PET (Polyethylene Terephthalate) plastic sheets have emerged as a standout material across diverse industries due to their remarkable combination of strength, clarity, and versatility.

Renowned for their lightweight nature, chemical resistance, and recyclability, PET sheets are a preferred choice for applications ranging from food packaging to medical equipment and construction.

This article explores why PET plastic sheets are an excellent candidate, highlighting their unique properties, wide-ranging applications, and contributions to sustainability, making them an ideal solution for modern material needs.

What Is Polyethylene Terephthalate (PET) Plastic Sheet?

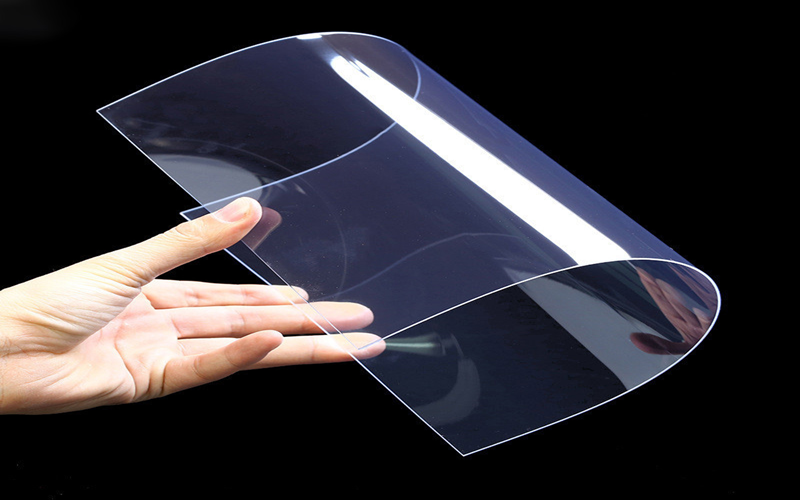

Polyethylene terephthalate plastic sheet is a type of polyester thermoplastic known for its excellent combination of strength, clarity, and chemical resistance.

PET is identified by the recycling code number 1 (♳), which is important for sorting and recycling processes.

Manufactured through a process that creates a mixture of crystalline and amorphous structures, PET sheets offer superior durability and flexibility, making them suitable for a wide range of applications.

Their lightweight yet strong properties allow them to serve as an ideal alternative to glass in many projects, providing excellent protection while maintaining transparency.

PET plastic sheets are widely used in industries such as packaging, construction, and medical equipment due to their ability to withstand wear, resist chemicals, and be easily fabricated.

Additionally, PET’s recyclability and environmental benefits make it an excellent candidate for sustainable manufacturing practices, further enhancing its appeal in today’s market.

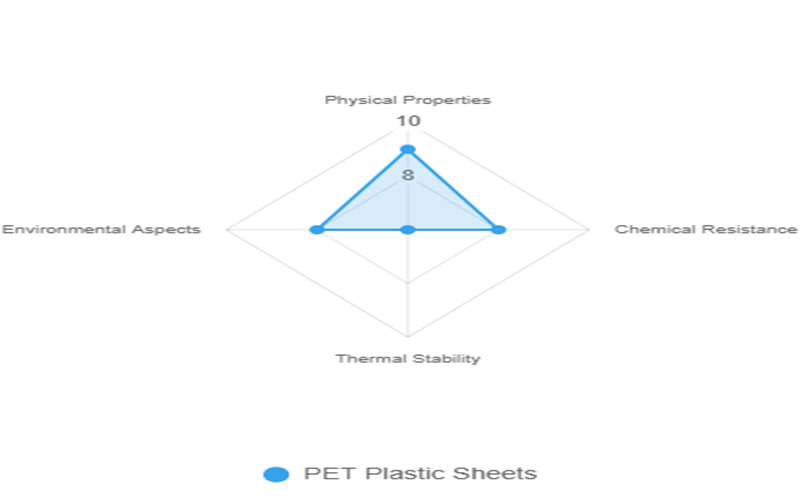

Properties Of PET Plastic Sheets

Physical Properties

PET (Polyethylene Terephthalate) plastic sheets are lightweight, easy to handle, and fabricate, making them suitable for diverse uses. PET sheets are resistant to break under normal handling and fabrication conditions, making them safer and more durable than some alternatives.

