Plastic polycarbonate sheets combine toughness, high transparency and excellent impact resistance to ensure durability while meeting the need for clear visibility, making them ideal for projects that demand both endurance and visibility.

Polycarbonate is one of many types of plastics, and polycarbonate sheets themselves are available in many types, each designed for specific applications such as greenhouses, security glazing, and safety shields.

Whether it’s a machine guard that needs to withstand external impacts, a greenhouse that needs to let in light, or security glazing where safety and transparency are both important, plastic polycarbonate sheets are up to the task.

In this article, we’ll take a closer look at the properties of this material, its wide range of applications, well-known brands, and practical maintenance tips to provide a comprehensive analysis of plastic polycarbonate sheets.

Introduction To Polycarbonate

Polycarbonate is a highly versatile thermoplastic material celebrated for its remarkable strength and durability.

Unlike traditional glass, polycarbonate sheets are approximately 200 times stronger and weigh only half as much, making them an ideal choice for projects where both safety and ease of installation are priorities.

This unique combination of properties allows polycarbonate to excel in many applications, from construction and security barriers to industrial machine guards and protective glazing.

One of the standout features of polycarbonate is its resistance to UV rays, which helps maintain its clarity and structural integrity even after prolonged outdoor exposure. This makes polycarbonate sheets especially valuable in environments where durability and weather resistance are essential.

Thanks to its lightweight nature and exceptional impact resistance, polycarbonate is widely used in construction, industrial applications, and any setting where the risk of breakage or damage is a concern.

Its adaptability and robust performance have made polycarbonate a preferred material for architects, engineers, and manufacturers seeking reliable solutions for demanding projects.

Types Of Polycarbonate Panels

Polycarbonate panels are available in a variety of types, each tailored to specific requirements and applications.

Clear polycarbonate sheets are prized for their outstanding light transmission, making them a popular choice for greenhouses, skylights, and any project where natural lighting is a priority.

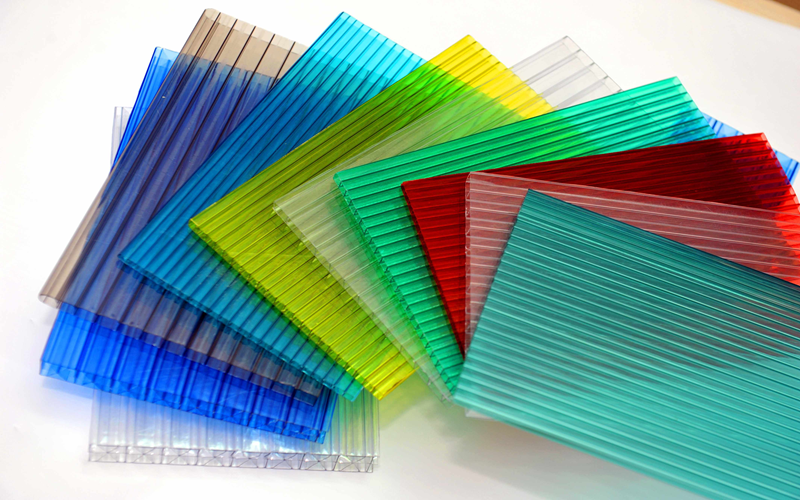

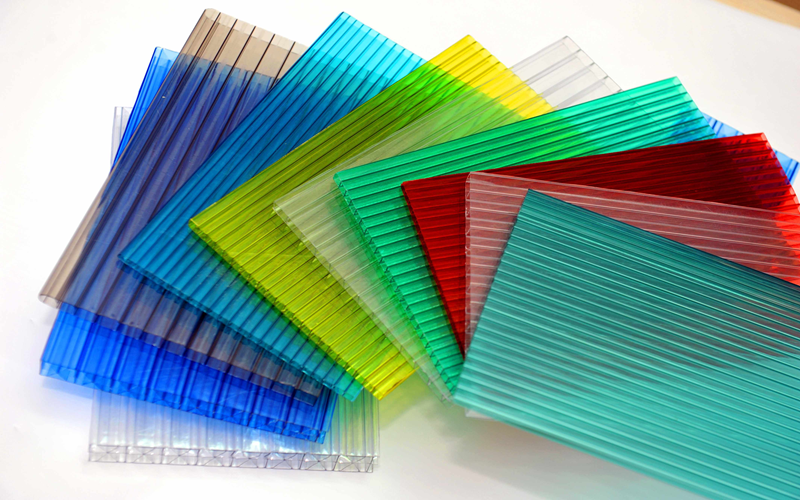

For situations where controlling light and heat is important, tinted polycarbonate sheets offer effective UV protection and reduced light transmission, making them suitable for roofing, awnings, and sunrooms.

Opaque polycarbonate sheets are commonly used in signage, privacy panels, and applications where light transmission is not needed but durability and impact resistance are still essential.

For high-traffic or exterior environments, abrasion-resistant polycarbonate panels—such as Monogal AR—provide enhanced protection against scratches and wear, ensuring a longer lifespan even under frequent use.

