Plastic sheet lamination is a transformative process that enhances the functionality, durability, and aesthetics of plastic materials, making them indispensable across industries like packaging, construction, and automotive.

This article serves as a comprehensive guide to plastic sheet lamination, exploring its techniques, materials, benefits, and applications to help manufacturers, designers, and enthusiasts understand how this process delivers high-performance solutions for diverse projects.

What Is Plastic Sheet Lamination?

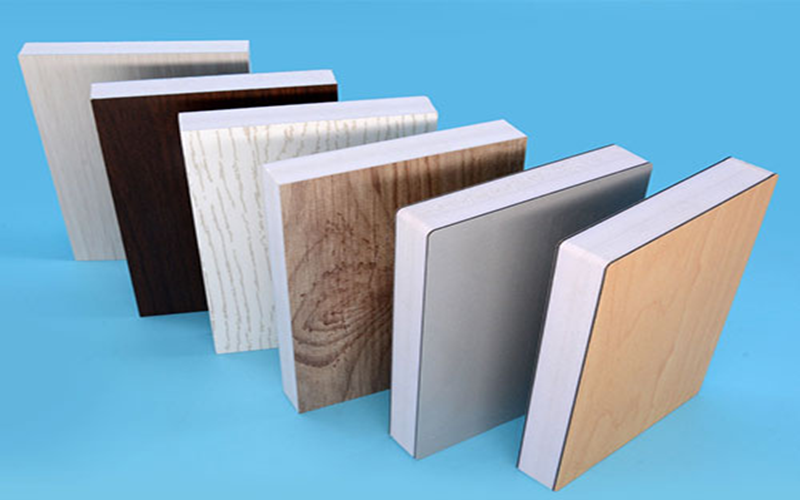

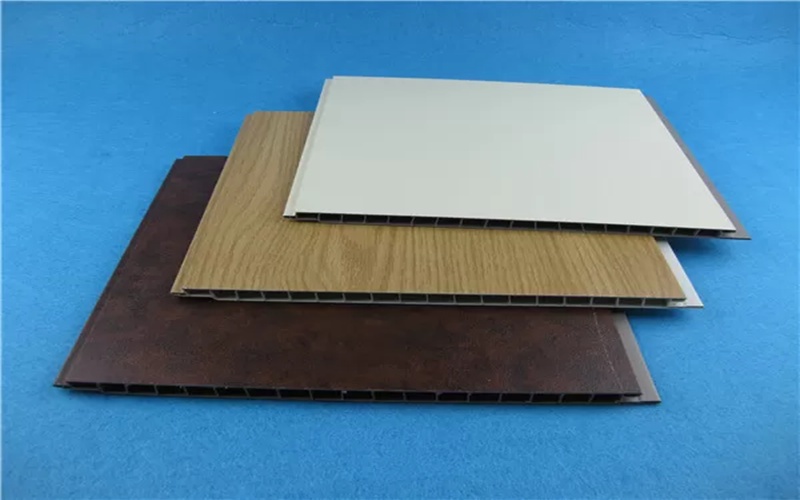

Plastic sheet lamination is a specialized process that involves bonding one or more layers of plastic sheets together or onto other materials to enhance their strength, durability, and appearance.

The lamination process can involve different types of plastics such as PVC, polycarbonate, acrylic, and PETG, each chosen based on the specific requirements of the project.

By applying heat, pressure, or adhesives, the layers are fused to create a single, cohesive sheet that is suitable for a variety of applications, from industrial components to decorative panels.

Plastic sheet lamination not only improves the physical properties of materials but also allows for customization in terms of thickness, texture, and finish, making it a versatile solution across many industries.

Materials Used In Plastic Sheet Lamination

The choice of materials is fundamental in plastic sheet lamination, directly impacting the durability, functionality, and appearance of the final product.

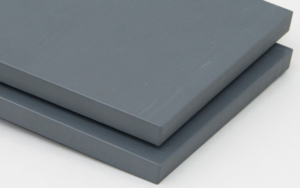

Polyvinyl Chloride (PVC)

Polyvinyl Chloride is one of the most widely used materials in plastic sheet lamination due to its excellent balance of durability, flexibility, and cost-effectiveness.

PVC sheets are highly resistant to chemicals, moisture, and weathering, making them suitable for both indoor and outdoor applications.