They offer exceptional transparency and clarity, comparable to glass, ideal for packaging, displays, and protective barriers where visibility matters.

PET sheets provide strong impact resistance and durability, ensuring long-lasting performance under demanding conditions. PET sheets can be easily cut with precision tools such as an et blade, ensuring clean edges and maintaining transparency.

Their dimensional stability and consistent thickness prevent warping, while a smooth surface enhances aesthetics and cleaning.

Additionally, PET resists UV light and moisture, making it reliable for outdoor and humid environments.

Available in various lengths and thicknesses, PET sheets can be customized to meet specific project needs.

Chemical Resistance

PET sheets exhibit strong resistance to many chemicals, including acids, bases, and alcohols, making them safe for direct contact with food and beverages.

This resistance ensures their use in containers, trays, and packaging that meet strict food safety standards.

Their chemical durability maintains clarity and structural integrity over time, essential for medical, industrial, and consumer products.

PET sheets also protect against environmental factors, safeguarding sensitive contents.

In industrial settings, they serve as protective barriers controlling access to equipment or products, ensuring security and preventing contamination.

Their robust properties make them ideal for server enclosures or access panels where protection and visibility are needed.

Thermal Stability

PET plastic sheets maintain excellent structural integrity across a broad range of temperatures, performing reliably in both cold and moderately hot environments.

While they exhibit good thermal stability for most applications, they have limitations under extreme heat compared to some high-performance plastics.

This makes PET sheets ideal for projects where consistent performance is required without exposure to excessive temperatures, ensuring durability and maintaining their physical properties over time.

Manufacturing and Production of PET Plastic Sheets

The manufacturing and production of Polyethylene Terephthalate (PET) plastic sheets is a sophisticated process that leverages the material’s inherent durability and strength, making PET an excellent candidate for a wide range of applications.

Production typically begins with the selection of high-quality PET pellets, which are melted and extruded into continuous sheets.

These sheets are then cooled and cut to the required length and thickness, ensuring they meet the specific needs of each project.

One of the key advantages of PET is the ease of access to raw materials, as PET is widely available and not generally blocked by permission or security issues.

However, when specialized additives or coatings are incorporated to enhance properties such as UV resistance or anti-static performance, manufacturers may need to obtain special permission or licenses to ensure compliance with safety and environmental regulations.

Throughout the production process, careful control of temperature, pressure, and moisture levels is essential.

Excess moisture or improper conditions can affect the quality and performance of the final PET sheet, potentially impacting its suitability for engineering, packaging, or construction applications.

By maintaining strict quality standards, manufacturers can produce PET sheets with consistent thickness, excellent durability, and reliable performance, making them a preferred material for a variety of products and uses.