Polycarbonate panels are manufactured in a range of thicknesses to accommodate different structural and performance needs. They can be easily cut to size, allowing for precise customization in construction, commercial, and industrial projects.

This versatility, combined with their durability and resistance to environmental factors, makes polycarbonate panels a smart choice for a wide array of applications, from skylights and barriers to machine guards and architectural features.

Key Properties Of Polycarbonate Plastic Sheets

Polycarbonate plastic sheets are renowned for their high Impact performance and optical clarity, making them ideal for projects requiring both endurance and visibility. These properties make them perfect for protective covers for precision instruments and high-end aquariums.

Their exceptional Impact performance renders polycarbonate sheets excellent for sports safety equipment such as helmets, ski goggles, and face masks, significantly reducing injury risk while ensuring clear vision. This versatility underscores their importance in high-impact scenarios and helps overcome barriers.

Polycarbonate plastic sheets offer exceptional clarity and excellent transparency, with a light transmission rate over 90%, ensuring well-lit spaces like greenhouses and exhibition halls with maximum visibility and natural light penetration. Additionally, they resist brittleness from prolonged UV exposure, maintaining clarity over time, which is crucial for outdoor applications. Polycarbonate sheets are also highly resistant to break, even under significant impact, making them a durable choice for demanding environments.

Surface treatments enhance the endurance of polycarbonate plastic sheets, improving scratch resistance and UV stability against UV rays, thus extending the lifespan of products like outdoor billboards, awnings, and automotive lamp covers. They also maintain high thermal stability, reliably performing in temperatures from -40°C to 120°C, making them suitable for extreme climates.

Applications Of Polycarbonate Sheets

Polycarbonate sheets are used in a variety of commercial industries because of their high impact strength, excellent optical clarity, high tensile strength and endurance. Their applications span agriculture, automotive, construction, electronics, medical, and security sectors. Polycarbonate sheets are also widely used as dividers in offices, public spaces, and industrial environments due to their impact resistance and transparency.

In safety equipment, polycarbonate sheets provide essential protection with transparency in goggles, helmets, and bulletproof glass used in banks and security settings. The automotive industry benefits from their lightweight yet robust nature in headlight covers and interior components, while the medical field employs them for durable, sterilizable devices like incubators and surgical tools.

Polycarbonate’s superior light transmission makes it ideal for lighting fixtures and diffusers, offering uniform light distribution. Their endurance, reusability, and resistance to damage enhance consumer goods such as water bottles and food containers.

Thanks to their flexibility and impact performance—being 250 times stronger than glass—polycarbonate panels are also favored for bullet-resistant glass, protective gear, exterior architecture, and greenhouses, demonstrating versatility across many applications.

Cleaning And Maintenance Tips Of Plastic Polycarbonate Sheets

Maintaining polycarbonate sheets is straightforward but requires attention to detail. Use warm water with a neutral detergent, such as mild dish soap, to ensure the sheets remain clean without causing damage.

Always use a soft cloth microfiber cloth for cleaning polycarbonate sheets. These cloths prevent scratches that rough rags or steel wool might cause.

Avoid pressure washers or scouring pads, as strong water jets can create uneven pressure, potentially leading to deformation or cracking, and the abrasive texture of scouring pads can scratch the sheet, damaging its smoothness and transparency.

Regular cleaning is crucial for maintaining polycarbonate sheets. Outdoor sheets should be cleaned every 3-6 months to prevent dust, bird droppings, and other deposits from forming stubborn stains. Indoor sheets can be cleaned every six months to a year.

Thoroughly cleaning the polycarbonate surface with soapy water before applying any glazing adhesive ensures strong and durable adhesion.

Comparing Polycarbonate With Other Materials

The impact performance of polycarbonate sheet far exceeds that of glass, with an impact strength of approximately 200 times that of glass. This significant advantage makes it the material of choice in high-security environments, where traditional glass is prone to shattering and poses a significant risk.

Polycarbonate sheets are often the right choice for high-security and safety-critical applications due to their superior properties.

Polycarbonate sheet is half the weight of glass, a lightweight advantage that simplifies handling and installation in a variety of applications. For example, in the construction of large skylights, the use of polycarbonate panels reduces the load on the supporting structure, making it less difficult to construct and saving on labor costs. Glass, by contrast, is heavier and more labor-intensive, and requires a higher load-bearing capacity for the support structure.

General Purpose Polycarbonate offers unmatched toughness, glass-like transparency and excellent UV stability make this polycarbonate ideal for glazing, machine guards and signage. Polycarbonate sheets are available in different grades, each designed for specific uses and performance requirements.

Abrasion Resistance, its enhanced surface hardness prevents scratches and damage, extending the life of displays and lenses. Polycarbonate (Lexan) plastic sheet is half the weight of glass and is often used in scenarios such as windows, machine guards, instrument covers and signage.

You can also specify the width, length, and quantity of polycarbonate sheeting you require to make covered walkways, POP displays, machine guards, skylights, storefronts, and so much more. Selecting the appropriate thickness is crucial, as it affects impact resistance, durability, and suitability for various applications.

