Heat resistant acrylic sheet is specially engineered plastic sheet that withstand high temperatures without losing clarity, strength, or durability.

These sheets offer excellent heat resistance and optical clarity, making them ideal for demanding applications in construction, glazing, signage, furniture, and light fixtures.

Their lightweight, flexible nature combined with superior weather resistance and UV protection makes them a preferred choice over glass and other plastics, especially in environments exposed to moderate heat and sunlight.

This article delves into the unique properties, advantages, fabrication methods, and versatile uses of heat resistant acrylic sheets, helping you understand why they are an ideal material for various indoor and outdoor projects.

What Is Heat Resistant Acrylic Sheet?

Heat resistant acrylic sheet is specialized panels made from polymethyl methacrylate (PMMA) enhanced with additives to withstand elevated temperatures, typically up to 160-200°C (320-392°F), far exceeding the limits of standard acrylic sheet.

Can acrylic sheets be used in high-temperature environments? Yes, heat resistant acrylic sheets are specifically engineered to handle such conditions without deforming, warping, or cracking under heat or prolonged exposure to high heat sources.

These sheets are engineered with improved thermal stability and resistance to yellowing, making them ideal for demanding environments.

They retain the lightweight, shatter-resistant qualities of regular acrylic while offering a reflective or transparent surface, depending on the coating, and provide excellent light transmission and insulation properties.

These sheets are recognized for maintaining structural integrity and optical clarity in high-heat settings.

They also enhance energy consumption efficiency, making them durable and versatile for specialized applications such as windows, doors, indoor signage, light fixtures, and outdoor use near moderate heat sources.

Moreover, heat resistant acrylic sheets offer superior weather resistance and UV protection compared to other plastics and polycarbonate sheets.

They also avoid the risks associated with direct contact with open flames or extreme temperatures.

Their compatibility with various fabrication methods and adhesives, including specialized glue, allows for customized shapes and sizes to meet specific project requirements.

This versatility makes them an ideal choice across multiple industries and construction projects.

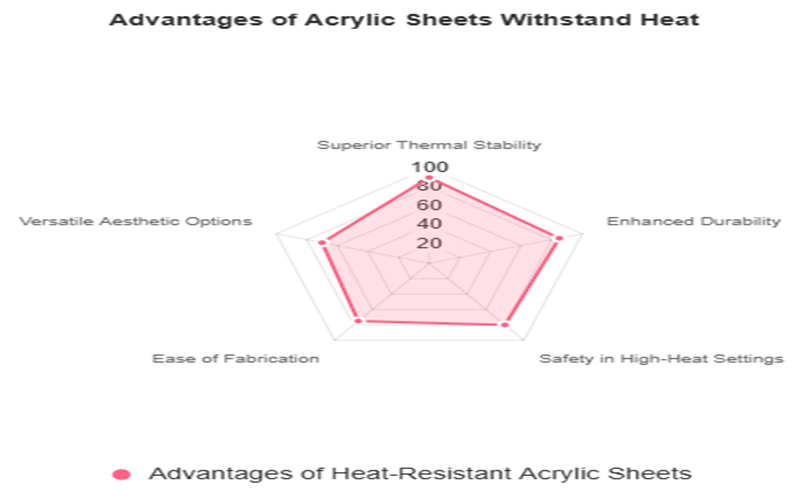

Advantages Of Acrylic Sheet Withstand Heat

Acrylic sheets designed to withstand heat offer numerous benefits, making them a top choice for applications exposed to elevated temperatures. Their enhanced properties provide both practicality and reliability.

Superior Thermal Stability

These heat resistant acrylic sheets can endure temperatures up to 200°C (392°F) without deforming or losing their structural integrity, ensuring long-term performance even in hot environments.

Their high melting point compared to other plastics makes them ideal for applications requiring sustained heat exposure without warping or melting.

Additionally, these sheets maintain excellent optical clarity and translucency under heat, unlike many alternatives that may yellow or become brittle.

Enhanced Durability

Heat resistant acrylic sheets exhibit exceptional durability, resisting warping, cracking, and deformation even under prolonged exposure to high temperatures.

This superior structural integrity extends their service life far beyond that of standard acrylic materials.

Additionally, their excellent impact strength and weather resistance make them suitable for a wide range of demanding applications, ensuring reliable performance in both indoor and outdoor environments.

Safety In High Heat Settings

Being shatter-resistant, heat resistant acrylic sheets significantly reduce the risk of injury if damaged, making them a critical advantage in both industrial and household environments.

Their excellent impact strength ensures they can withstand accidental impacts without breaking into dangerous shards, unlike glass.

Additionally, these sheets maintain their structural integrity and optical clarity even under prolonged exposure to moderate heat, providing reliable safety performance near heat sources.

This makes them ideal for applications such as protective barriers, light fixtures, and indoor signage where both heat resistance and safety are essential.