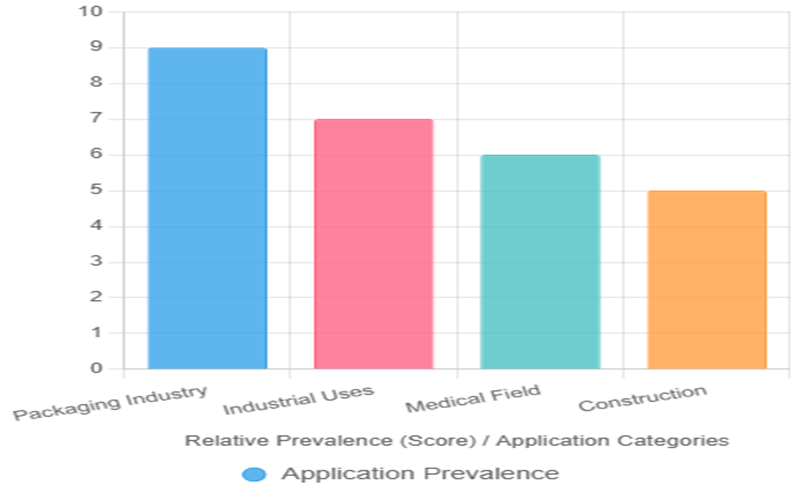

Applications Of PET Plastic Sheets

PET (Polyethylene Terephthalate) plastic sheets are versatile, durable, and highly recyclable materials widely used across multiple industries due to their excellent clarity, strength, chemical resistance, and eco-friendly properties.

Packaging Industry

PET sheets are extensively used for food containers, bottles, and trays due to their excellent clarity, strength, and chemical resistance, ensuring safe and visually appealing packaging for food and beverages that meets regulatory standards.

Manufacturers must obtain proper permission and comply with relevant safety guidelines when using PET sheets for packaging, especially in sectors involving direct food contact.

Additionally, PET packaging often includes labels with http links or QR codes containing product information and safety data, enhancing consumer access to important details via digital platforms.

Industrial

In industrial settings, PET sheets work well for signage, displays, and protective covers due to their transparency and impact resistance. These qualities make them ideal for creating durable, eye-catching signs and protective barriers in manufacturing or retail environments.

They are also used in engineering applications, including parts that require good dimensional stability and strength.

Medical Field

PET sheets are extensively utilized in the medical field for sterile packaging and critical equipment components, leveraging their excellent chemical inertness and ability to maintain sterility.

They are commonly found in medical trays, blister packs, and device housings, where their durability and resistance to chemicals ensure safety and reliability.

Additionally, PET sheets provide excellent barrier properties against moisture and contaminants, making them ideal for preserving the integrity of medical supplies and pharmaceuticals.

Their lightweight nature and ease of fabrication further enhance their suitability for various medical applications, including disposable medical devices and protective covers.

Construction

In construction, PET sheets serve as glazing and insulation panels.

Their lightweight nature, combined with good thermal stability and durability, makes them suitable for applications like window replacements and energy-efficient building solutions.

Leading brands in the industry utilize PET plastic sheets to protect structures from environmental damage while maintaining clarity and strength, ensuring both aesthetic appeal and long-term performance.

In some construction applications, PET sheets can be easily secured using zip ties, providing a simple and effective installation method.

Advantages Of PET Sheets

A major advantage of PET plastic sheets is their high impact resistance and exceptional durability. These sheets withstand substantial force without cracking or breaking, making them ideal for applications demanding robust materials. PET sheets help address the common problem of material failure due to impact or stress, making them a reliable choice for demanding applications.

This durability extends lifespan and reduces maintenance and replacement costs, contributing to overall project savings.

Another key benefit is cost-effectiveness. Compared to plastics like polycarbonate or acrylic, PET offers an affordable option with impressive mechanical performance and clarity.

This economic advantage appeals to businesses balancing quality with budget constraints.

Additionally, PET sheets resist various acids, bases, and solvents without degrading, making them suitable for food packaging, medical, and industrial environments.

They also provide outstanding optical clarity, rivaling glass, essential for applications needing clear visibility like protective barriers and displays.

Their lightweight nature eases handling and installation, reducing transportation costs and labor.

PET sheets can be easily cut, drilled, and shaped to fit custom needs, with white or clear finishes for aesthetic preferences.

They also serve as effective protective barriers, blocking unauthorized access or contamination, ideal for security and safety applications.

Overall, the combination of strength, clarity, chemical resistance, cost-effectiveness, eco-friendliness, and protective qualities makes PET plastic sheets versatile and reliable for many industries.

Disadvantages Of PET Plastic Sheets

Despite their many benefits, PET plastic sheets have some drawbacks.

