In an era of increasingly diverse material options, matte acrylic sheets have emerged as a favorite among designers, artists, and manufacturers due to their unique non-glossy surface and exceptional versatility.

This lightweight, durable, and aesthetically pleasing material not only inherits the transparency and resilience of traditional acrylic sheets but also offers a soft optical effect through frosted processing, striking a perfect balance between beauty and functionality.

From interior decoration to artistic creations, from industrial manufacturing to DIY projects, matte acrylic sheets are reshaping the landscape of modern design with their boundless possibilities.

This article will guide you into the captivating world of this material, unveiling its characteristics, advantages, and wide-ranging applications to help you select the ideal material and create outstanding design works.

What Is Matte Acrylic Sheet?

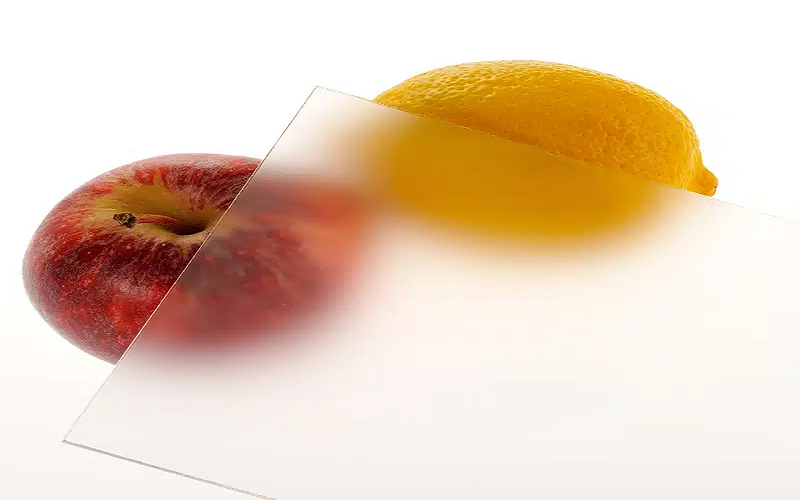

Matte acrylic sheet, also known as P95 acrylic sheet or frosted acrylic sheet, is a type of cast acrylic sheet that features a smooth, non-glossy matte finish on one or both sides.

Unlike traditional glossy acrylic, matte acrylic diffuses light softly, reducing glare and reflections, making it ideal for applications where a subtle, elegant look is desired.

This versatile material is easily cut, engraved, and shaped, which makes it perfect for a variety of creative and industrial projects.

Available in a range of thicknesses and colors, including popular matte white and black finishes, matte acrylic sheets can be customized to suit specific size requirements or custom sizes and design needs.

Their durability, long-lasting quality, and resistance to yellowing ensure that these sheets maintain their aesthetic appeal over time.

Key Advantages of Matte Acrylic Sheet

Compared to traditional glass or glossy acrylic sheets, matte acrylic sheets offer significant advantages in both functionality and aesthetics.

Firstly, their non-glare surface effectively controls light reflection, making them ideal for scenarios requiring soft lighting or glare reduction.

For instance, in photography studios, they serve as backdrop panels to minimize unwanted reflections; in lighting design, they evenly diffuse light, creating a warm ambiance.

Secondly, matte acrylic sheets boast excellent processing capabilities. They are easily laser-cut, CNC-routed, drilled, sawed, and sanded, while supporting screen printing, digital printing, and laser engraving.

The matte surface enhances the adhesion of inks and paints, making it suitable for customized patterns or text.

Additionally, this material is scratch-resistant, chemical-resistant, and has good fire-retardant properties (complying with UL94 standards), ensuring reliability in both indoor and outdoor applications.

From an environmental perspective, matte acrylic sheets are recyclable, and their production process consumes less energy. Compared to glass, they have lower transportation costs due to their lightweight and shatter-resistant nature.

Many customer reviews highlight their ease of use in DIY projects, stable quality, and resistance to deformation.

Overall, these advantages make matte acrylic sheets a preferred choice for designers and acrylic sheet manufacturers.

How To Make Matte Cast Acrylic Sheet?

