Acrylic sheets, known for their glass-like clarity and remarkable versatility, are a favorite material for creators, from DIY enthusiasts to industrial designers.

Whether crafting curved display cases, custom signage, or intricate light fixtures, how to mold acrylic sheets effectively is a valuable skill that unlocks endless design possibilities.

This guide introduces the essentials of molding acrylic sheets, offering clear steps and practical tips to ensure success in your projects.

Molding Techniques Of Acrylic Plastic Sheets

Acrylic plastic sheets, prized for their clarity and versatility, can be shaped using four primary molding techniques: casting, injection molding, extrusion, and thermoforming.

The molding process can vary depending on whether you are working with a plastic sheet of standard thickness or thinner sheets, as thinner sheets are easier to bend and require less heating time.

Each method offers unique advantages, catering to diverse applications from signage to intricate components.

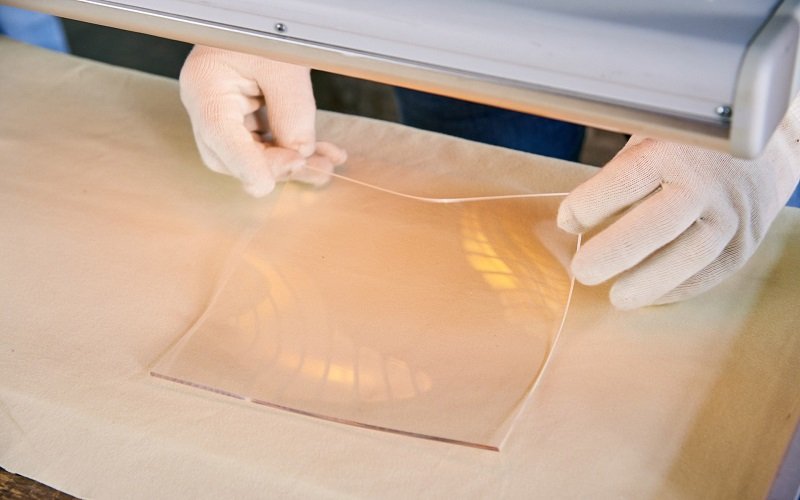

Casting

Casting involves polymerizing methyl methacrylate (MMA) in a water bath to form high-quality sheets or profiles. Post-processing requires annealing at 60°C for 2 hours followed by 120°C for another 2 hours to enhance durability.

This method excels in producing weather-resistant products, ideal for outdoor signage and displays.

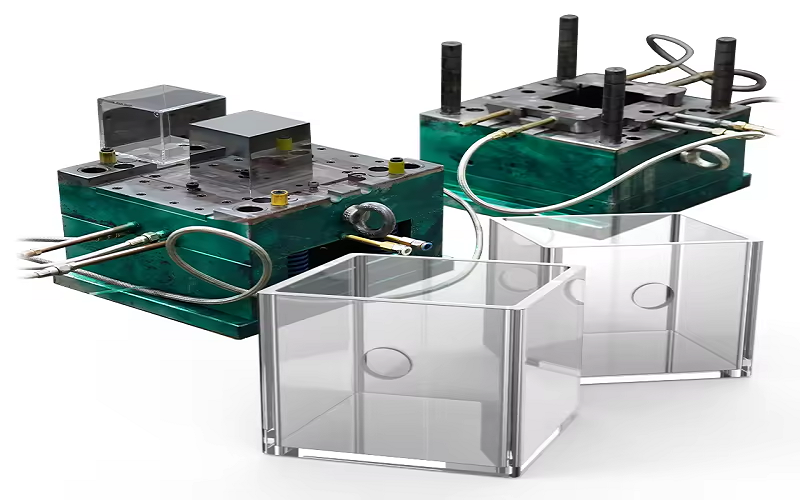

Injection Molding

Injection molding utilizes pellets produced via suspension polymerization, processed on standard plunger-type or screw-type injection molding machines.

After injection molded acrylic products, post-processing is required to relieve internal stresses. This is typically performed in a hot air circulation oven at 70-80°C.

Processing time depends on the product thickness, generally requiring approximately 4 hours.

Extrusion

Extrusion involves softening suspension-polymerized acrylic granules in an extruder to form sheets or profiles.

While the resulting sheets have slightly lower molecular weight and mechanical strength, this method is cost-effective and suited for rapid vacuum forming, commonly used for pipes, sheets, and large-scale production.

Thermoforming

Acrylic sheet can be thermoformed using several types of equipment such as vacuum, pressure, or stretching equipment, and a variety of heating methods including infrared radiation and hot plates.

This process involves heating the acrylic sheet to a pliable temperature, typically around 320°F (160°C), allowing it to be shaped over a mold to achieve the desired shape with fine details.

Thermoforming is ideal for creating complex curves and shapes that are difficult to achieve with simple bending.

The material thickness plays a crucial role in determining the heating time and the method used; thinner sheets require less heat and time, while thicker sheets may need more careful heating and handling.

Test pieces are often used to determine the optimal heating time and temperature for the specific acrylic sheet and mold combination. This helps avoid bubbles, burns, or warping during the molding process.

Drape Forming

Drape forming is a versatile technique for molding acrylic sheets into complex shapes. The sheet is heated to 160–200°C until pliable, then draped over a mold to take its shape using gravity and gentle pressure.

Heating with a heat gun or infrared radiation ensures even temperature and prevents warping. Always wear heat-proof gloves to avoid injury. This method is ideal for detailed, smooth acrylic products like signage and display stands.

