Polytetrafluoroethylene, commonly known as PTFE, is a versatile and highly sought-after material prized for its unique properties such as excellent thermal resistance, low coefficient of friction, and outstanding electrical insulation properties.

This comprehensive guide will help you understand the key features, benefits, and common uses of PTFE sheets, along with practical tips on how to select, order, and work with this remarkable material.

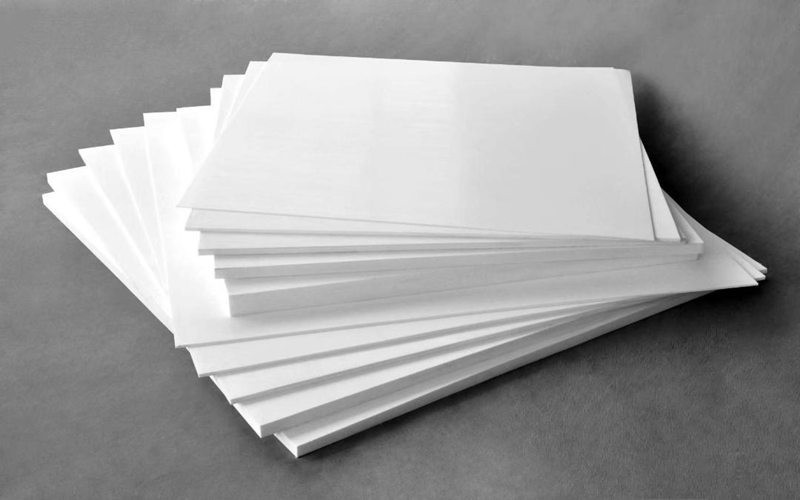

What Are PTFE Sheets?

PTFE sheets are flat, solid materials made from polytetrafluoroethylene, a synthetic fluoropolymer known for its exceptional chemical resistance, non-stick surface, and high thermal stability.

These sheets are available in various thicknesses and sizes, making them easy to cut and shape for different industrial and commercial applications.

Additionally, PTFE sheets are offered in both virgin and filled grades, allowing users to select the best option based on their specific needs.

Whether you need a thick or thin sheet, PTFE material provides reliable protection and durability, making it a popular choice across many industries.

Key Properties Of PTFE Sheets

PTFE sheets possess several outstanding properties that make them ideal for a wide range of applications.

Excellent Thermal Resistance

PTFE sheets are renowned for their excellent thermal resistance, capable of withstanding continuous service temperatures up to 500°F (260°C) without degradation.

This high-temperature tolerance makes PTFE an ideal material for applications in harsh thermal environments, such as chemical processing, electrical insulation, and gasket manufacturing.

Low Coefficient Of Friction

One of the standout features of PTFE sheets is their exceptionally low coefficient of friction.

This means that surfaces made from or coated with PTFE experience minimal resistance when sliding against other materials.

This property is crucial in applications where reducing wear and tear is essential, such as in bearings, seals, and gaskets.

The low friction not only extends the lifespan of mechanical parts but also improves efficiency by reducing energy loss due to friction.

Outstanding Electrical Insulation Properties

PTFE sheets are highly valued for their outstanding electrical insulation properties, making them a preferred choice in many electrical and electronic applications.

This material offers excellent dielectric strength, effectively preventing electrical currents from passing through, which helps protect sensitive components from damage.

Additionally, PTFE’s resistance to high voltages and its ability to maintain insulating performance even at elevated temperatures ensure reliable operation in demanding environments.

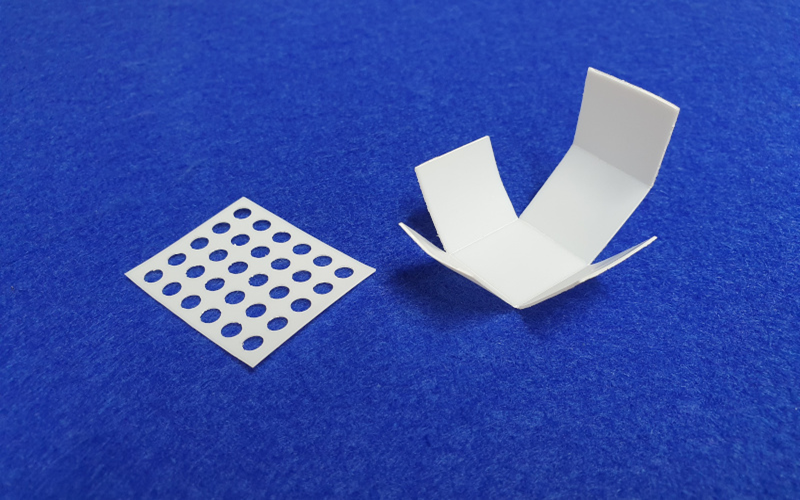

Easy To Fabricate

PTFE sheets are highly regarded for their ease of fabrication, making them a practical choice for many industries.

They can be easily cut, drilled, stamped, and machined into precise sizes and complex shapes without requiring specialized tools or equipment.

This flexibility allows manufacturers to quickly produce custom parts such as gaskets, seals, and liners tailored to specific applications.

Common Thicknesses Of PTFE Sheet

PTFE sheets are available in a variety of thicknesses to suit different applications and requirements. Here are some of the most common thickness options:

Thin Sheets (0.005 To 0.020)

These ultra-thin PTFE sheets are highly valued for applications requiring exceptional flexibility, easy cutting, and precise electrical insulation.