Additionally, PVC sheets can be easily laminated with various coatings to enhance surface properties such as scratch resistance and UV protection.

Polycarbonate (PC)

Polycarbonate is a highly durable and versatile plastic commonly used in plastic sheet lamination. Known for its exceptional impact resistance and transparency, polycarbonate sheets are ideal for applications requiring both strength and clarity.

Polycarbonate sheets can be easily laminated with other materials to enhance their surface properties, including scratch resistance and UV protection.

Additionally, the lamination process improves the overall performance of polycarbonate sheets by providing a protective layer that extends their lifespan and maintains their aesthetic appeal.

Acrylic

Acrylic is a popular material in plastic sheet lamination due to its excellent optical clarity and superior weather resistance. It provides a durable and attractive surface that is ideal for decorative and display applications.

When laminated, acrylic maintains its transparency and enhances protection against scratches and UV damage, extending the lifespan of the finished product.

This makes acrylic lamination a preferred choice for signage, retail displays, and protective covers where both aesthetics and durability are essential.

Polyethylene Terephthalate Glycol (PETG)

Polyethylene Terephthalate Glycol, is a popular material in plastic sheet lamination due to its excellent combination of toughness, chemical resistance, and ease of fabrication.

Additionally, PETG laminates can be easily thermoformed and bonded with adhesives, providing flexibility in design and manufacturing.

Overall, PETG is a reliable and adaptable choice in plastic sheet lamination, offering a balance of strength, clarity, and ease of use that meets a wide range of project requirements.

Lamination Techniques And Process

Plastic sheet lamination involves several key techniques and steps to ensure strong bonding and high-quality results.

Thermal Lamination

Thermal lamination is a widely used method in plastic sheet lamination that utilizes heat to activate adhesives or melt layers together.

Thermal lamination is especially suitable for projects requiring moisture resistance, improved surface finish, and enhanced durability.

The process is efficient and versatile, capable of handling various plastic types and sizes, making it a preferred choice for both industrial and commercial applications.

This method is ready to meet diverse project requirements, providing an easy and effective way to improve the quality and lifespan of plastic sheet products.

Pressure Lamination

Pressure lamination is a crucial technique in plastic sheet lamination that involves applying mechanical pressure, often combined with heat, to bond multiple layers securely.

This method ensures a strong adhesion between sheets, resulting in a smooth, bubble-free surface that enhances both the durability and appearance of the laminated product.

Pressure lamination is particularly suitable for projects requiring high-quality finishes and robust protection, as it effectively seals the layers together, preventing delamination and extending the lifespan of the material.

Adhesive Lamination

Adhesive lamination is a versatile plastic sheet lamination technique that uses specialized adhesives to bond plastic sheets or combine them with other materials.

This method is particularly suitable for heat-sensitive substrates that cannot withstand the high temperatures used in thermal lamination.

By carefully selecting the right adhesive, manufacturers can achieve strong, durable bonds while maintaining the integrity and appearance of the materials involved.

Co-Extrusion Lamination

Co-extrusion lamination is an advanced plastic sheet lamination technique that involves simultaneously extruding multiple layers of different plastic materials to form a single laminated sheet.

This process allows manufacturers to combine the unique properties of various plastics, such as strength, flexibility, and barrier protection, into one cohesive product.

Co-extrusion lamination is highly efficient and provides excellent bonding between layers without the need for additional adhesives or heat treatments.

Benefits Of Plastic Sheet Lamination

Plastic sheet lamination offers numerous advantages that make it an essential process in various industries.

Improved Aesthetic Appeal

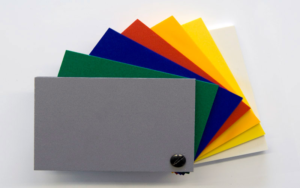

Plastic sheet lamination significantly enhances the visual appeal of materials by adding a smooth, glossy, or matte finish that makes colors appear more vibrant and surfaces more refined.

This process not only protects the underlying material but also allows for a wide variety of surface textures and effects, such as metallic, brushed, or holographic finishes, which can be customized to suit specific design requirements.

Increased Durability

One of the primary benefits of plastic sheet lamination is the significant increase in durability it provides.

