PVC plastic sheets, made from polyvinyl chloride, are widely recognized for their exceptional durability, versatility, and cost-effectiveness.

This comprehensive article delves into the various types, surface characteristics, practical applications, and emerging future trends of PVC plastic sheets.

What Is PVC Plastic Sheet?

At its core, a PVC plastic sheet is made from polyvinyl chloride (PVC), a versatile and cost-effective plastic known for its exceptional durability, chemical resistance, and ability to withstand various environmental factors such as moisture, UV exposure, and temperature fluctuations.

This durable material stands out due to its adaptability across a wide range of industries, including construction, signage, automotive, and packaging.

The journey of a PVC sheet begins with the polymerization of vinyl chloride monomers, resulting in PVC resin.

This resin can then be modified with various additives, plasticizers, and fillers to enhance its mechanical properties, flexibility, and surface finish, allowing manufacturers to produce PVC sheets in multiple thicknesses, colors, and forms.

Incorporating these additives enables the creation of both rigid and flexible PVC sheets, tailored to meet the specific requirements of diverse applications, from industrial-grade panels to lightweight expanded PVC sheets ideal for displays and signage.

This high level of customization ensures that PVC plastic sheets provide reliable performance, ease of fabrication, and long-lasting durability, making them a preferred choice for businesses and individuals alike.

Types Of PVC Plastic Sheets

When it comes to PVC plastic sheets, there are several type to consider, each with its unique set of properties and ideal applications. Understanding these types will help you choose the right one for your needs.

Solid PVC Sheet

Solid PVC sheets are renowned for their durable material and excellent chemical resistance, making them highly suitable for a wide range of industrial and commercial applications.

These sheets can withstand harsh environments, including exposure to moisture, chemicals, and UV radiation, ensuring long-lasting performance and reliability.

Their robust nature makes them ideal for structural components, protective barriers, and equipment housings where strength and durability are critical.

Additionally, solid PVC sheets are easy to fabricate, cut, and bond, allowing for versatile customization to meet specific project requirements, contributing to their widespread use in various industries.

High Impact PVC Sheet

High-impact PVC sheets are engineered to withstand significant physical stress and impact, making them an excellent choice for demanding environments where durability and toughness are essential.

These sheets provide superior resistance to cracking, breaking, and wear, ensuring long-lasting performance even under heavy use.

Their robustness makes them ideal for industrial applications, protective barriers, heavy-duty signage, and environments prone to frequent handling or rough conditions.

Additionally, high-impact PVC sheets maintain excellent chemical resistance and ease of fabrication, allowing for versatile use across various industries.

Expanded PVC Sheet

Expanded PVC plastic sheets are lightweight yet sturdy, offering an excellent balance between strength and ease of handling.

These sheets are particularly popular in applications such as signage, displays, and point-of-purchase (POP) exhibits, where quick installation and portability are crucial.

Their closed-cell foam structure provides enhanced durability and excellent resistance to moisture, chemicals, and impact, making them suitable for both indoor and outdoor use.

Additionally, the smooth surface of expanded PVC sheets is ideal for painting, printing, and laminating, allowing for vibrant graphics and professional finishes.

This versatile material is available in various thicknesses, sizes, and colors, enabling customization to meet specific project requirements while maintaining cost-effectiveness and long-term performance.

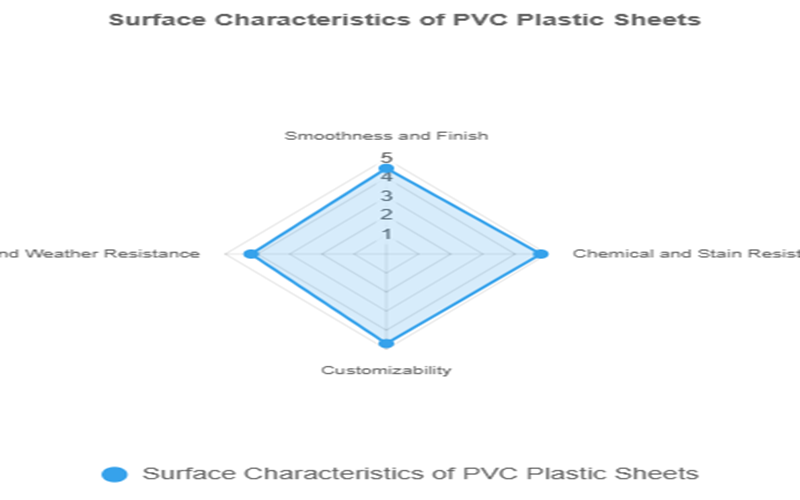

Characteristics Of PVC Plastic Sheets

The characteristics of PVC plastic sheets are another crucial aspect to consider. These characteristics can significantly influence the sheet’s performance and suitability for different applications.

