Polystyrene plastic sheets, derived from the versatile polymer polystyrene, are widely valued for their lightweight, rigid, and cost-effective nature.

These sheets exhibit excellent dimensional stability and durability, making them suitable for a broad range of applications.

This article explores the key properties of polystyrene plastic sheets, their diverse applications, and their significance in modern manufacturing, while also addressing their benefits, price considerations, and challenges in a rapidly evolving, sustainability-focused world.

What Is Polystyrene Plastic Sheet?

A polystyrene plastic sheet is a versatile plastic material made from the polymer polystyrene, widely used in various industries due to its excellent dimensional stability and durability.

This sheet material is lightweight yet rigid, making it ideal for applications requiring strength without added bulk.

Polystyrene sheets can be easily cut, fabricated, and assembled, offering great flexibility for manufacturers and hobbyists alike.

Available in different thicknesses, these sheets cater to diverse needs, from thin films used in packaging to thicker panels for signage and prototypes.

The material’s low cost and ability to be painted or printed on further enhance its appeal, making polystyrene plastic sheets a popular choice for everyday products and specialized applications.

Types Of Polystyrene Sheet

Polystyrene plastic sheets are available in various forms, each tailored to specific applications due to their distinct properties.

General Purpose Polystyrene (GPPS) Sheet

GPPS sheets are characterized by their high clarity and glass-like transparency, making them ideal for applications requiring visual appeal, such as signage, display cases, and point-of-sale displays.

They are rigid but relatively brittle, suitable for non-impact applications.

High Impact Polystyrene (HIPS) Sheet

HIPS sheets are modified with rubber additives to enhance toughness and impact resistance.

This makes them less brittle than GPPS and ideal for durable applications like packaging trays, protective covers, and consumer product casings where flexibility and strength are needed.

Expanded Polystyrene (EPS) Sheet

EPS sheets, commonly known as foam boards, are lightweight and provide excellent thermal insulation.

They are widely used in construction for insulation panels and in packaging for cushioning fragile items, leveraging their low density and shock-absorbing properties.

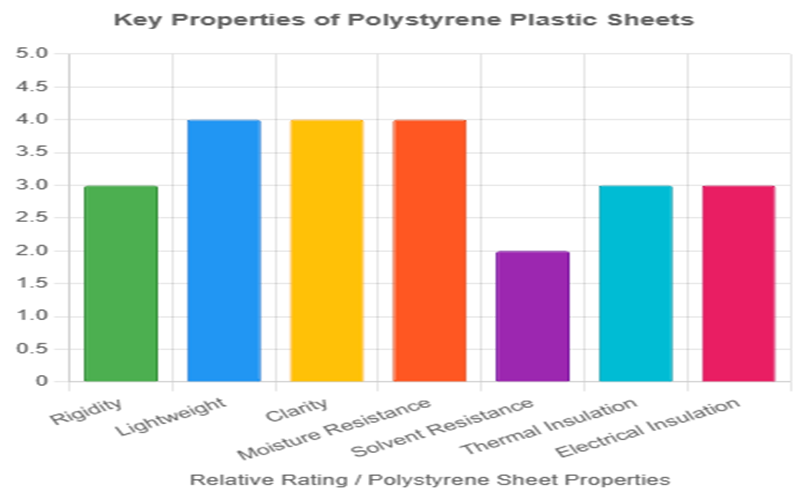

Characteristics Of Polystyrene Plastic Sheet

Polystyrene plastic sheets are valued for their unique combination of properties that make them suitable for a wide range of applications.

Physical Properties

Polystyrene sheets, especially general-purpose polystyrene (GPPS), are rigid and offer excellent dimensional and structural stability, ideal for signage and displays.

They are lightweight, with a density around 1.05 g/cm³, making them easy to handle and cost-effective.

GPPS sheets provide glass-like clarity, perfect for aesthetic uses like protective covers and point-of-sale displays.

They also maintain good low temperature properties, ensuring strength and performance in cooler environments.

Chemical Properties

Polystyrene sheets demonstrate good resistance to moisture, making them suitable for packaging food or other water-sensitive products.

They also exhibit good dimensional stability when exposed to varying humidity levels, ensuring consistent performance in diverse environments.

However, they have limitations when exposed to certain solvents, such as aromatic hydrocarbons and ketones, which can cause degradation, swelling, or cracking.

This chemical sensitivity requires careful consideration in environments where solvent exposure is likely, and appropriate protective measures should be taken to preserve the material’s integrity.

Thermal Insulation

Polystyrene sheets provide effective thermal insulation, especially in their expanded foam forms commonly used in construction and packaging.

Their low thermal conductivity helps reduce heat transfer, making them ideal for insulating walls, roofs, and refrigerated containers.

This insulation capability contributes to energy efficiency by maintaining temperature stability in buildings and products, thereby lowering heating and cooling costs.

Electrical Insulation Characteristics

Polystyrene plastic sheets also exhibit excellent electrical insulation properties, characterized by their high dielectric strength and low electrical conductivity.

