Exploring the secrets of PVC foam sheet reveals a world of versatile, durable, and lightweight materials that have transformed numerous industries.

From signage and model making to marine applications and interior design, PVC foam sheets offer unique properties that make them an ideal choice for a wide range of projects.

This introduction will guide you through the essential features, manufacturing processes, and popular uses of PVC foam sheets, helping you understand why this material continues to gain popularity among professionals and DIY enthusiasts alike.

What Are PVC Foam Sheets?

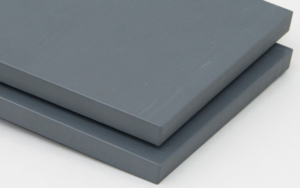

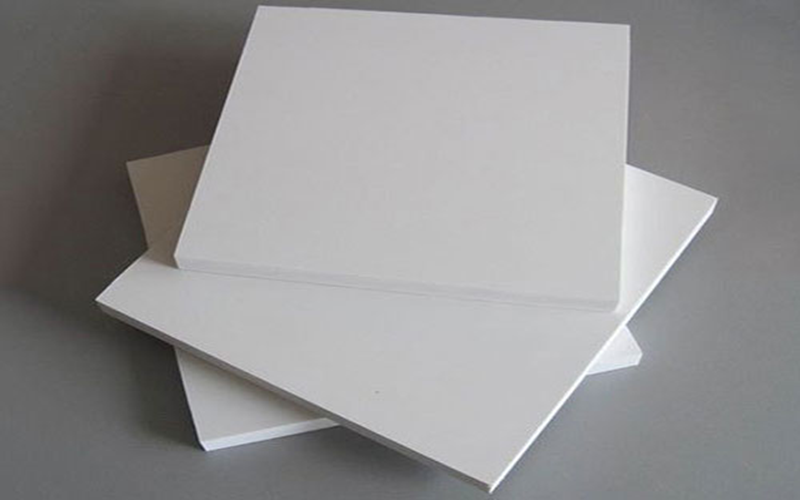

PVC foam sheets, also known as foam PVC sheets or expanded PVC foam board, are lightweight, rigid plastic panels made from polyvinyl chloride resin combined with foaming agents and additives.

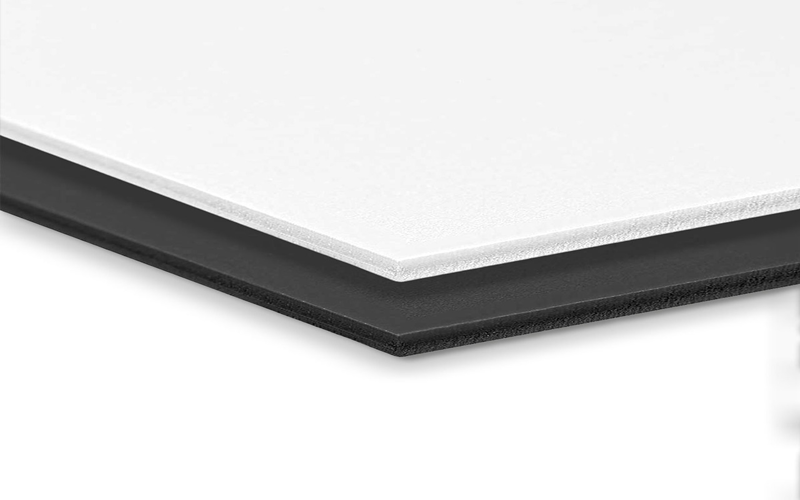

This unique composition creates a closed-cell foam structure that offers excellent durability, impact resistance, and moisture resistance.

PVC foam boards feature a smooth surface with a matte finish, making them ideal for applications such as screen printing, vinyl lettering, and lamination.

