Plastic sheet manufacturing is a cornerstone of modern industrial processes, providing versatile, durable, and cost-effective materials for a wide range of applications.

From construction and packaging to automotive and medical sectors, plastic sheets are integral to countless products due to their adaptability and performance.

This article explores the materials, manufacturing methods, and market dynamics driving the plastic sheet industry, while highlighting emerging trends and sustainability efforts shaping its future.

Materials Used In Plastic Sheet Manufacturing

Plastic sheet manufacturing utilizes a broad range of plastic materials, each chosen for specific properties that suit various applications and environments.

Polyvinyl Chloride (PVC)

Known for its chemical resistance and durability, PVC sheets are widely used in construction, medical, and packaging industries.

They offer excellent impact resistance and long term durability, making them ideal for protective barriers and machine guards.

Acrylic

Valued for their optical clarity and aesthetic appeal, acrylic sheets are popular in retail displays and signage.

They can be produced in custom colors and various sheet sizes, offering versatility for design and fabrication.

Polycarbonate

This material provides exceptional impact resistance and high durability, suitable for harsh environments and applications requiring strength and safety.

Polyethylene

Polyethylene often used for packaging and containers, polyethylene sheets are lightweight yet durable, with good chemical resistance.

In summary, these materials can be supplied as extruded plastic sheets, rods, and films, and are compatible with various plastic fabrication techniques such as injection molding, blow molding, vacuum forming, CNC machining, laser cutting, and CNC routing.

Selecting the right type of plastic material is crucial to achieving the desired balance of durability, impact resistance, chemical resistance, and aesthetic qualities in the final plastic products.

Plastic Sheet Fabrication Methods

Plastic sheet fabrication encompasses a variety of advanced techniques, each designed to produce sheets with tailored properties for specific applications.

Key methods, including extrusion, thermoforming, CNC machining, blow molding, and injection molding, are optimized for materials like ABS, PVC, polycarbonate, polyethylene, and acrylic, ensuring high efficiency, precision, and quality across diverse industries.

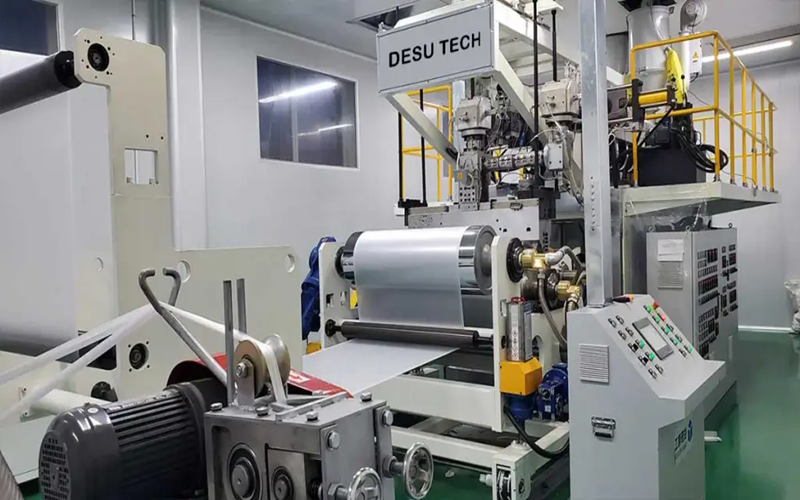

Extrusion

In this widely used process, molten plastic is forced through a die to form continuous sheets of uniform thickness.

It is highly efficient for producing ABS, PVC, and polyethylene sheets, which are commonly used in packaging and construction.

Extrusion allows for high-volume production and can incorporate additives for enhanced properties like UV resistance or flame retardancy.

CNC Machining

CNC (Computer Numerical Control) machining uses computer-controlled tools to cut, drill, or shape plastic sheets with exceptional precision.

Suitable for materials like polycarbonate, acrylic, and ABS, it is ideal for creating custom components, prototypes, or intricate designs for signage, medical devices, and industrial applications. CNC machining offers high accuracy and repeatability, enabling complex geometries that other methods may not achieve.

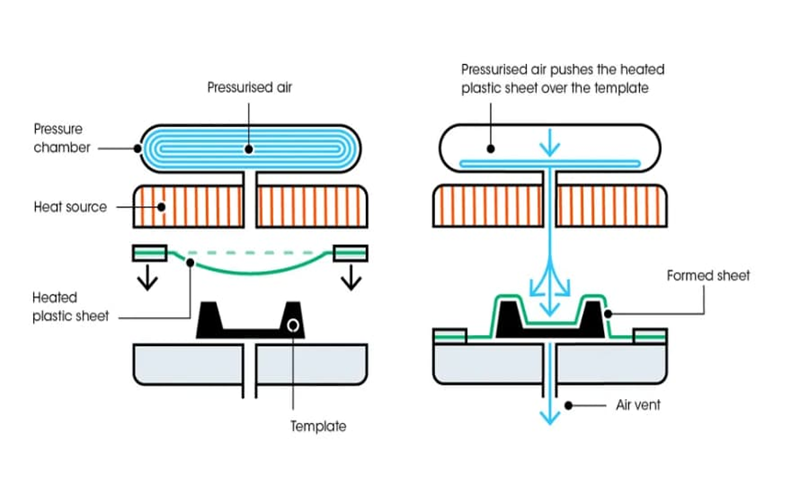

Thermoforming

In thermoforming, plastic sheets are heated until pliable and then shaped into complex forms using molds, vacuum, or pressure.