Their relatively low heat resistance limits use in high-temperature applications, potentially causing deformation or loss of strength.

PET sheets are also prone to surface scratches without protective coatings, which can reduce clarity and aesthetics.

They may have limited resistance to certain solvents and strong alkalis, affecting performance in some industrial settings.

Extended UV exposure can cause slight haze or discoloration, impacting outdoor visual clarity.

Understanding these limitations helps optimize PET sheet use for durability and environmental responsibility.

PET Sheet vs PP Sheet

When comparing PET (Polyethylene Terephthalate) sheets to PP (Polypropylene) sheets, several key differences emerge that influence their suitability for various applications.

PET sheets are known for their superior clarity, higher strength, and excellent chemical resistance, making them an excellent candidate for projects requiring transparency and durability.

In PET bottle manufacturing, the initial preform is shaped like a test tube, featuring thick walls and bottle-cap threads, before being blown into its final bottle form. This tube-shaped preform highlights a key difference in processing compared to PP.

In contrast, PP sheets offer greater flexibility and resistance to fatigue, along with better resistance to certain chemicals like acids and alkalis, but they are generally less transparent and have lower impact resistance than PET.

Additionally, PET sheets tend to have better thermal stability and dimensional accuracy, which is crucial for precision engineering parts.

Choosing between PET and PP sheets depends on the specific requirements of the application, such as the need for clarity, mechanical strength, chemical exposure, and environmental conditions.

Environmental Impact And Recycling Of PET Plastic Sheets

Well-developed recycling processes for PET plastic sheets ensure these engineering materials can be transformed back into usable resources through the application of innovative techniques that significantly reduce waste and conserve resources.

PET plastics are highly recyclable, allowing them to be repurposed into a strong mixture of parts multiple times without significant loss of quality.

This recyclability helps mitigate environmental concerns and supports good sustainability initiatives in their manufacture, depending on the expected outcomes.

Extensive recycling of PET plastics reduces waste and conserves resources.

However, concerns remain about the potential for PET to leach chemicals into the environment and affect ecosystems. Effective recycling and disposal strategies are vital to address these issues.

Recycling programs in countries like Canada have shown success in increasing PET recovery rates, with many facilities processing PET sheets and bottles into new products such as fibers, films, and packaging materials.

Innovations in chemical recycling and enzymatic breakdown of PET promise a brighter future for sustainable PET use, reducing excess environmental impact.

Access And Safe Use Of PET Plastic Sheets

To maximize the benefits of PET plastic sheets while maintaining safety, it is crucial to ensure proper access and handling protocols are followed.

Users should always obtain the necessary permission and comply with relevant safety guidelines when working with PET materials, especially in environments where chemical exposure or physical stress is involved.

Proper storage and handling reduce the risk of damage, such as cracking or scratching, which can compromise the sheet’s protective qualities.

Additionally, using appropriate tools and protective equipment during fabrication and installation helps prevent accidents and ensures the material’s integrity.

By adhering to these best practices, PET plastic sheets can be safely and effectively utilized across various applications, providing reliable performance and long-lasting durability.

Conclusion

In summary, PET plastic sheets stand out as an excellent candidate for a multitude of applications, thanks to their outstanding durability, strength, and clarity.

The manufacturing process is designed to optimize material properties, thickness, and security, ensuring that each sheet meets the highest standards for quality and performance.

PET’s versatility makes it suitable for use in packaging, construction, engineering, and beyond, with its clear and strong characteristics often serving as an ideal replacement for glass or as protective films.

As the demand for reliable and high-performance materials continues to grow, PET sheets are expected to play an increasingly important role in the future of the plastics industry, both in Canada and worldwide.

While considerations such as access to raw materials, permission, and security may arise, PET’s proven track record and adaptable properties make it a good choice for a wide range of projects.

Whether your application requires transparency, strength, or durability, PET plastic sheets offer a dependable and innovative solution for today’s and tomorrow’s material needs.