Acrylic sheets are widely valued for their versatility, durability, and clarity, making them a popular choice in both DIY projects and professional applications.

One of the key techniques that unlock this potential is bending acrylic sheets to achieve custom shapes and precise angles.

This article serves as a comprehensive guide to bending acrylic sheets safely and effectively, providing step-by-step instructions, essential tips, and safety precautions to help you master this skill with confidence and achieve professional-quality results.

What Are Acrylic Sheets?

Acrylic sheets, also known as plexiglass or acrylic glass, are transparent thermoplastic materials widely used as a lightweight and shatter-resistant alternative to glass.

They offer excellent clarity, weather resistance, and durability, making them ideal for various applications such as signage, displays, windows, and DIY projects.

Their ability to be easily cut, drilled, and bent with the right tools and techniques makes them a favorite choice for custom fabrication and creative designs.

Key Properties Of Acrylic Sheet

Acrylic sheets possess several key properties that make them highly suitable for bending and various other applications.

Durability

Acrylic sheets are known for their exceptional durability, making them a reliable choice for many projects.

Unlike glass, acrylic is impact-resistant and significantly more shatterproof, which enhances safety during handling and use.

Thermoplastic Nature

Acrylic sheets are thermoplastic materials, meaning they become soft and pliable when heated, allowing for easy bending and shaping into a desired shape without cracking or breaking.

During the heating process, it is important to heat acrylic evenly and slowly using tools such as a heat gun or strip heater to avoid overheating or damaging the material.

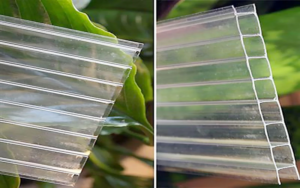

Protective Film

Most acrylic sheets come with a protective film covering the sheet surface.

This film plays a crucial role in safeguarding the acrylic from scratches, dust, and other potential damage during handling, cutting, drilling, and bending processes.

Ease Of Fabrication

Acrylic sheets are highly favored for their ease of fabrication, which allows both DIY enthusiasts and professionals to work with them effortlessly.

They can be cut precisely using common electrical tools such as saws and rotary cutters, drilled to create clean holes without cracking, and, for best results, it is important to ensure the drill bit passes through the entire length of the acrylic sheet slowly and steadily.

Tools Needed Of Bending Acrylic Sheet

To successfully bend an acrylic sheet, having the right tools is essential for safety, precision, and achieving the desired shape.

After bending, you can use acrylic glue to seal or fix the acrylic in place, ensuring durability and a smooth finish.

Heat Gun

A heat gun is an essential tool for bending acrylic sheets effectively. The heat gun heats the acrylic evenly along the bend line, making the material flexible for shaping.

Clamps

Clamps play a vital role in the acrylic bending process by firmly securing the sheet in place.

Using clamps ensures that the acrylic does not shift or slip while you apply heat and pressure, which is crucial for achieving a precise and clean bend.

Scrap Wood

Scrap wood is an invaluable tool when bending acrylic sheets, serving multiple important functions.

By placing pieces of scrap wood on either side of the acrylic along the bend line, you can evenly distribute pressure during the bending process, preventing uneven bends or damage to the sheet.

Grease Pencil

A grease pencil is an essential marking tool when working with acrylic sheets. It allows you to draw clear, visible lines directly on the protective film or acrylic surface without scratching or damaging it.

Marking the bending line clearly on the protective film or acrylic surface ensures accuracy.

Protective Gloves

Wearing protective gloves is important to avoid injury from heat or sharp edges during handling and bending.

The heating process softens the acrylic, making it pliable but also hot enough to cause injury if touched directly.

Safety Glasses

When bending acrylic sheets, wearing safety glasses is a crucial safety measure to protect your eyes from potential hazards.

The heating process can cause small particles or debris to become airborne, and accidental splinters of acrylic may occur during cutting or bending.

