a wide range of applications across various industries due to their flexibility, lightweight nature, and renewable energy capabilities.

Building

Solar plastic sheets are revolutionizing the construction industry by seamlessly integrating renewable energy generation into building materials.

These flexible, lightweight sheets can be incorporated into roofing, facades, skylights, and windows, allowing buildings to produce electricity without compromising architectural design or aesthetics.

By converting sunlight efficiently through advanced thin film solar cell technology, these sheets help buildings reduce energy costs and carbon footprints.

Moreover, their durable construction, including protective layers and anti-reflective coatings, ensures long-term performance and weather resistance.

Transportation

Solar plastic sheets are revolutionizing the transportation sector by providing lightweight, flexible, and durable solar panel components that can be seamlessly integrated into vehicles and infrastructure.

These thin film panels can be applied to the surfaces of electric cars, buses, trains, and even aircraft, enabling the continuous generation of electrical current while on the move.

By converting energy from the sun directly into usable power, solar plastic sheets help reduce reliance on traditional fuel sources and extend the range of electric vehicles.

The use of advanced semiconductor materials in these solar plastic panels ensures high performance while avoiding the inclusion of toxic elements commonly found in older technologies, promoting environmental sustainability within the transport industry.

Consumer Electronics

Solar plastic sheets are increasingly becoming a popular choice in the consumer electronics industry due to their lightweight, flexible, and durable nature.

These sheets can be seamlessly integrated into portable devices such as smartphones, tablets, and wearable technology, providing a reliable source of renewable energy.

Utilizing advanced thin film solar cell technology, these solar plastic components efficiently absorb light and convert it into electrical energy, enabling devices to conduct electricity without relying solely on traditional batteries.

Agriculture

Solar plastic sheets are transforming agriculture by providing a versatile and sustainable energy solution tailored to the unique needs of farming environments.

These flexible thin film solar panels can be seamlessly integrated into greenhouse coverings, shade structures, and even irrigation systems, enabling farms to harness solar power without disrupting essential agricultural processes.

By converting solar radiation into electrical energy through advanced photovoltaic cells, solar plastic sheets help power water pumps, lighting, and climate control systems, enhancing operational efficiency.

Future Prospects Of Solar Plastic Sheets

The future of solar plastic sheets looks exceptionally bright as ongoing advancements in solar technology continue to enhance their efficiency, durability, and versatility.

Emerging innovations such as tandem cell designs, which layer multiple photovoltaic materials to capture a broader spectrum of solar radiation, promise to significantly boost the energy conversion rates of solar plastic panels.

Additionally, the integration of quantum dots nanoscale semiconductor particles into thin film solar cells offers exciting potential to improve light absorption and overall performance while maintaining the lightweight and flexible nature of solar plastic.

Manufacturing processes are also evolving rapidly, with more sustainable and cost-effective methods being developed to reduce reliance on molten silicon and minimize silicon waste, thereby making solar plastic sheets more commercially viable and environmentally friendly.

The adoption of cutting-edge semiconductor materials like copper indium gallium selenide (CIGS) cells further enhances the efficiency and environmental sustainability of these panels.

This adaptability, combined with ongoing improvements in photovoltaic cell (PV cell) performance and manufacturing scalability, positions solar plastic sheets as a key player in the future solar power landscape.

Conclusion

The potential and versatility of solar plastic sheets are undeniable.

Their flexibility, durability, and aesthetic versatility make them a valuable addition to the renewable energy landscape, particularly when considering flexible sheets like thin film cells.

Industries are encouraged to adopt innovative, sustainable materials like solar plastic sheets.

Moreover, solar plastic sheets can help manage excess energy production by efficiently converting solar radiation into electrical power, which can be stored or redirected for various uses.

As we look towards the future, the possibilities for solar plastic sheets are vast.

From building facades to consumer products, including integration with electronic devices such as computer chips, these materials offer a wide range of applications that can revolutionize how we generate and use energy.

Frequently Asked Questions

What Are The Advantages Of Using Silicon Solar Cells In Modern Solar Panel Technology?

Silicon solar cells offer high efficiency, durability, and long lifespan, making them advantageous in modern solar panel technology.

What Are The Key Features Of Solar Plastic Sheets?

The key features of solar plastic sheets include energy generation capabilities, durability and weather resistance, a lightweight and flexible design, and aesthetic versatility. These characteristics make them suitable for a variety of applications in solar energy systems.

How Are Solar Plastic Sheets Made?

Solar plastic sheets are made by integrating photovoltaic materials into flexible substrates, utilizing high-quality EVA film to prevent oxidation, and including durable plastics such as acrylic and polycarbonate. This process ensures both efficiency and longevity in solar energy collection.

What Are The Benefits Of Using Solar Plastic Sheets?

Using solar plastic sheets offers significant benefits, including a reduction in reliance on non-renewable energy, cost-effectiveness, and versatility for various applications. These sheets also contribute to achieving sustainable building certifications, enhancing environmental responsibility.

What Challenges Do Solar Plastic Sheets Face?

Solar plastic sheets face challenges such as lower efficiency compared to traditional solar panels, cost barriers that hinder adoption, durability issues in extreme conditions, and difficulties in scaling production. These factors must be addressed to enhance their viability in the market.