These features make them an ideal choice for insulating components in electrical devices, protective casings, and other applications requiring reliable electrical resistance.

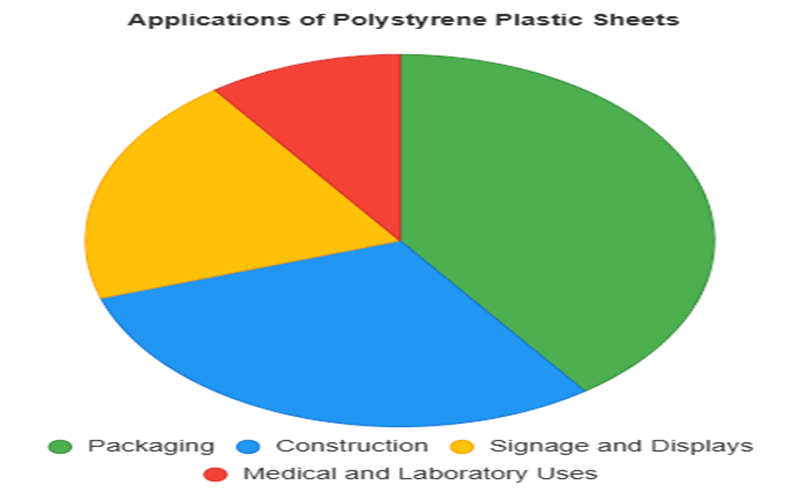

Applications Of Polystyrene Plastic Sheet

Polystyrene plastic sheets are employed across a diverse range of industries due to their versatility, clarity, and cost-effectiveness.

Packaging

Polystyrene sheets are widely used in packaging for food trays and protective packaging due to their lightweight, excellent dimensional stability, and durability.

They are easily molded into various shapes, supporting printing and silk screening for attractive branding, all at a low cost and with easy fabrication.

Construction

In construction, expanded polystyrene foam sheets are popular insulation panels due to their excellent thermal insulation and low thermal conductivity.

They enhance energy efficiency by stabilizing building temperatures, lowering heating and cooling costs.

Their lightweight and durable nature also makes them easy to install and long-lasting in building projects.

Display

General-purpose polystyrene sheets are ideal for signage and displays due to their clarity, rigidity, and excellent dimensional stability.

They are commonly used in advertising boards, retail signage, and exhibition panels, supporting high-quality printing and silk screening.

Their durability and impact resistance help maintain structural integrity and appearance in busy environments.

Medical Use

Polystyrene sheets are widely used in medical and lab settings for items like petri dishes and disposable trays.

Their chemical inertness, dimensional stability, and sterilization tolerance ensure hygiene and reliability. Additionally, their low cost and easy fabrication support efficient mass production of medical disposables.

Safety And Environmental Impact

Polystyrene sheets are non-toxic and odorless, making them safe for a wide variety of applications, including food packaging and medical uses.

Styrene plastic is generally considered safe for consumers when encountered in small quantities, such as those found in food contact materials or ambient air.

Additionally, this material is fully recyclable, allowing it to be melted down and repurposed, which helps minimize waste during product lifecycle and demolition phases.

However, the recycling process for polystyrene can be costly and technically complex, resulting in relatively low recycling rates globally.

To address environmental concerns, selecting a supplier that prioritizes sustainability and offers eco-friendly polystyrene options is highly recommended.

Summary

Polystyrene plastic sheets combine durability, flexibility, and cost-effectiveness, making them an outstanding material choice across multiple industries.

Their excellent dimensional stability, low water absorption, and superior electrical insulation properties ensure reliable performance in diverse environments and applications.

These versatile sheets are widely used in packaging, construction, medical, automotive, and display sectors, demonstrating their broad applicability.

Key benefits include ease of fabrication and assembly, affordability, chemical resistance, and the ability to protect products effectively.

As environmental concerns grow, focusing on the responsible purchase, use, and recycling of polystyrene sheets is crucial.

By adopting sustainable practices and choosing eco-friendly options, industries can continue to leverage the advantages of this remarkable material while minimizing its environmental footprint for a greener future.

Frequently Asked Questions

What Is Poly Styrene Plastic Made Of?

Polystyrene is composed of long-chain hydrocarbons formed from styrene monomers, represented by the chemical formula C8H8.

What Are Some Common Applications Of Polystyrene Plastic Sheet?

Polystyrene plastic sheets are commonly utilized in packaging, construction, electronics, medical applications, arts and crafts, and signage.

Are Polystyrene Sheets Safe To Use?

Polystyrene sheets are safe for use as they are non-toxic and odorless, suitable for various applications. Always ensure proper handling and application to maximize safety.

Can Polystyrene Be Recycled?

Polystyrene can be recycled, designated by recycling code 6, but the process is often expensive and complex, resulting in low recycling rates.

What Makes High Impact Polystyrene (HIPS) Special?

High Impact Polystyrene (HIPS) is special due to its exceptional impact resistance, versatility, and cost-efficiency, combined with properties such as flatness, low moisture absorption, and non-toxicity.