Preparation For Bending Acrylic Sheets

Before you begin bending acrylic sheets, proper preparation is essential to ensure a smooth and successful process.

Start by selecting the right acrylic sheet thickness for your project, as thinner sheets bend more easily while thicker sheets require more heat and care.

Always work in a clean, well-ventilated area to avoid dust and fumes, and wear protective gloves and safety glasses to guard against heat and sharp edges.

Carefully remove the protective film from both sides of the acrylic sheet along the bend line to prevent melting or residue during heating.

Use a grease pencil or permanent marker to draw a clear, straight line where you intend to bend, which will serve as a precise guide.

Additionally, gather all necessary tools such as clamps, scrap wood, and a heat gun, ensuring they are in good working condition.

Properly securing the acrylic sheet with clamps and supporting it with scrap wood will help achieve an even bend without cracks or distortions.

Taking these preparatory steps seriously not only improves the quality of your work but also enhances safety throughout the bending process.

Types Of Methods For Bending Acrylic Sheets

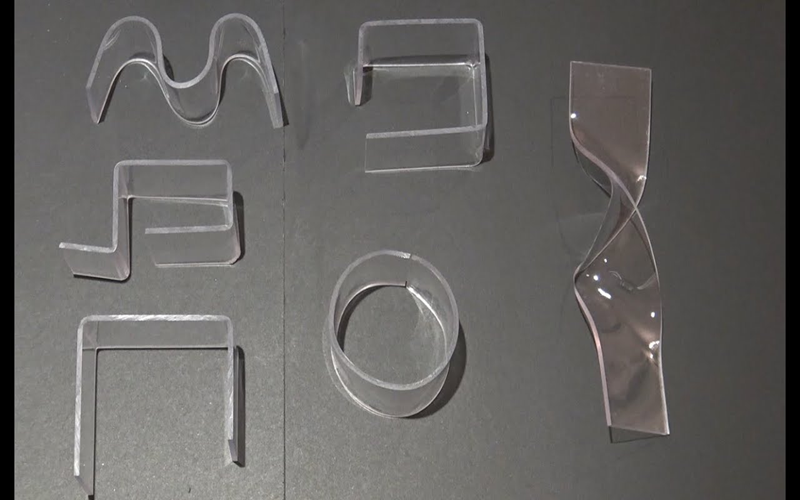

Bending acrylic sheets can be achieved through several effective methods, each suitable for different project needs and equipment availability.

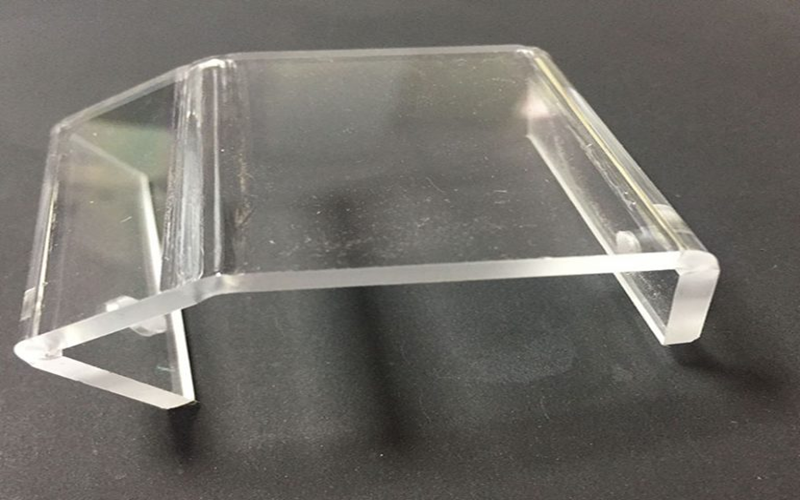

Heat Gun Bending

This method involves heating the acrylic sheet along the bend line using a heat gun until it becomes soft and pliable.