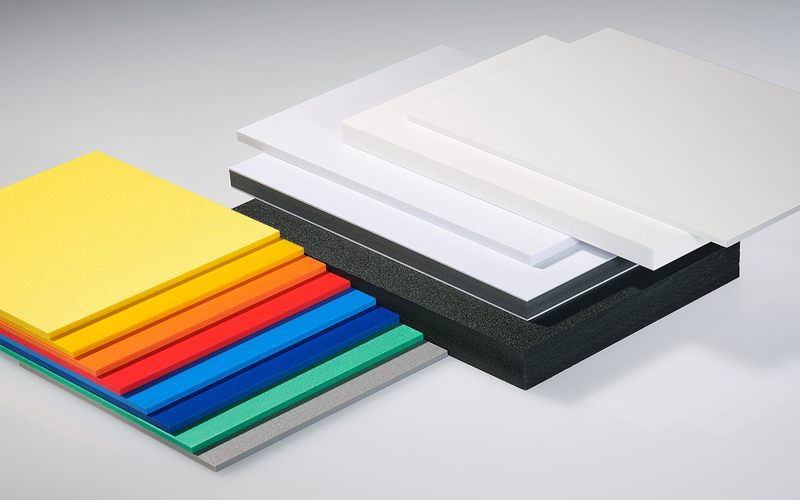

Available in various sizes and thicknesses, these sheets provide a durable and environmentally friendly solution for both indoor and outdoor applications.

Key Features Of Expanded PVC Foam Board

Expanded PVC foam board offers a range of key features that make it a preferred material across various industries.

Lightweight

Expanded PVC foam board is renowned for its exceptional lightweight properties, which make it incredibly easy to handle and transport without sacrificing strength or durability.

Despite being light, the foam PVC sheets maintain excellent rigidity and structural integrity, ensuring they hold their shape well even when bent or subjected to stress.

This balance of lightness and strength contributes to the material’s versatility across various thicknesses and sizes, enabling its use in applications ranging from photo mounting and signage to model making and wood replacement projects.

The reduced weight also lowers shipping costs and simplifies installation, making expanded PVC foam board a cost-effective and practical choice for many industries.

Moisture Resistant

One of the standout features of expanded PVC foam board is its excellent moisture resistance.

Thanks to its closed-cell foam structure, PVC foam sheets effectively prevent water absorption, making them ideal for use in damp or humid environments.

This moisture resistance not only enhances the material’s durability but also prevents issues such as warping, swelling, or degradation over time.

Impact Resistant

Expanded PVC foam board is highly impact resistant, making it an excellent choice for applications that demand durability and toughness.

Its closed-cell foam structure absorbs shocks and resists dents and scratches, ensuring that the material maintains its integrity even under heavy use or accidental impacts.

This resilience makes PVC foam sheets ideal for environments such as trade shows, exhibit booths, and signage where frequent handling and transportation occur.

Manufacturing Process Of Foam PVC Sheets

The manufacturing process of foam PVC sheets involves a sophisticated extrusion technique combined with precise foaming agents to achieve the desired closed-cell structure.

Initially, high-quality PVC resin is melted and mixed with carefully selected foaming agents and additives that enhance properties such as UV resistance, fire retardancy, and durability.

This mixture is then extruded through specialized dies to form uniform sheets with consistent thickness and density.

As the material cools, the foaming agents create a lightweight, rigid foam core that provides excellent strength-to-weight ratio and impact resistance.

Throughout production, stringent quality control measures ensure that each foam PVC sheet meets exact standards for smooth surface finish, dimensional stability, and mechanical performance.

Popular Applications For PVC Foam Sheets

The versatility of PVC foam sheets makes them an excellent choice for a wide range of applications.

Marine Uses

Marine-grade PVC foam sheets are specially engineered to endure the demanding conditions of marine environments.

Additionally, marine-grade PVC foam boards feature enhanced UV protection and weatherability, ensuring long-lasting durability even under prolonged sun exposure and harsh outdoor elements.

They are easy to fabricate and can be cut, drilled, and shaped using ordinary tools, making them a practical and reliable choice for both professional boat builders and DIY enthusiasts.

This versatility also allows them to be bonded securely with adhesives and fasteners, providing a durable wood replacement material that withstands moisture, salt, and wear in marine settings.

Displays

PVC foam sheets are an excellent choice for a wide variety of display applications due to their lightweight yet durable nature.

Their smooth surface and matte finish provide an ideal base for high-quality screen printing and vinyl lettering, ensuring that signs and graphics appear sharp and professional.