Laminated sheets are designed to withstand harsh environmental conditions, including exposure to UV rays, moisture, and temperature fluctuations, which can otherwise degrade unlaminated plastic materials over time.

This enhanced durability makes laminated sheets suitable for both indoor and outdoor applications, ensuring long-lasting performance in various settings.

Ease Of Maintenance

One of the key advantages of plastic sheet lamination is its ease of maintenance. Laminated surfaces are smooth and resistant to dirt, stains, and moisture, making them simple to clean with just a damp cloth or mild cleaning agents.

This low-maintenance quality is especially valuable in environments where hygiene is crucial, such as healthcare facilities, kitchens, and schools.

Additionally, the protective laminated layer helps prevent damage from everyday wear and tear, reducing the need for frequent repairs or replacements.

Surface Finishes And Effects Of Plastic Sheet Lamination

Surface finishes and effects play a significant role in the overall appeal and functionality of laminated plastic sheets.

Special effect laminates can give a unique touch to laminated plastic sheets, making them suitable for creative applications.

Metallic effect laminates are designed to add a contemporary flair to projects, providing a modern aesthetic that is both stylish and eye-catching.

These metallic finishes can be used in a variety of applications, from packaging to interior design, adding a touch of sophistication and elegance to the information details that happen at the end. If you want to visit these options, you’ll find many exciting choices.

Brushed finishes, on the other hand, add texture to laminated plastics, enhancing the visual and tactile experience of the material.

This textured finish can make a product stand out, providing a unique look and feel that sets it apart from conventional laminates.

The variety of surface finishes and effects available in laminated plastic sheets can greatly enhance their aesthetic appeal and functionality.

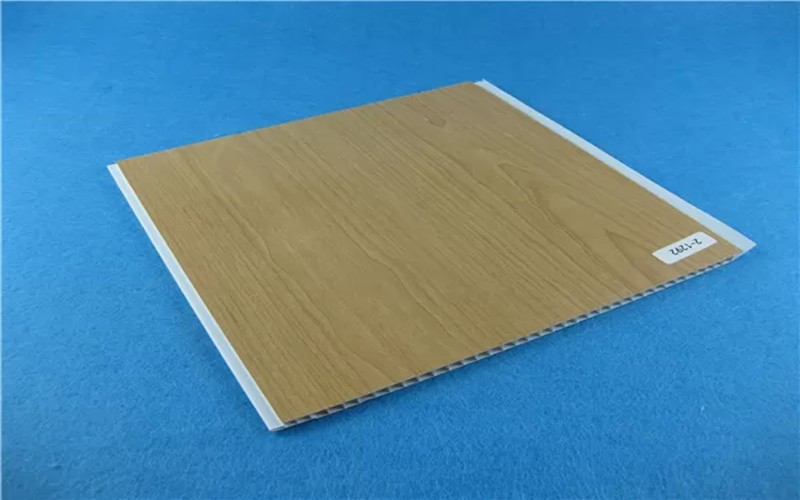

Applications Of Laminated Plastic Sheets

Laminated plastic sheets have a wide range of applications across various industries due to their enhanced durability, protection, and aesthetic qualities.

Displays

Laminated plastic sheets are widely used in displays due to their excellent weather resistance and vibrant surface finishes.

These sheets provide a durable and attractive solution for both indoor and outdoor signage, retail displays, and promotional materials.

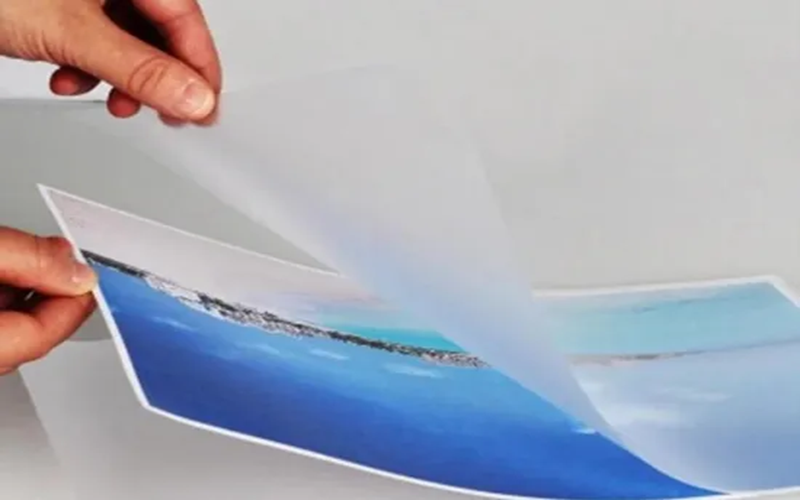

The lamination process enhances the visual appeal by protecting printed graphics and photographs from fading, moisture, and physical damage, ensuring that displays maintain their clarity and brightness over time.

