Industrial plastic sheets play a crucial role across numerous industries, from manufacturing and construction to automotive and medical applications.

In this guide, we will explore the various types of industrial plastic sheets, their key properties, manufacturing processes, and wide-ranging applications.

Whether you’re a professional looking to select the right material for your project or simply interested in learning more about high-performance plastics, this article provides valuable insights to help you make informed decisions.

What Is Industrial Plastic Sheet?

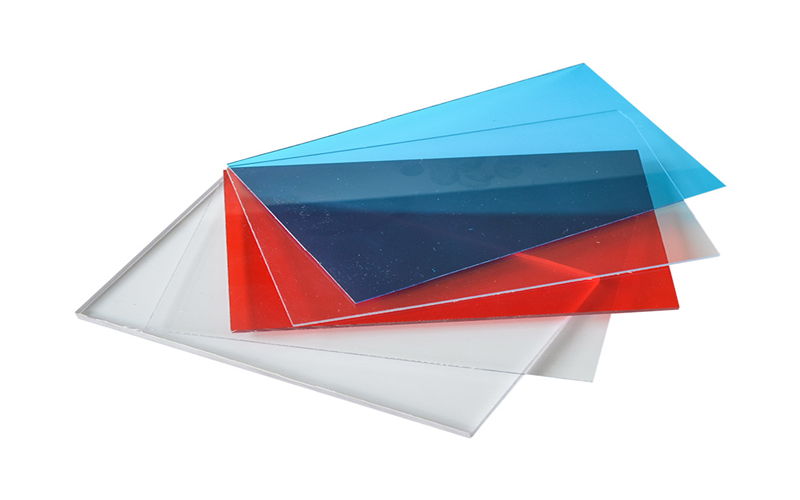

An industrial plastic sheet is a versatile and durable flat material made from various high-performance plastic materials designed to meet the demanding needs of multiple industries.