Smoothness And Finish

PVC plastic sheets typically exhibit a smooth, glossy surface that enhances their aesthetic appeal, making them ideal for applications like signage, decorative panels, and displays.

The surface can be polished to achieve a high-gloss finish or textured for specific functional or visual effects, providing versatility in design.

This smooth finish also facilitates easy cleaning and maintenance, helping to keep the sheets looking new over time.

Additionally, the consistent surface quality ensures excellent adhesion for paints, laminates, and graphic overlays, making PVC sheets a preferred choice for both industrial and creative projects.

Chemical And Stain Resistance

The non-porous surface of PVC sheets provides excellent resistance to chemicals, moisture, and staining, ensuring long-lasting durability even in harsh environments such as laboratories, industrial settings, and outdoor applications.

This resistance not only protects the material from damage but also simplifies cleaning and maintenance, reducing downtime and costs.

Moreover, PVC’s chemical resistance makes it ideal for use in environments exposed to solvents, acids, and alkalis, where other materials might degrade or discolor over time.

Customizability

PVC sheets provide outstanding customizability, allowing manufacturers to create a variety of surface textures such as matte, glossy, embossed, or textured finishes to meet specific functional and aesthetic requirements.

These options enable enhanced grip, anti-slip features, or unique design elements tailored to different applications.

Furthermore, PVC sheets can be produced in an extensive range of colors, with pigments integrated throughout the material or applied as durable surface coatings that resist fading, scratches, and environmental wear.

This versatility makes PVC plastic sheets an ideal choice for industries requiring both performance and visual appeal, including signage, construction, automotive, and decorative projects.

UV And Weather Resistance

While naturally durable, PVC sheet surfaces can be enhanced with specialized UV-resistant coatings and additives to significantly improve their weatherability.

These treatments prevent yellowing, cracking, and degradation caused by prolonged exposure to sunlight and harsh environmental conditions.

As a result, treated PVC sheets maintain their aesthetic appeal and structural integrity over time, making them highly suitable for outdoor applications such as cladding, roofing, signage, and exterior displays.

This enhanced resistance extends the lifespan of PVC sheets, reduces maintenance costs, and ensures reliable performance even in challenging climates.

Benefits Of Using PVC Plastic Sheets

The benefits of using PVC plastic sheets are manifold, making them a preferred choice for many applications across industries.

PVC plastic sheets offer numerous advantages, making them a preferred material across various industries.

Their cost-effectiveness stands out, providing a budget-friendly alternative to materials like wood or metal without compromising durability.

PVC sheets are lightweight yet robust, simplifying installation and handling while ensuring long-term performance in applications like cladding or signage.

Their resistance to chemicals, moisture, and UV exposure (with proper coatings) enhances their suitability for harsh environments, reducing maintenance costs.

Additionally, PVC sheets are highly customizable in terms of color, texture, and thickness, allowing for tailored solutions in construction, medical, and consumer goods.

Their fire-retardant properties, including compliance with UL flame standards, and recyclability further contribute to their appeal, offering both safety and environmental benefits.

Moreover, PVC sheets are readily available in stock and can often be ordered with fast processing times measured in business days, ensuring timely delivery for your projects.

These combined benefits make PVC plastic sheets a reliable, versatile, and economical material choice for a wide range of applications.

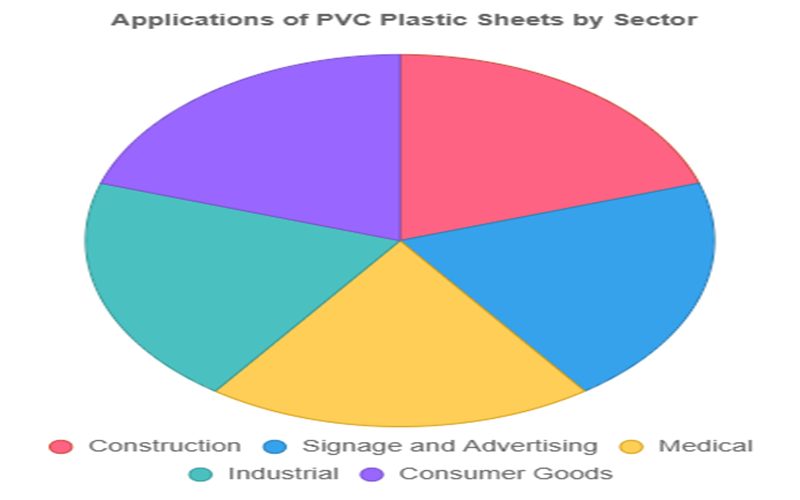

Common Applications Of PVC Plastic Sheet

PVC plastic sheets are highly versatile and widely used across various industries due to their durability, cost-effectiveness, and adaptability.