Industrial Components

Laminated plastic sheets are extensively used in the manufacturing of industrial components due to their exceptional strength, durability, and resistance to wear and chemicals.

The lamination process enhances the mechanical properties and surface quality of the materials, making them suitable for applications requiring high performance and reliability.

By choosing the right combination of plastic materials and lamination techniques, manufacturers can supply tailored solutions that meet specific industrial requirements while improving the lifespan and efficiency of their products.

Anti Static Applications

Anti-static plastic sheet lamination plays a vital role in preventing the buildup of static electricity on surfaces, which can be damaging to sensitive electronic components and equipment.

These laminated sheets are specially designed with materials and coatings that dissipate static charges, making them ideal for use in environments such as electronic housings, clean rooms, laboratories, and packaging for electronic devices.

Packaging

In the packaging industry, plastic sheet lamination plays a crucial role in enhancing both the durability and visual appeal of packaging materials.

Laminated sheets provide a protective barrier that safeguards contents from moisture, dust, and physical damage, ensuring products remain intact during transportation and storage.

Additionally, lamination improves the surface finish, offering a glossy or matte effect that can make packaging more attractive on retail shelves, thus increasing consumer appeal.

Factors To Consider In Plastic Sheet Lamination

Several factors must be considered in plastic sheet lamination to ensure the best results.

Material compatibility and bonding strength are crucial aspects that determine the success of the lamination process.

Choosing the right materials and ensuring they bond well together is essential for creating durable and high-quality laminated products.

Environmental conditions also play a significant role in the lamination process, as factors such as temperature, humidity, and exposure to elements can affect the performance and longevity of the laminated product.

Cost and performance trade-offs are another important consideration. Balancing cost and performance is essential to improve the desired results in a way that fits within budget constraints.

Additionally, regulatory compliance, such as FDA regulations for food contact and UL standards for fire safety, must be taken into account to ensure the laminated products meet industry standards and safety requirements that are required.

Innovations And Trends In Plastic Sheet Lamination

The field of plastic sheet lamination is rapidly advancing, driven by ongoing innovations and emerging trends that aim to improve both performance and sustainability.

One key innovation is the introduction of eco-friendly adhesives and biodegradable laminates, which help reduce environmental impact whilst maintaining strong bonding and durability.

Another significant trend is the enhancement of surface coatings, such as advanced UV protection and scratch-resistant layers.

Automation and digitalization are transforming the lamination process itself.

Additionally, the combination of plastic sheet lamination with additive manufacturing techniques, such as 3D printing, is opening new avenues for creating complex, multi-functional laminated products.

These trends collectively contribute to the growing versatility and application range of plastic sheet lamination, making it a vital technology for industries seeking durable, high-quality, and environmentally responsible materials.

Conclusion

The versatility and importance of plastic sheet lamination cannot be overstated.

Whether you’re looking to protect important documents such as paper items, create durable industrial components, or enhance the appearance of your products, plastic sheet lamination provides a reliable and effective solution.

When selecting the right lamination process for your specific needs, it is essential to consider factors such as material compatibility, environmental conditions, and cost or performance trade offs.

Exploring emerging technologies and innovations in plastic sheet lamination can also lead to improved performance and new applications.

From eco-friendly adhesives to advanced coatings and automation, staying informed about the latest trends can help you make the most of this versatile technology.

If you visit site, you can browse a variety of laminated products built to suit different projects and applications.

The team is happy to help you find the right solution for your place of work or any other setting, ensuring the number of items you need are supplied efficiently.

Team use cookies on our site to improve your browsing experience and work continuously to provide the best content and products.

Whether you’re a buyer looking for high-quality laminated products or a seller aiming to offer the best solutions, plastic sheet lamination is a valuable tool that can elevate your projects to new heights.