Once heated, the sheet can be gently bent to the desired angle using scrap wood or a jig. It is important to heat evenly and work slowly to avoid cracking.

Strip Heater Bending

A strip heater provides a uniform heat source along a narrow line, making it ideal for precise, straight bends.

The acrylic is placed over the heater, heated evenly, and then bent using clamps or a mold to maintain the shape until cooled.

Oven Heating

For larger sheets or complex shapes, heating the entire acrylic sheet in a temperature-controlled oven softens the material uniformly.

After removing from the oven, the sheet can be formed over molds or jigs to create curves or angles.

Cold Bending

Suitable for thin acrylic sheets, cold bending involves applying gradual pressure to bend the sheet without heating. This method requires careful handling to prevent cracking and is best for gentle curves.

Tips For Successful Acrylic Bending

To achieve the best results when bending acrylic sheets, it is essential to follow some key tips.

First, always heat the acrylic slowly and evenly along the bend line to prevent cracking or bubbling.

Using clamps and scrap wood to support the sheet during bending helps maintain a smooth, consistent curve.

Marking the bend line clearly with a grease pencil or permanent marker ensures precision. Be patient and allow the acrylic to cool completely before handling to set the new shape firmly.

Additionally, wearing protective gloves and safety glasses throughout the process safeguards against burns and debris.

Avoid overheating by monitoring the temperature carefully, as excessive heat can cause discoloration or damage.

Following these tips will help you bend acrylic sheets safely and professionally, resulting in clean, durable bends perfect for your projects.

Common Applications Of Bent Acrylic Sheets

Bent acrylic sheets are widely used across various industries and DIY projects due to their versatility and aesthetic appeal.

Signage

Bending acrylic sheets is a popular technique in the signage industry due to the material’s clarity, durability, and ease of shaping.

Bent acrylic allows for the creation of custom-shaped signs with smooth curves and clean edges, enhancing the visual appeal and professionalism of the finished product.

Furniture Design

Bending acrylic sheets opens up exciting possibilities in furniture design, enabling the creation of sleek, modern pieces that are both functional and visually striking.

Acrylic’s transparency and strength make it ideal for crafting chairs, tables, shelves, and decorative accents that add a contemporary touch to any space.

Automotive

In the automotive industry, bent acrylic sheets are widely used for various components due to their excellent durability, clarity, and ease of shaping.

These sheets are commonly formed into instrument panels, interior trim, windows, and protective covers that require precise angles and smooth curves.

Conclusion

Mastering how to bend acrylic sheet opens up a world of creative and practical possibilities for both DIY enthusiasts and professionals.

Many tutorial in website has helped countless viewers, with over 1.6M views since it was shared 10 years ago, and continues to be a trusted resource even 6 years ago and beyond, alongside related tutorials that have garnered 1.3M views.

For example, heat the acrylic on one side evenly using a heat gun or other heating tool until the sheet becomes warm and pliable.

Then, place the acrylic between two pieces of scrap wood and apply pressure to bend it to the desired angle. Using clamps is essential to hold the sheet securely in place during this process, ensuring a clean and accurate bend.

Hold the bend in place for at least five minutes to allow the acrylic to cool and set in the new shape. Covering the acrylic sheet surface with a cloth during heating can help protect it and prevent overheating at any point.

When marking your bend line, using a clamps Chinagraph pencil or permanent marker ensures clear visibility without damaging the protective film or the acrylic itself.

Always wear protective gloves and safety glasses to avoid injury during the process. It is important to determine the correct temperature and heating duration to avoid damage to the acrylic.

Using quality tools and supplies, such as those available from HLN Supplies, can make the bending process smoother and more reliable.

Whether you are creating custom signage, furniture, or automotive parts, bending acrylic sheets allows you to tailor your projects with professional-quality results.

Some guide about how to bend acrylic sheet has amassed over 238K views and 97K views on related tutorials, highlighting its value to the community of acrylic fabricators and hobbyists alike.