Polycarbonate vs Acrylic

It is more flexible, allowing it to be shaped at room temperature into complex forms like arches or waves to meet diverse design needs.

It has heat resistance up to 240°F (approximately 115.6°C), maintaining stability in high-temperature environments where acrylic might deform.

These properties make polycarbonate sheets particularly effective in heat-demanding scenarios, such as protective covers near heat sources.

Polycarbonate vs Other Materials

Polycarbonate sheets offer exceptional impact resistance, lightweight nature, flexibility, and heat resistance. These qualities make them the superior choice for a wide range of industrial applications, including construction applications, safety equipment, and pliable machine guards.

The process of cutting, forming, and fabricating polycarbonate sheets allows for extensive customization, enhancing their suitability for a wide range of applications.

Well suited for various grades and uses, polycarbonate demonstrates versatility and reliability as noted by manufacturers, making it ideal for diverse project needs.

| Property | Polycarbonate Sheet | Glass |

|---|---|---|

| Impact Strength | ~200 times that of glass | Prone to shattering |

| Impact Resistance | Exceptional (250x glass in some cases) | Fragile, poses safety risk |

| Weight | Half the weight of glass | Heavier, labor-intensive |

| Ease of Handling/Installation | Simplifies construction, reduces labor costs | Requires higher load-bearing support |

| Application Suitability | Ideal for high-security (e.g., bulletproof glass), skylights, machine guards | Limited to low-impact scenarios |

| Toughness | Unmatched toughness (General Purpose) | Brittle |

| Transparency | Glass-like, excellent clarity | Good clarity, but fragile |

| UV Stability | Excellent, resists brittleness over time | Poor, degrades with UV exposure |

| Abrasion Resistance | Enhanced surface hardness, scratch-resistant | Susceptible to scratches |

| Common Uses | Windows, machine guards, instrument covers, signage, covered walkways, POP displays, storefronts | Traditional windows, decorative glass |

How To Choose The Right Polycarbonate Panels?

When it comes to polycarbonate plastic sheets, several brands stand out for their quality and performance. Lexan®, Tuffak®, and Makrolon® are among the most recognized names in the market, each offering unique advantages.

Lexan® is perhaps the most well-known brand, often synonymous with pc plastic sheets. Its products are highly regarded for their excellent Impact performance and stability, making them suitable for a wide range of industrial and consumer applications. Lexan® has set a high standard in the industry, reflecting its widespread adoption and influence.

Known for their ability to withstand impacts, they’re excellent for applications where security is a concern, such as in security glazing, machine guards and protective shields. Polycarbonate is also highly heat-resistant, with a high melting point and a low coefficient of thermal expansion.

Makrolon® offers a range of general-purpose polycarbonate plastic sheets in thicknesses from 0.060 inches to 0.500 inches, catering to diverse project requirements. Whether for lightweight or structural applications, Makrolon® provides flexible options.

These come in multiple colors and thicknesses, tailored to specific project needs. Whether transparent, blue, green, or ranging from 0.060 inches to more substantial specifications, these sheets match a project’s aesthetic and functional demands.

For expert advice, custom requirements, or further information about polycarbonate sheets, contact the supplier or manufacturer directly.

Summary

In summary, polycarbonate sheets offer a unique combination of high impact resistance, optical clarity, UV resistance, and thermal stability, making them suitable for a wide range of applications. They are used in industries such as agriculture, automotive, construction, electronics, medical, and security, demonstrating their versatility.

Polycarbonate sheets are available in various brands and types, each offering specific advantages. Their endurance and longevity, coupled with straightforward cleaning and maintenance, make them a cost-effective choice for long-term projects. When compared to other materials like glass and acrylic, polycarbonate stands out for its superior properties. Explore the world of polycarbonate sheets and discover how they can enhance your projects with their unmatched performance and reliability.

Frequently Asked Questions

What are the key properties of polycarbonate sheets?

Polycarbonate sheets possess high impact resistance, excellent optical clarity, UV resistance, and thermal stability, making them versatile for various applications. These properties ensure durability while maintaining transparency and protection from harmful rays.

In which industries are polycarbonate sheets commonly used?

Polycarbonate sheets are commonly used in agriculture, automotive, construction, electronics, medical, and security industries. Their versatility and endurance make them suitable for various applications across these sectors.

What are some popular brands of polycarbonate sheets?

Popular brands of polycarbonate sheets include Lexan®, Tuffak®, and Makrolon®. These brands are well-regarded for their quality and durability.

How long do polycarbonate sheets typically last?

Polycarbonate sheets typically last between 20 to 30 years, even under harsh conditions. This durability makes them a reliable choice for various applications.

How should polycarbonate sheets be cleaned and maintained?

To effectively clean and maintain polycarbonate sheets, utilize warm water mixed with a neutral detergent and a soft microfiber cloth, ensuring to avoid pressure washers and scouring pads to prevent damage.