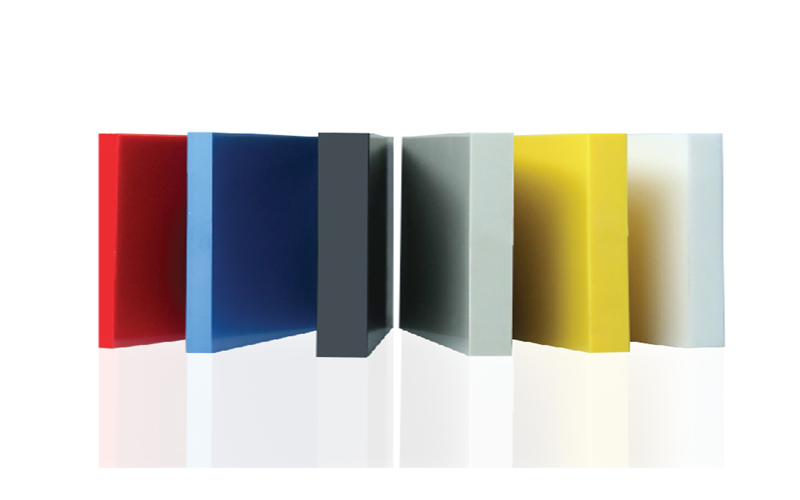

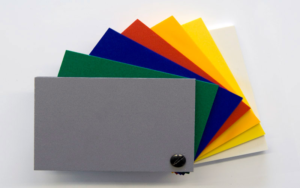

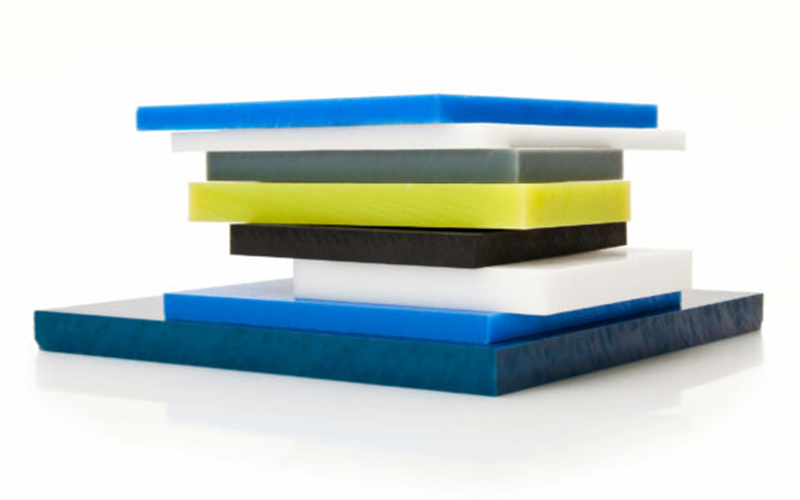

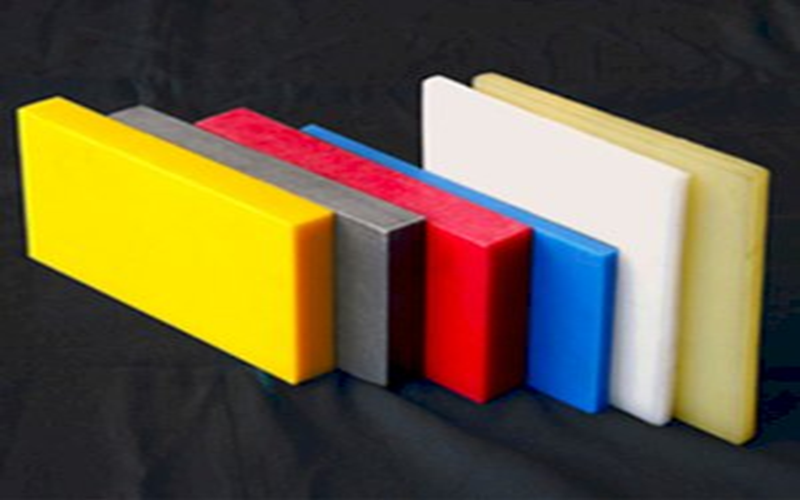

These sheets come in a broad range of thicknesses, sizes, and colors, offering extensive selection options that suit diverse applications.

These sheets can be easily cut, shaped, and fabricated into different basic shapes such as sheets, rods, tubes, and profiles, making them highly adaptable for projects ranging from automotive parts and signage to packaging and construction.

Customers often choose industrial plastic sheets for their excellent durability, cost-effectiveness, and sustainability benefits.

Access to a reliable stock of these materials, along with the ability to request custom sizes and shapes, ensures that industries can fill their project requirements efficiently and maintain high-quality standards.

Types Of Industrial Plastic Sheets

Industrial plastic sheets come in a variety of types, each designed to meet specific performance requirements and application needs.

High Density Polyethylene (HDPE) Sheet

High Density Polyethylene sheets are a popular choice in the industrial plastic sheet market due to their exceptional strength, durability, and chemical resistance.

Known for their high impact resistance, HDPE sheets can withstand harsh environments, making them ideal for applications in automotive, construction, and packaging industries.

These sheets feature a smooth surface that is easy to cut and fabricate into various shapes, including plastic rods and plastic profiles, allowing for versatile use across different projects.

Additionally, HDPE is lightweight yet remarkably tough, contributing to easier handling and reduced transportation costs. Many suppliers stock black and natural color options, catering to diverse industry needs.

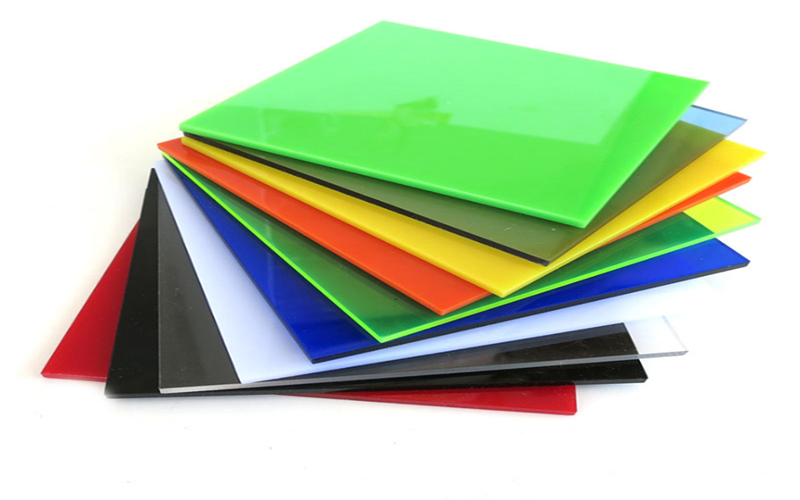

Acrylic (PMMA) Sheet

Acrylic, also known as PMMA (Polymethyl Methacrylate), is a widely used industrial plastic sheet known for its exceptional clarity and excellent weather resistance.

This material offers a smooth surface that is easy to cut and fabricate, making it a preferred choice for applications requiring both aesthetic appeal and durability.

Acrylic sheets are commonly used in signage, displays, protective barriers, and glazing due to their ability to transmit light almost as clearly as glass while being much lighter and more impact-resistant.