Whether used for point-of-purchase displays, exhibit booths, trade shows, or outdoor signage, expanded PVC foam boards offer outstanding durability, moisture resistance, and impact resistance.

These features, combined with easy access to a wide range of colors and environmentally friendly manufacturing processes, make foam PVC sheets an ideal choice for both indoor and outdoor applications.

Model Making

PVC foam sheets are an excellent material choice for model making due to their lightweight yet rigid nature.

These sheets can be easily sawed, drilled, and shaped using standard tools, allowing hobbyists and professionals to create detailed and precise models with ease.

The smooth surface and matte finish provide an ideal base for painting, laminating, or applying vinyl lettering, ensuring a professional appearance for architectural models, prototypes, and hobby crafts.

Interior Design

PVC foam sheets are increasingly popular in interior design due to their lightweight, durable, and versatile nature.

Their smooth surface with a matte finish makes them suitable for various decorative applications, including wall panels, ceiling tiles, and custom cabinetry.

These sheets are easy to fabricate with ordinary tools, allowing designers to create intricate shapes and patterns that enhance aesthetic appeal.

Environmental Benefits Of PVC Foam Sheets

PVC foam sheets provide numerous environmental advantages that contribute to sustainable and eco-friendly practices.

These sheets are manufactured using non-toxic materials and additives, ensuring minimal environmental impact during production and use.

Their closed-cell structure not only offers excellent durability and moisture resistance but also allows for recyclability, reducing waste and promoting resource conservation.

Additionally, PVC foam sheets feature inherent flame-retardant properties with low smoke emission, enhancing safety while minimizing harmful environmental effects.

Many PVC foam sheets are free from harmful substances such as lead and cadmium, supporting green initiatives by offering a durable, recyclable, and safe material option ideal for environmentally conscious projects.

How To Choose The Right PVC Foam Sheet?

Selecting the right PVC foam sheet involves considering several factors, including the specific requirements of your project and feedback from customers who have used these materials in similar applications.

Surface preparation is crucial for effective bonding; cleaning the surface with isopropyl alcohol ensures better adhesion. This step is essential to achieve a strong bonded bond with adhesives or other materials.

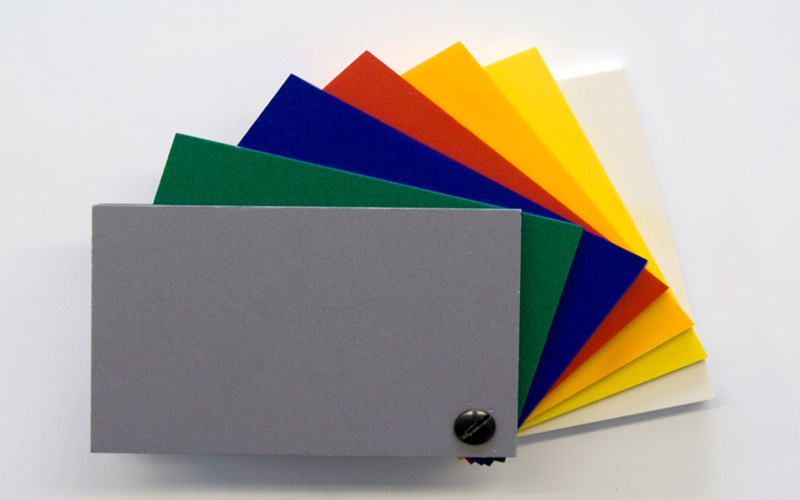

Colored PVC foam sheets are available in various hues, including gray, offering better visual appeal for projects that require specific aesthetics.

Many customers recommend testing a sample before large-scale cutting or gluing to ensure compatibility and achieve the desired results.

Summary

In conclusion, PVC foam sheets are a versatile and sustainable material with a wide range of applications.

From marine and outdoor uses to signage, display solutions, and model making, their unique properties make them an indispensable choice for various industries.

Their environmental benefits, including fire retardancy, recyclability, and eco-friendly production, further enhance their appeal.

By choosing PVC foam sheets, consumers can contribute to a healthier and more sustainable environment.

Whether you’re a professional or a DIY enthusiast, understanding the key features, manufacturing process, and applications of PVC foam sheets will help you make informed decisions for your projects.