This technique is commonly applied to ABS and polycarbonate for automotive components and consumer goods.

Thermoforming excels in producing intricate, lightweight parts with high precision, making it a preferred method for customized designs.

Blow Molding

In blow molding, heated plastic sheets or preforms are inflated within a mold to create hollow or contoured shapes.

While typically used for polyethylene and PVC, this method is applied in packaging and construction. Blow molding is efficient for producing seamless, lightweight products with consistent wall thickness, catering to both functional and aesthetic needs.

Injection Molding

Injection molding involves injecting molten plastic into a mold to form precise, detailed sheet components or parts.

Commonly used for ABS, polycarbonate, and acrylic, it is ideal for high-volume production of small, intricate items like automotive trim, consumer electronics casings, and medical device components.

This method ensures high precision and repeatability, making it suitable for complex, high-performance applications.

Applications Of Plastic Sheet

Plastic sheets, as highly adaptable plastic products, are essential across numerous industries due to their customizable properties, durability, and cost-effectiveness.

Materials such as ABS, PVC, polycarbonate, polyethylene, and acrylic are meticulously engineered to meet specific functional and aesthetic needs in construction, packaging, automotive, and other specialized sectors, driving innovation and efficiency in modern manufacturing.

Construction

Plastic sheets are indispensable in modern construction, offering robust solutions for diverse applications.

ABS and PVC sheets are extensively used for pipes and cladding, providing exceptional corrosion resistance and durability for plumbing systems and exterior finishes.

Polycarbonate and acrylic sheets are favored for glazing applications, such as windows and skylights, as well as decorative panels, delivering transparency, high strength, and resistance to harsh weather conditions.

Polyethylene sheets are employed as geomembranes, ensuring effective waterproofing and structural stability in foundations, landscaping, and infrastructure projects.

Packaging

In the packaging sector, plastic sheets provide critical solutions for safety, durability, and versatility.

Polyethylene sheets are widely used for food and industrial wraps, offering flexibility, moisture resistance, and cost-effectiveness for secure packaging.

PVC sheets are ideal for medical packaging, ensuring sterility and chemical resistance for sensitive products like pharmaceuticals and medical supplies.

ABS sheets are utilized for durable containers, providing robust protection for heavy or fragile goods during transportation and storage, enhancing product integrity across supply chains.

Automotive

Plastic sheets are vital in automotive manufacturing, balancing functionality with aesthetic appeal.

ABS sheets are employed for interior panels and dashboards, leveraging their toughness and ease of molding to create intricate, durable designs.

Polycarbonate sheets are used for headlight covers and protective shields, offering superior impact resistance and optical clarity for enhanced safety and visibility.

Acrylic sheets are applied in aesthetic trims, providing vibrant, UV-resistant finishes that elevate vehicle aesthetics while maintaining long-term durability.

Other Sectors

Plastic sheets extend their utility beyond core industries, supporting a wide range of specialized applications.

Acrylic and polycarbonate sheets are dominant in signage, offering clarity, durability, and weather resistance for vibrant advertising boards and illuminated displays.

PVC sheets are crucial in medical devices, such as tubing and sterile enclosures, due to their biocompatibility and chemical stability, ensuring safety in healthcare settings.

ABS sheets are prevalent in consumer goods, including appliances and toys , where their high impact resistance ensures longevity and reliability under rigorous use.

Plastic Sheet Manufacturing Market Trends

The plastic sheet manufacturing market is rapidly evolving, driven by innovations in materials, sustainability initiatives, and advanced production technologies that meet the growing demands of diverse industries.

High-Performance Sheets

There is a growing demand for high-performance plastic sheets like polycarbonate and engineered plastics, prized for their lightweight nature, exceptional impact resistance, chemical resistance, and long-term durability.

These materials are increasingly used in automotive, aerospace, medical, and electronics industries, where reliable plastic parts are essential.

Eco-Friendly Materials

The plastics industry is embracing sustainability with the rising adoption of recycled plastics, biodegradable polymers such as PLA, and other eco-friendly materials.

These innovations are transforming packaging, construction, and consumer goods sectors by reducing environmental impact while maintaining the durability and quality expected from standard items.

Manufacturers are investing in chemical resistant and durable plastic materials that align with evolving environmental regulations and customer demands.

Smart Manufacturing

Smart manufacturing technologies, including Industry 4.0 advancements like artificial intelligence (AI), the Internet of Things (IoT), and automation, are reshaping plastic sheet manufacturing.

These technologies enhance production efficiency, reduce waste, improve quality control, and shorten lead times, enabling manufacturers and local branches to offer exceptional service and customized solutions that meet the highest standards in the plastics industry.

By integrating these innovations, companies can optimize plastic fabrication processes, improve stock management, and deliver superior plastic products tailored to specific industry requirements.

Conclusion

Plastic sheet manufacturing plays a vital role across many industries by providing versatile, durable, and cost-effective materials.

With a broad range of common materials like PVC, acrylic, and polycarbonate, and advanced manufacturing processes such as extrusion, injection molding, and thermoforming, the plastics industry continues to innovate and meet diverse market needs.

The future of plastics manufacturing is poised for transformation, driven by sustainability and technological innovation.