Commonly used as electrical insulation films and protective liners, these thin sheets offer excellent chemical resistance and durability despite their minimal thickness, making them ideal for delicate and intricate industrial uses.

Standard Thickness (0.030 To 0. 1 4)

PTFE sheets with a standard thickness ranging from 0.030 to 0.14 inches are among the most commonly used sizes in various industrial and commercial applications.

This thickness range offers an excellent balance of strength, flexibility, and ease of fabrication, making these sheets ideal for producing reliable gaskets, seals, and wear pads.

The material’s durability at this thickness allows it to withstand moderate mechanical stress and chemical exposure while maintaining its low coefficient of friction and outstanding electrical insulation properties.

Thick Sheets (0.250 And Above)

Thicker PTFE sheets provide enhanced mechanical strength and durability, making them ideal for heavy-duty industrial applications such as stamping, machining, and structural components.

These thick sheets offer excellent resistance to wear, impact, and chemical exposure, ensuring long-lasting performance even in the most demanding environments.

Common Applications Of PTFE Sheets

PTFE sheets are widely used across various industries due to their unique combination of properties.

Chemical Processing

PTFE sheets are extensively used in chemical processing industries due to their exceptional resistance to a wide range of corrosive chemicals and solvents.

These sheets serve as reliable linings for tanks, pipes, and vessels, effectively protecting expensive equipment from damage caused by aggressive substances.

Electrical Insulation

PTFE sheets are highly regarded for their superior electrical insulation capabilities, making them indispensable in many electrical and electronic applications.

Their excellent dielectric strength ensures that they effectively prevent electrical currents from passing through, providing reliable protection for sensitive components.

PTFE’s ability to maintain insulating properties even at elevated temperatures up to 500°F (260°C) makes it ideal for use in high-performance wiring, cables, circuit boards, and other critical electrical equipment.

Gaskets And Seals

PTFE sheets are widely used in the production of gaskets and seals due to their exceptional chemical resistance, low coefficient of friction, and excellent thermal stability.

These properties ensure that gaskets and seals made from PTFE can withstand harsh environments, including exposure to aggressive chemicals and high temperatures, without degrading or losing effectiveness.

Mechanical Components

PTFE sheets are widely used in mechanical components such as bearings, wear pads, and liners due to their exceptional wear resistance and low coefficient of friction.

These properties help reduce friction and wear between moving parts, extending the life of machinery and improving operational efficiency.

Medical Applications

PTFE sheets are highly valued in the medical field due to their excellent biocompatibility, chemical inertness, and resistance to sterilization processes.

These properties make PTFE an ideal material for manufacturing medical devices, implants, and surgical instruments.

PTFE sheets are used in applications such as vascular grafts, catheter liners, and wound dressings, where their non-reactive nature helps prevent adverse bodily reactions.

How To Choose The PTFE Sheet?

Choosing the right PTFE sheet for your application involves considering several important factors to ensure optimal performance and cost-effectiveness.

First, evaluate the required thickness based on the mechanical strength and flexibility needed; thin sheets are ideal for electrical insulation and delicate tasks, while thicker sheets suit heavy-duty applications like stamping and machining.

Next, consider whether you need virgin or filled PTFE—virgin offers superior chemical resistance and purity, whereas filled grades provide enhanced wear resistance and mechanical strength.

It’s also essential to check the sheet’s size and availability in stock to meet your project timeline. Additionally, review the list price and compare it across different suppliers to get the best value.

Finally, ensure the supplier offers secure ordering through their website, with clear policies on returns and customer support via email or phone.

By carefully assessing these factors, you can select the perfect PTFE sheet that meets your technical requirements and budget.

Conclusion

In summary, PTFE sheets, often referred to as Teflon sheets, offer a unique combination of excellent thermal resistance, low coefficient of friction, and outstanding electrical insulation properties, making them indispensable across a wide range of industries.

When selecting a PTFE sheet, consider factors such as thickness, grade, and application requirements to ensure optimal results.

These high-quality items are commonly sold in various sizes and thicknesses to meet diverse needs.

Ordering is simple and secure—just click to add your desired PTFE sheets to your cart on reputable websites that prioritize your security throughout the purchasing process.

By understanding these key aspects, you can confidently choose the right PTFE sheet to meet your specific needs and enhance the efficiency and longevity of your projects.

Frequently Asked Questions

What Is A PTFE Sheet?

A PTFE sheet is a flat, solid material made from polytetrafluoroethylene, known for its excellent chemical resistance, low friction, and high thermal stability.

What Factors Influence The List Price Of PTFE Sheets?

The list price of PTFE sheets is influenced by factors such as thickness, size, grade (virgin or filled), and supplier pricing policies.

Can PTFE Sheets Be Easily Cut Or Fabricated?

Yes, PTFE sheets are easy to cut, drill, stamp, and machine without needing specialized tools, which makes them highly versatile for custom applications.

What Industries Commonly Use PTFE Sheets?

PTFE sheets are widely used in chemical processing, electrical insulation, gasket and seal manufacturing, mechanical components, and medical applications due to their unique properties.

How Do I Choose The Right PTFE Sheet For My Application?

Consider factors such as required thickness, whether virgin or filled grade is needed, size availability, price, and supplier reliability to select the best PTFE sheet for your specific needs.