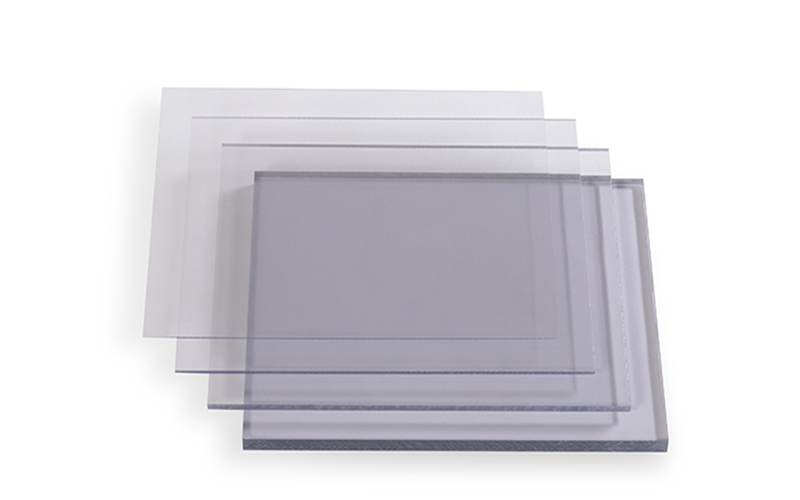

Polycarbonate sheets are a versatile and durable material widely used in construction, DIY projects, and various industrial applications.

Known for their heat resistance, impact strength, and transparency, polycarbonate sheets offer an excellent alternative to glass and other plastics.

In this step-by-step guide, we will walk you through the best tools, techniques, and safety precautions to help you cut polycarbonate sheets efficiently and accurately, whether you’re a professional or a DIY enthusiast.

What Is Polycarbonate Sheet?

Polycarbonate sheet is a type of durable plastic known for its exceptional strength, heat resistance, and clarity.

Unlike glass, polycarbonate is lightweight and virtually unbreakable, making it an ideal choice for applications requiring impact resistance and transparency.

These sheets are widely used in construction, automotive, and DIY projects due to their versatility. They can withstand harsh weather conditions and high temperatures without losing their shape or clarity.

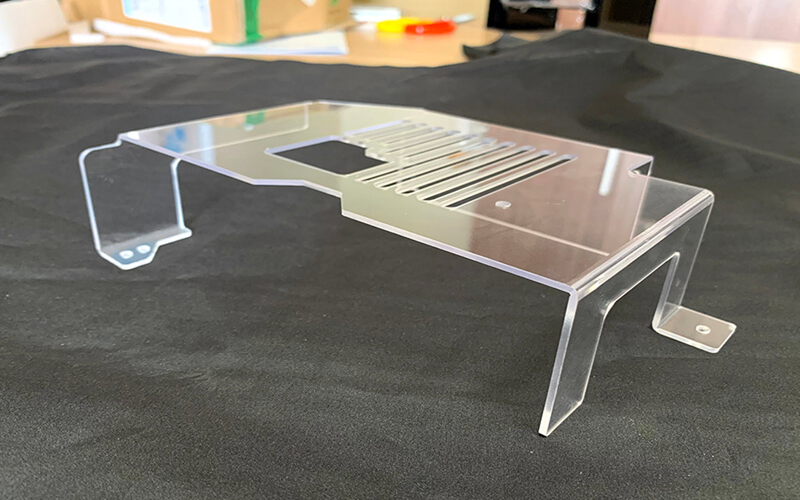

Understanding the properties of polycarbonate sheet is essential before starting the cutting process, as using the right cutting tool and technique will help achieve precise cuts without causing cracks or rough edges.

Different Tools For Cutting Polycarbonate Sheet

When it comes to cutting polycarbonate sheets, using the right tools is essential for achieving clean and precise cuts without damaging the material.

Table Saw

A table saw is one of the best tools for cutting polycarbonate sheets, especially when you need to make long, straight cuts on thicker materials.

To achieve the cleanest and most accurate cuts, it is important to use a fine toothed blade specifically designed for cutting plastics or non-ferrous metals.

Circular Saw

Suitable for cutting medium to thick polycarbonate sheets. Equip the circular saw with a sharp, fine-toothed saw blade specifically designed for plastics or non-ferrous metals.

Maintain a steady and moderate cutting speed with adjustable speed settings to prevent the material from melting or cracking due to heat buildup.

Jigsaw

A jigsaw is an excellent tool for cutting polycarbonate sheets, especially when you need to make curved or intricate cuts that other saws cannot handle.

To achieve the best results, use a fine-toothed blade designed for cutting plastics or non-ferrous metals.

Band Saw

A band saw is an excellent cutting tool for polycarbonate sheets, offering great control and precision for both straight and curved cuts, especially on thicker materials.