Construction

PVC plastic sheets are extensively utilized in construction for cladding, roofing, and piping due to their excellent weather resistance, chemical stability, and lightweight nature.

These properties make them ideal for exterior cladding and roofing panels that withstand harsh environmental conditions without warping or degrading.

Additionally, PVC sheets provide long-lasting performance in piping systems for water supply, drainage, and ventilation, ensuring durability and resistance to corrosion.

Their ease of fabrication and installation further enhances efficiency on construction sites, making PVC plastic sheets a cost-effective and reliable material choice for diverse building applications.

Signage And Advertising

In the signage and advertising industry, PVC sheets are a top choice for billboards, displays, and banners due to their exceptional durability and versatility.

Their smooth, matte surface allows for vibrant, high-quality printing and easy customization, ensuring eye-catching visuals that maintain brilliance over time.

PVC sheets withstand harsh outdoor conditions, including UV exposure, moisture, and temperature fluctuations, without fading, cracking, or degrading.

Additionally, their lightweight nature simplifies installation and reduces shipping costs, while their ease of fabrication allows for precise cutting and shaping to fit diverse signage designs.

These combined benefits make PVC plastic sheets a reliable and cost-effective material for impactful advertising and signage projects.

Medical

PVC plastic sheets play a vital role in the medical field, particularly for sterile packaging and the manufacture of essential equipment components.

Their non-porous, chemical-resistant surfaces ensure hygienic conditions by preventing contamination, making them ideal for packaging medical supplies and fabricating parts for diagnostic and therapeutic devices.

Additionally, PVC sheets offer excellent durability and ease of sterilization, which are critical for maintaining safety and reliability in healthcare environments.

Industrial

In industrial applications, PVC sheets serve as essential protective covers, electrical insulation, and custom fabrications tailored to specific operational needs.

Their excellent resistance to corrosion, chemicals, and wear makes them ideal for shielding machinery, insulating electrical components, and manufacturing durable parts that withstand harsh industrial environments.

Additionally, PVC sheets offer ease of fabrication and maintenance, contributing to improved safety and efficiency across various industrial sectors.

Consumer Goods

PVC plastic sheets are widely used in consumer goods for packaging, furniture, and decorative panels due to their exceptional versatility and aesthetic appeal.

Their adaptability in texture, color, and thickness allows manufacturers to create visually appealing and durable packaging solutions that protect products while enhancing shelf presence.

Additionally, PVC sheets serve as robust, low-maintenance components in furniture and decorative interior panels, offering resistance to scratches, stains, and moisture.

This combination of durability, ease of fabrication, and customizable surface finishes makes PVC plastic sheets a preferred material choice for consumer goods that demand both functionality and style.

Innovations And Future Trends Of PVC Plastic Sheet

The world of PVC plastic sheets is continually evolving, with new innovations and trends emerging regularly.

One of the most exciting developments is the advance in eco-friendly PVC formulations. These new formulations aim to reduce the environmental impact of PVC production and use, making them a safer and more sustainable form of choice.

Additionally, they help to remove some of the negative effects associated with traditional PVC and address false misconceptions about the material’s environmental footprint.

Recycling and sustainability initiatives are also gaining traction, with more companies focusing on creating recyclable PVC sheets and promoting responsible disposal practices.

These efforts often involve submitting content items such as product data and certifications to regulatory bodies and industry platforms to ensure transparency and compliance.

Moreover, emerging applications in 3D printing and smart materials are opening up new possibilities for PVC, pushing the boundaries of what this versatile material can achieve.

Summary

In summary, PVC plastic sheets offer a unique combination of durability, flexibility, and affordability. Their various types and customizable properties make them suitable for a wide range of applications, from industrial uses to artistic endeavors.

A detailed review of PVC sheets highlights their excellent performance in different environments, confirming their reliability and versatility.

When you find the right PVC plastic sheet for your project, you will appreciate the reason why this material is so widely used across industries.

When choosing PVC sheets, it is important to recognize signs of quality such as smooth surface finish, consistent thickness, and resistance to scratches and discoloration.

By understanding the different aspects of PVC sheets, from their thickness and dimensions to their surface characteristics and benefits, you can make informed decisions that enhance the success of your projects.

Let’s embrace the potential of PVC and continue to innovate for a sustainable future.