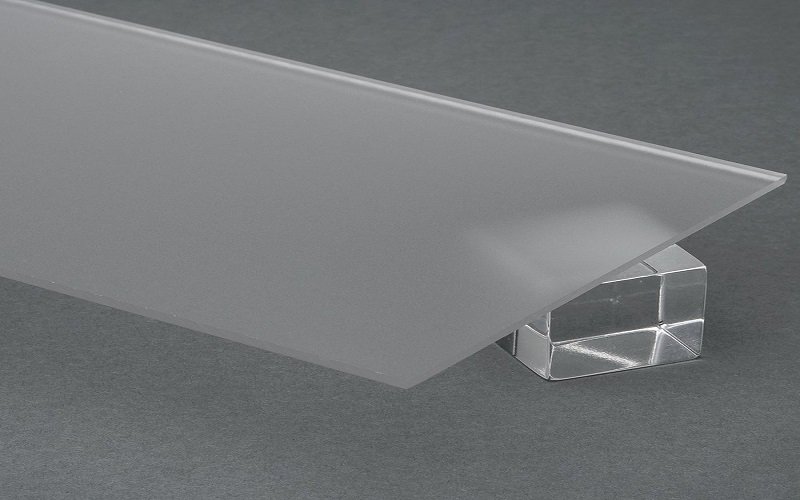

Matte cast acrylic sheets are produced through a specialized casting process that ensures their unique matte finish and superior quality. The process begins with liquid acrylic monomer being poured into a flat mold, where it undergoes polymerization to form a solid sheet.

To achieve the matte surface, the sheet is either cast against a textured mold or subjected to a surface treatment after casting.

This treatment can include sandblasting, chemical etching, or applying a matte coating, which diffuses light and reduces glare. The matte finish can be applied on one side or both sides of the sheet, depending on the desired effect and application.

The casting method allows for precise control over thickness and color, resulting in durable, long-lasting sheets that resist yellowing and maintain their aesthetic appeal. Additionally, the cast acrylic material offers excellent impact resistance and can be easily cut, shaped, and engraved, making it ideal for a wide range of applications.

Quality control measures during production ensure uniformity in thickness, surface finish, and optical properties, meeting industry standards for both functional and decorative uses.

Understanding the manufacturing process helps users appreciate the value and versatility of matte cast acrylic sheets, empowering them to choose the right material for their specific projects.

Applications of Matte Acrylic Plexiglass Sheet

Matte acrylic sheets offer versatility in elegance, making them suitable for a wide range of applications across various industries.

One of the most common uses is in signage, where the matte finish reduces glare and enhances readability under different lighting conditions. These sheets are also popular for partitions and room dividers, providing privacy while allowing light to pass through softly.

In interior design, it is commonly used for privacy partitions, cabinet doors, display shelves, and point-of-purchase (POP) displays.

For example, opaque white matte panels can serve as office partitions, providing privacy while allowing soft light to pass through.

In the fields of art and photography, matte acrylic sheets are an ideal medium. They can be used for picture frames, photographic reflectors, or art installations, reducing glare to highlight the subject.

Laser cutting enthusiasts often use them to create custom accessories such as earrings, keychains, or model parts. Black matte sheets are especially popular for their elegant “velvet-like” appearance.

Moreover, with the rise of sustainable design, matte acrylic sheets are used in furniture and architectural elements, such as matte tabletops or wall panels. Their wide range of colors—from soft pinks to deep blacks—allows designers to achieve personalized expression.

How To Choose Right Matte Acrylic Sheets For Project?

When choosing a matte acrylic sheet, first consider the application requirements:

- Transparency: semi-transparent for light diffusion, opaque for privacy

- Thickness: thin sheets for engraving, thick sheets for structural use

- Surface type: single-sided matte is suitable for reflection control, double-sided matte for uniform texture

Standard sizes can be cut according to the project, with tolerances typically ±1/32 inch and thickness variation within 5-10%. When using, avoid high temperatures (above 80°C) to prevent deformation, and use appropriate tools for cutting to maintain smooth edges.

Conclusion

Matte acrylic sheets, with their unique optical effects, durability, and ease of processing, are gradually replacing traditional materials to become a core element in modern design. Whether you are a DIY enthusiast or a professional architect, these sheets inspire limitless creativity.

With ongoing advancements in material technology, future matte acrylic sheets may incorporate smart features such as self-healing surfaces or eco-friendly formulations.

If you wish to order high-quality matte acrylic sheets, please contact MUDUSA Acrylic. We offer customized acrylic sheet products and are happy to provide more information about our offerings.