Using a vertical band saw fitted with a fine-toothed blade designed for plastics or non-ferrous metals ensures clean, smooth edges without cracking or melting the sheet.

Step-By-Step Cutting Methods Of Polycarbonate Sheet

Cutting polycarbonate sheets properly requires following specific steps to ensure clean, precise cuts without damaging the material.

Prepare Your Workspace

Lay the polycarbonate sheet on a stable, flat surface to provide solid support during cutting.

Ensure the area is well ventilated for safety, especially if using power tools, as cutting polycarbonate can generate heat and fumes.

Position the sheet so you have easy access to the marked cutting line, and secure it firmly using clamps or weights to prevent any movement during the cutting process.

Mark The Cutting Line

Use masking tape along the intended cutting line to prevent chipping, cracking, and scratches during the cutting process.

This protective layer helps maintain the sheet’s smooth surface and reduces the risk of damage.

Then, with a fine-tip marker or pencil, carefully draw the marked line directly on the tape to ensure maximum accuracy and visibility while cutting.

Select The Right Cutting Tool

Choose a cutting tool suitable for your sheet’s thickness and the type of cut needed to ensure precise and clean results.

For straight cuts on thick polycarbonate sheets, a table saw or circular saw equipped with a sharp, fine-toothed blade designed for plastics or non-ferrous metals is ideal.

For curved or intricate cuts, a jigsaw or vertical band saw fitted with a fine-toothed blade provides better control and smoother edges.

Wear Safety Gear

When cutting polycarbonate sheets, wearing appropriate safety gear is essential to protect yourself from potential hazards.

Always wear safety goggles to shield your eyes from flying debris and dust particles that may be generated during the cutting process.

Gloves are also recommended to protect your hands from sharp edges and accidental contact with the saw blade.

Begin Cutting Slowly

When you start cutting polycarbonate sheet, it is crucial to proceed slowly and steadily.

Begin by aligning your cutting tool precisely with the marked line, then gently guide the blade through the material without applying excessive force.

Cutting too quickly or pushing hard can generate heat, causing the polycarbonate to melt or crack, which compromises the quality of the cut.

Maintain Cutting Speed

Maintaining an appropriate cutting speed is vital when working with polycarbonate sheets.

Cutting too fast can cause excessive heat buildup, leading to melting or warping of the plastic sheet, while cutting too slowly may result in rough edges or melting due to prolonged friction.

For example, setting a moderate speed helps the fine-toothed blade glide smoothly through the material, minimizing heat generation and ensuring clean, precise cuts.

Always avoid applying excessive pressure; instead, let the saw blade do the work steadily along the marked cutting line on the masking tape.

Finish And Smooth Edges

After cutting your polycarbonate sheet, it’s important to finish the edges properly to ensure a professional look and safe handling.

Begin by carefully removing any remaining protective film from the sheet. Then, inspect the cut edges for any rough spots, burrs, or uneven surfaces.

For best results, perform this step on a stable surface in a well-ventilated area, wearing your safety gear to protect against dust and debris.

Safety Precautions Of Cutting Polycarbonate Sheet

When cutting polycarbonate sheets, safety should always be your top priority.

The process involves sharp tools and can generate plastic debris and dust, so wearing appropriate safety gear is essential.

Always use safety goggles to protect your eyes from flying chips and dust particles, and wear gloves to safeguard your hands from sharp edges and accidental cuts.

It is also advisable to work in a well-ventilated area to avoid inhaling any fumes or dust produced during cutting, especially when using power tools that generate heat.

Keep the protective film on the sheet until you finish cutting to prevent scratches and damage.

Additionally, ensure that your cutting tools are sharp and in good condition to reduce the risk of slipping or applying excessive force, which could lead to cracks or injury.

Following these precautions will help you achieve clean cuts safely and efficiently in your polycarbonate sheet projects.

Conclusion

Cutting polycarbonate sheets is a manageable task when you have the right tools, techniques, and safety precautions in place.

By selecting appropriate cutting tools such as a table saw, circular saw, jigsaw, or band saw equipped with fine-tooth or fine-toothed blades or a cutting bit designed for plastics, and by maintaining a steady cutting speed, you can achieve clean, precise cuts without damaging the heat resistant material.

Using a laser cutting machine is another excellent option for achieving highly accurate cuts, especially for intricate shapes, but it requires proper ventilation and safety measures.

Remember to prepare your workspace properly, use masking tape to protect the sheet, and always wear safety gear to protect yourself during the cutting process.

Pay attention to the angle of your cuts and use a scale to mark precise cutting lines on the protective film.

Whether you’re working on a DIY project involving wood or plastic, or a professional job, following these guidelines will ensure efficient, accurate, and safe results every time you cut polycarbonate sheet.