Tools and Materials Required for Molding Acrylic Sheets

Before starting the acrylic sheet molding process, preparing the appropriate tools and materials is crucial for achieving high-quality results. Below is a comprehensive list of commonly used tools and materials:

Heating Equipment

Common heating tools include a household oven, heat gun, and infrared radiation heater. These devices uniformly heat the acrylic sheet to a suitable temperature, making it soft and pliable for molding.

Molds

Molds are typically made from metal, wood, or heat-resistant plastic. The tool surface should be smooth and heat-resistant to prevent marks or imperfections during molding. To avoid the acrylic sticking to the mold, cover the surface with a soft cloth or apply a release agent.

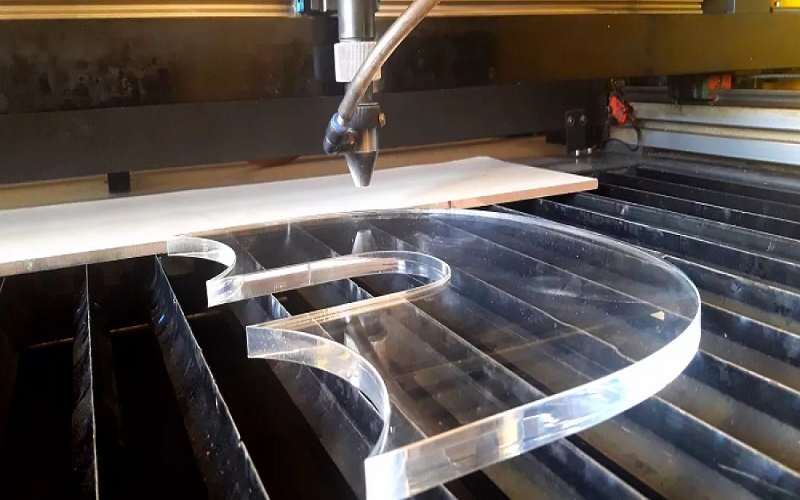

Cutting Tools

Specialized cutting tools, such as an acrylic sheet cutter or saw, allow precise cutting of acrylic sheets into the desired size and shape.

Heat-Proof Gloves

Wearing heat-proof gloves during heating and molding protects against burns and other injuries, ensuring safe operation.

Clamps and Fixtures

Clamping plates and frames are used to secure the acrylic sheet and mold, ensuring the sheet stays in place during molding to achieve the desired bend or shape.

Cooling Equipment

After molding, the acrylic sheet must cool on the mold to maintain its shape. This can be done using cold water or natural cooling methods to ensure shape stability.

Dyeing Materials

For colored acrylic, synthetic powdered dyes can be used. Before dyeing, thoroughly clean the acrylic surface to ensure even color application and strong adhesion.

With these tools and materials prepared, you can begin the heating and molding process to create high-quality acrylic products that meet your design requirements.

Tips For Effective Molding Acrylic Sheet

Molding acrylic sheets successfully requires attention to detail and adherence to best practices. Here are some essential tips to help you achieve professional results:

- Mold Prepare Properly: Ensure your mold is clean, smooth, and heat-resistant. Materials like wood, metal, or aluminum are excellent choices. Cover the mold surface with a soft cloth or release agent to prevent mark off and sticking.

- Remove Protective Film: Before heating, remove any protective film on the acrylic sheet. Leaving it on can cause bubbles and prevent a clean finish.

- Use Heat-Resistant Gloves: Always wear heat proof gloves to avoid injury when handling hot acrylic sheets.

- Slowly Heat the Acrylic: Gradually warm the acrylic sheet to around 320°F (160°C) to make it flexible without melting or bubbling. Use an oven, heat gun, or infrared radiator for even heating.

- Use Clamping Plates for Bends: To create precise bends and to bend acrylic effectively, clamp the acrylic sheet with guides to ensure the desired shape and height.

- Avoid Direct Contact with Hot Surfaces: Use tools or molds to shape the acrylic, preventing burns and preserving fine details in your design.

- Allow Proper Cooling: Let the acrylic cool completely on the mold to seal the shape firmly before removing. Cooling can be done naturally or with cold water, depending on the project.

- Prevent Bubbles and Warping: Avoid overheating and use compressed air to cool if necessary. Ensure even heating to maintain the integrity of the acrylic sheet.

Following these tips will help you mold acrylic sheets efficiently, producing durable and aesthetically pleasing acrylic products.

Finishing and Post-Processing

After molding your acrylic sheet, proper finishing and post-processing are key to achieving a polished, professional appearance.

Begin by trimming any excess material using a sheet cutter or a saw with a fine-toothed blade, which helps prevent chipping or cracking. Always work on a clean, dry tool surface to avoid scratching the acrylic during handling.

Sanding the edges of the acrylic sheet can smooth out any roughness left from cutting, and polishing will restore the sheet’s clarity and shine.

For added protection and durability, consider applying a protective film or laminate to the surface, which helps guard against scratches and UV damage.

Taking the time to carefully finish and post-process your molded acrylic sheets ensures that your final product not only looks great but also stands up to everyday use.

Conclusion

Molding acrylic sheets is a versatile and accessible technique that opens up endless possibilities for creative and functional projects.

By understanding the proper heating methods, using the right tools, and following safety precautions , you can effectively shape acrylic into a variety of forms with precision and quality.

Whether you are crafting simple bends or complex thermoformed shapes, mastering these techniques ensures professional results suitable for a wide range of applications.

ith practice and attention to detail, molding acrylic sheets becomes an invaluable skill for both hobbyists and professionals alike.