Ease Of Fabrication

Despite their impressive heat resistance, heat resistant acrylic sheets remain lightweight and easy to work with. They can be effortlessly cut, shaped, drilled, and installed using standard tools, making them highly adaptable for various fabrication processes.

Their flexibility allows for precise customization to meet specific project requirements without compromising their structural integrity or heat resistance.

This ease of fabrication, combined with their durability and optical clarity, makes these sheets an ideal material choice for both simple and complex applications.

Versatile Aesthetic Options

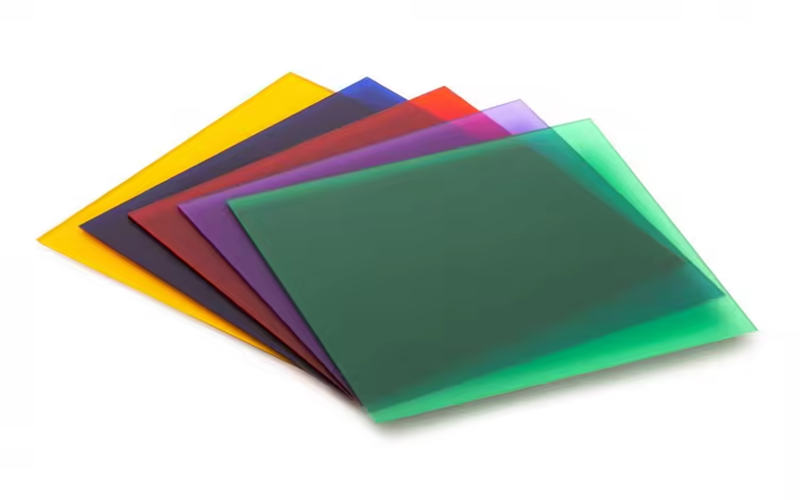

Available in clear, tinted, translucent, or mirrored finishes, heat resistant acrylic sheets offer extensive customization possibilities while retaining their superior heat-resistant qualities.

Whether you need a sleek, transparent look similar to glass or a vibrant colored option to enhance design aesthetics, these sheets can be tailored to fit your specific project requirements.

Their ability to maintain optical clarity and resist yellowing under prolonged exposure to heat and sunlight makes them an ideal choice for both functional and decorative applications.

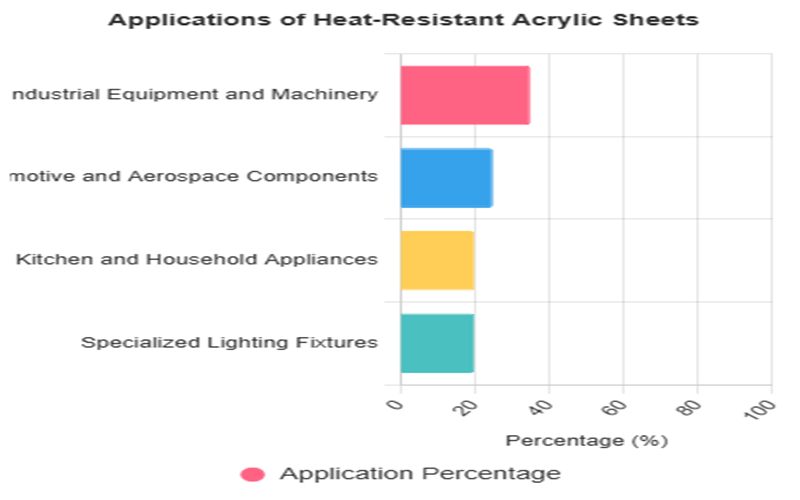

Applications Of Heat Resistance Acrylic Sheet

Heat-resistant acrylic sheets are valued for their ability to perform in high-temperature environments, making them suitable for a wide range of practical and innovative uses. Their versatility extends across multiple industries.

Industrial Equipment And Machinery

Heat resistant acrylic sheets are widely used as protective covers or viewing panels on industrial equipment and machinery exposed to heat.

Their excellent heat resistance and durability ensure safety and visibility in harsh environments, preventing damage from high temperatures while maintaining optical clarity.

These sheets also offer impact strength and weather resistance, making them suitable for prolonged use in demanding industrial settings.

Automotive And Aerospace Components

Heat resistant acrylic sheets are extensively applied in automotive and aerospace industries, particularly in interior trim, dashboards, and lightweight panels.

Their excellent heat resistance enhances durability and performance, allowing these components to withstand high temperatures encountered during operation.

Additionally, their lightweight nature contributes to overall fuel efficiency by reducing vehicle weight without compromising strength or safety.

These sheets also offer superior optical clarity and impact strength, making them ideal for both functional and aesthetic applications in demanding environments.

Kitchen And Household Appliances

Heat resistant acrylic sheets are increasingly incorporated into kitchen and household appliances such as oven doors, microwave panels, and range hoods.

They offer a safe, durable, and heat-tolerant alternative to traditional glass, providing excellent optical clarity and impact strength.