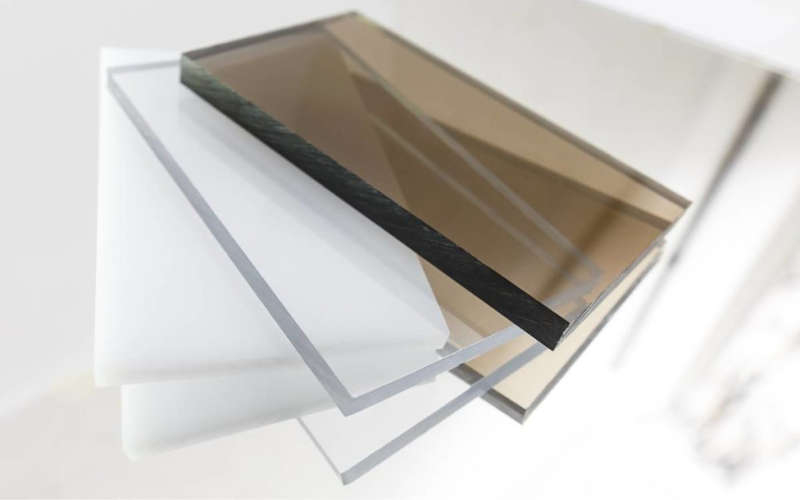

Polycarbonate (PC) Sheet

Polycarbonate sheets are renowned for their exceptional impact resistance and durability, making them a top choice among industrial plastic sheets.

These sheets offer a smooth surface and excellent optical clarity, which makes them suitable for applications requiring transparency and toughness, such as safety glazing, machine guards, and automotive parts.

Polycarbonate sheets are lightweight yet incredibly strong, capable of withstanding high impacts without cracking or breaking.

Polyvinyl Chloride (PVC) Sheet

Polyvinyl Chloride sheets are a widely used type of industrial plastic sheet known for their versatility, durability, and cost-effectiveness.

These sheets are available in various thicknesses and widths, providing flexibility to meet different project requirements.

Their durability and resistance to moisture make them ideal for both indoor and outdoor use, including flooring and wall panels.

Many suppliers stock PVC sheets in a broad range of colors and sizes, ensuring easy access and purchase for customers across industries.

This makes PVC an essential material in the line of high-performance plastics used in industrial applications throughout the USA, Canada, and beyond.

Acrylonitrile Butadiene Styrene (ABS) Sheet

Acrylonitrile Butadiene Styrene sheets are a widely used type of industrial plastic sheet known for their excellent strength, toughness, and impact resistance.

ABS combines the rigidity of acrylonitrile and styrene with the toughness of butadiene rubber, resulting in a material that is both durable and versatile.

These sheets are commonly used in automotive parts, electronics housings, and consumer products due to their ability to withstand mechanical stress and resist chemical corrosion.

Manufacturing Processes For Industrial Plastic Sheet

The manufacturing of industrial plastic sheets involves several advanced processes designed to produce high-quality, durable materials tailored for diverse applications.

One of the most common methods is extrusion, where plastic pellets are melted and forced through a die to form continuous sheets with consistent thickness and smooth surfaces.

Another widely used technique is calendering, which involves passing the molten plastic between heated rollers to create sheets of uniform thickness.

Thermoforming is also a key manufacturing process, where plastic sheets are heated until pliable and then shaped into specific forms using molds or vacuum techniques.

Additionally, lamination can be applied to combine multiple layers of plastic or other materials, enhancing the sheet’s strength, durability, or aesthetic appeal.

These manufacturing processes ensure that industrial plastic sheets meet the rigorous demands of various industries, offering versatility in form and function.

Advantages Of Industrial Plastic Sheets

Industrial plastic sheets offer numerous benefits that make them a preferred choice across various industries.

Cost-Effectiveness

Industrial plastic sheets offer a highly cost-effective alternative to traditional materials such as metals and glass.

Their lower production and processing costs, combined with long-lasting durability, help reduce overall project expenses without sacrificing quality.

Additionally, the lightweight nature of these sheets lowers transportation and handling costs, making them an economical choice for large-scale industrial applications.

Versatility

Industrial plastic sheets are incredibly versatile, making them suitable for a wide range of applications across different industries.

Available in various thicknesses, sizes, and colors, these sheets can be easily cut, shaped, and fabricated into multiple basic shapes such as rods, tubes, and profiles.

This adaptability allows manufacturers and designers to tailor materials precisely to their project requirements, whether for automotive parts, signage, packaging, or construction components.

Durability

Durability is one of the most important qualities of industrial plastic sheets, making them a reliable choice for demanding applications.

These sheets are engineered to resist corrosion, chemicals, moisture, and physical impact, ensuring they maintain their structural integrity over time.

Their high impact resistance and toughness allow them to withstand harsh environments without cracking or breaking, which is essential for industrial uses.

Limitations Of Industrial Plastic Sheets

While industrial plastic sheets offer numerous advantages, it is important to recognize their limitations to make informed material choices.

Temperature Sensitivity

While many plastics perform well under normal conditions, exposure to high temperatures can cause warping, deformation, or even chemical degradation.

For instance, materials like acrylic and PVC may soften or lose structural integrity when subjected to heat above their specific thresholds.

Always note the temperature limits provided by manufacturers to avoid compromising the quality and performance of your plastic components.

UV Degradation

Industrial plastic sheets, while highly durable, can be susceptible to UV degradation when exposed to prolonged sunlight.

Ultraviolet (UV) rays can break down the polymer chains in plastics, causing the material to become brittle, fade in color, or develop surface cracks over time.

To combat this, many industrial plastic sheets are specially treated with UV stabilizers or coatings that significantly enhance their resistance to sunlight and outdoor conditions.

Surface Scratching

Although industrial plastic sheets typically feature a smooth surface that enhances their appearance and ease of fabrication, they can be susceptible to surface scratching during handling, cutting, or use.

Scratches may affect both the aesthetic quality and, in some cases, the functional performance of the plastic sheet, especially in applications where clarity or surface integrity is critical.

Applications Of Industrial Plastic Sheets

Industrial plastic sheets are widely used across various industries due to their versatility and durability.

Construction

In the construction industry, industrial plastic sheets are highly valued for their lightweight yet durable nature.

These sheets are commonly used for wall panels, flooring, insulation, and protective barriers because they resist corrosion, moisture, and impact better than many traditional materials.

Their versatility allows them to be easily cut and shaped to fit various architectural designs and structural requirements.

Automotive

Industrial plastic sheets are extensively used in the automotive industry due to their superior durability, impact resistance, and lightweight properties.

These materials are ideal for manufacturing interior components, trims, protective covers, and under-the-hood parts that require both strength and flexibility.

High-performance plastics such as high density polyethylene and ABS are commonly chosen for their ability to withstand harsh environmental conditions, chemical exposure, and mechanical stress.

Medical

Industrial plastic sheets are extensively utilized in the medical industry due to their exceptional chemical resistance, hygienic properties, and durability.

These materials are ideal for manufacturing equipment housings, cleanroom surfaces, and protective shields that require strict compliance with health and safety standards.

Packaging

Industrial plastic sheets are extensively used in packaging due to their durability, lightweight nature, and versatility.

These sheets provide excellent protection for goods during transportation and storage, helping to prevent damage from impacts, moisture, and chemicals.

Their smooth surface and ease of fabrication allow for custom designs that fit specific packaging needs, including containers, trays, and protective wraps.

Displays

Industrial plastic sheets are widely used in displays due to their excellent clarity, durability, and weather resistance.

These sheets provide a smooth surface that enhances the visual appeal of signage, point-of-sale stands, and display cases, both indoors and outdoors.

Conclusion

Industrial plastic sheets play an essential role in various industries, providing solutions that balance performance, cost, and sustainability.

With their high impact (high imp) resistance and durable corners, these sheets exceed the expectations of many industries requiring reliable materials.

Customers can easily contact suppliers through their website to request custom pieces or shop from an extensive selection of stock items.

For your reference, detailed product content and specifications are typically available on the supplier’s page, including up-to-date information on availability and delivery dates.

This comprehensive access ensures that you can make informed decisions and efficiently fill your project needs with quality industrial plastic sheets.

Looking forward, the role of industrial plastic sheets is expected to grow even more significant as industries continue to seek materials that offer both efficiency and innovation.

Frequently Asked Questions

What Are Industrial Plastic Sheets Used For?

Industrial plastic sheets are versatile materials used in construction, manufacturing, packaging, automotive, medical, and aerospace industries.

What Are The Key Properties Of Industrial Plastic Sheets?

The key properties of industrial plastic sheets are their durability, lightweight nature, resistance to chemicals, and availability in customizable options. These characteristics make them suitable for various applications across industries.

How Are Industrial Plastic Sheets Manufactured?

Industrial plastic sheets are primarily manufactured through processes like extrusion, calendering, thermoforming, and lamination. Each method ensures that the sheets meet specific industry standards and applications.

What Are The Main Benefits Of Using Performance Plastic Materials In Industrial Applications?

Performance plastic materials in industrial applications offer benefits such as durability, versatility, cost-effectiveness, and resistance to corrosion.

What Are The Advantages Of Using Industrial Plastic Sheets?

Using industrial plastic sheets offers significant advantages such as cost-effectiveness, lightweight properties, versatile design options, and resistance to corrosion. As an industry leader, we remain committed to these advancements.