Their lightweight and shatter-resistant properties make them ideal for appliances that experience frequent use and exposure to moderate heat.

Additionally, these sheets resist yellowing and deformation even under prolonged exposure to heat and sunlight, ensuring long-lasting performance and aesthetic appeal in your kitchen environment.

Specialized Lighting Fixtures

Heat resistant acrylic sheets are widely utilized in heat-resistant lamp covers or diffusers, where they maintain exceptional clarity and structural integrity under high-temperature lighting conditions.

Their superior optical clarity and excellent light transmission make them ideal for ensuring bright, evenly distributed illumination without distortion.

Additionally, their durability and resistance to yellowing under prolonged heat exposure guarantee long-lasting performance and aesthetic appeal in demanding lighting applications.

Lifespan And Maintenance Of Heat Resistant Acrylic Sheet

Heat-resistant acrylic sheets are engineered for exceptional durability and a long service life, typically lasting 10-15 years or more when properly maintained, depending on the environmental exposure and application conditions.

Their impressive heat resistance, withstanding temperatures up to 200°C (392°F), ensures they retain structural integrity and optical clarity even under prolonged exposure to moderate heat sources.

However, factors such as direct exposure to sunlight, UV radiation, physical impacts, and chemical agents can influence their longevity.

To maximize lifespan and maintain optimal performance, regular maintenance is essential. Clean the sheets gently using a soft microfiber cloth and a mild, non-abrasive soap solution to avoid scratching or degrading the surface.

Avoid harsh chemicals like ammonia, acetone, or benzene, which can cause crazing or discoloration. Handle the sheets carefully during installation and use to prevent scratches, cracks, or warping.

When not in use, store them in a cool, dry place away from direct sunlight and extreme temperature fluctuations to prevent premature aging.

Periodic inspections are recommended to detect early signs of yellowing, warping, or surface damage.

Prompt replacement of compromised sheets helps maintain both functionality and aesthetic appeal, especially in critical applications such as industrial machinery covers, kitchen appliances, glazing, and outdoor signage.

By following these maintenance guidelines, heat resistant acrylic sheets can provide reliable, long-lasting performance with excellent weather resistance, UV protection, and impact strength, making them an ideal material choice for a wide range of indoor and outdoor projects.

Selecting The Right Heat Resistant Acrylic Sheet For Your Project

Choosing the appropriate heat resistant acrylic sheet for your project requires careful consideration of several key factors to ensure optimal performance, durability, and aesthetic appeal.

First, thoroughly assess the specific requirements of your application, including the maximum temperature exposure, environmental conditions such as sunlight and moisture, and the level of impact strength needed.

Understanding whether the sheet will face direct exposure to high heat sources or only moderate heat is crucial for selecting the right material.

Next, consider the thickness and size of the acrylic sheet.

Thicker sheets generally provide enhanced durability, better heat resistance, and improved impact strength, while the sheet dimensions should align precisely with your design to minimize waste and facilitate efficient fabrication.

Decide between different types of acrylic sheets—cast or extruded acrylic—based on your project’s fabrication and performance needs.

Cast acrylic offers superior heat resistance, higher optical clarity, and a finer finish, making it ideal for precision work and applications requiring long service life.

Extruded acrylic, while more cost-effective, is suitable for larger projects where moderate heat resistance suffices.

Additionally, evaluate the available color and finish options, including clear, tinted, mirrored, or translucent sheets.

These choices allow you to tailor the aesthetic qualities of your project while maintaining excellent light transmission, UV protection, and resistance to yellowing under prolonged heat and sunlight exposure.

Ensure that the selected heat resistant acrylic sheet is compatible with your intended adhesives, fabrication methods, and installation techniques.

Proper handling during cutting, shaping, and bonding is essential to preserve the sheet’s heat resistance, structural integrity, and overall performance.

Finally, consider any specific project requirements such as flexibility, weather resistance, or insulation properties, which might influence your choice of acrylic sheet.

By carefully evaluating these factors and choosing from the different types and grades of heat resistant acrylic sheets available, you can select the most suitable material that meets your project’s demands, enhances energy efficiency, and delivers reliable, long-lasting performance.

Summary

To wrap things up, heat resistant acrylic sheets stand out as a superior material choice due to their exceptional durability, optical clarity, and ability to withstand moderate to high heat without warping or yellowing.

These sheets are lightweight—often half the weight of glass or other plastics—making them easier to handle and install while maintaining excellent impact strength and weather resistance.

Whether used as safety barriers, in light fixtures, indoor signage, kitchen cabinets, or commercial settings, heat resistant acrylic sheets offer unparalleled advantages over traditional materials like glass and polycarbonate sheets.

Their versatility in fabrication, availability in various colors and finishes, and compatibility with adhesives and molds make them ideal for customized projects tailored to specific requirements.

We hope this guide has provided you with valuable insights and inspired you to explore the potential of heat resistant acrylic sheets further, especially as a sustainable and green choice for your next project.