Frosted acrylic sheets have become a go-to material for designers, architects, and manufacturers seeking a perfect blend of functionality and aesthetics.

Known for their translucent, light-diffusing properties, these versatile plastic sheets offer a modern alternative to glass, combining durability, lightweight construction, and a distinctive frosted finish.

This article explores everything you need to know about frosted acrylic sheets, including their properties, advantages, applications, and key considerations for use, empowering you to make informed decisions for your next project.

What Is Frosted Acrylic Sheet?

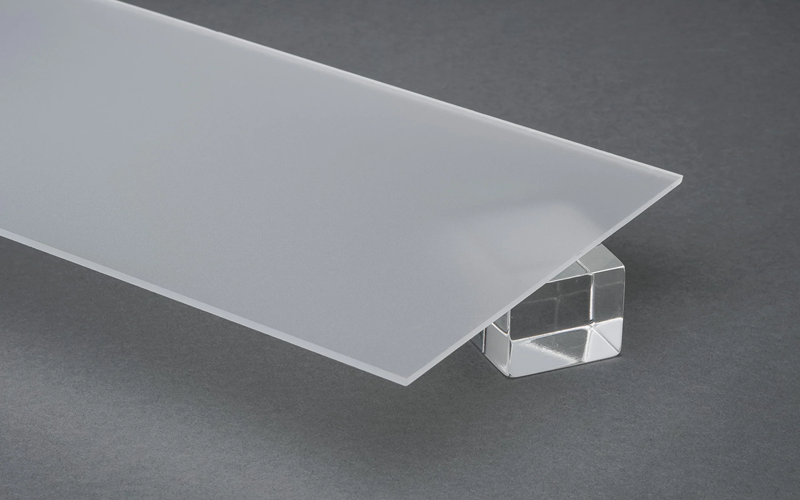

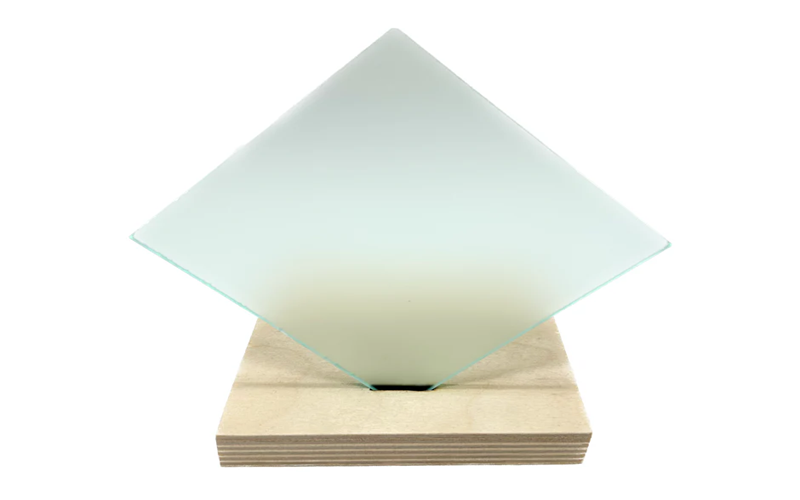

A frosted acrylic sheet is a translucent thermoplastic material, typically made from high-quality polymethyl methacrylate (PMMA), featuring a textured, frosted finish that effectively diffuses light while maintaining privacy.

This matte finish is achieved through advanced processes such as sandblasting, chemical etching, or incorporating frosting additives during manufacturing, resulting in a soft, non-glossy surface that scatters light evenly and reduces glare.

Unlike clear acrylic sheets, frosted acrylic obscures direct visibility, making it an excellent choice for applications requiring privacy without sacrificing natural light transmission.

Its combination of lightweight construction and superior impact resistance makes it a versatile and popular alternative to glass in both residential and commercial projects.

Additionally, its ease of fabrication—including laser cutting and gluing—allows you to easily search and select the ideal sheet size and thickness to suit your needs.

Key Properties Of Frosted Acrylic Sheet

Frosted acrylic sheets are prized for their unique combination of properties that make them a versatile choice for various applications.

Their optical properties, characterized by excellent light diffusion and translucency, allow them to scatter light evenly, creating a soft, glare-free illumination ideal for lighting fixtures and privacy screens.

In terms of durability, frosted acrylic sheets offer impressive impact resistance and strength, surpassing glass by being up to 10 times more resistant to shattering.

Their lightweight nature provides significant weight advantages, weighing about half as much as glass, which simplifies design, transportation, and installation processes.

Additionally, frosted acrylic exhibits good weather resistance, making it suitable for both indoor and outdoor use, as it withstands UV exposure and moisture with minimal degradation, though prolonged outdoor use may require UV-resistant coatings to prevent yellowing.

These properties collectively make frosted acrylic sheets a preferred material in industries ranging from interior design to architectural applications.

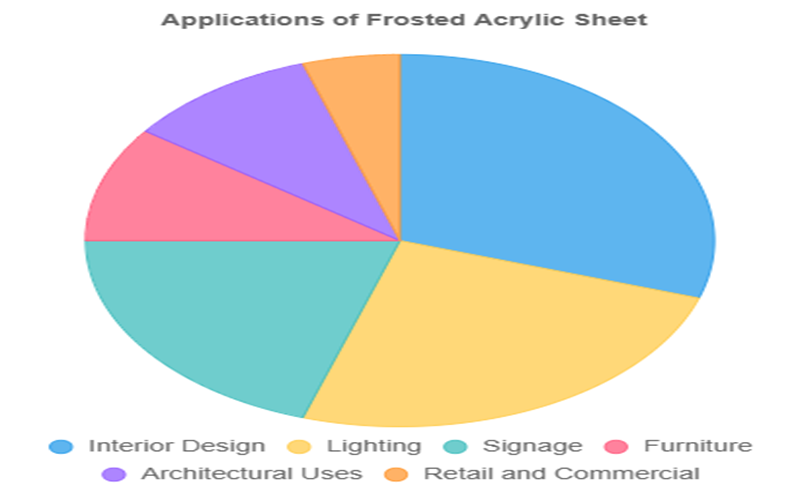

Applications Of Frosted Acrylic Sheets

Frosted acrylic sheets are widely utilized across diverse industries due to their aesthetic appeal, light-diffusing properties, and versatility.

Interior Design

Frosted acrylic sheets are widely used in interior design for partitions, wall panels, and decorative elements.

They add a modern, elegant touch to spaces while providing privacy without sacrificing natural light.

Additionally, frosted acrylic sheets are easy to cut and install, allowing designers to customize sizes and shapes to fit specific project requirements. Customers often review these sheets positively for their ease of use and aesthetic appeal.

Lighting

Frosted acrylic sheets serve as excellent diffusers for LED fixtures and lamps, evenly distributing light to reduce glare and create a soft, ambient illumination ideal for both residential and commercial settings.

Their matte finish ensures consistent light diffusion, enhancing visual comfort and atmosphere. Additionally, these sheets are easy to laser cut and fabricate to custom sizes, allowing for versatile design options.

Signage

In illuminated signs and displays, frosted acrylic enhances visibility with its translucent quality, making it ideal for backlit logos, advertising boards, and wayfinding signs that require vibrant, uniform lighting.

Its matte finish reduces glare and fingerprints on both sides, ensuring long-lasting clarity and professional appearance.

Additionally, the material’s durability and weather resistance make it suitable for both indoor and outdoor signage applications, providing a cost-effective and stylish solution for businesses and public spaces. Contact your supplier to discuss custom orders and ensure the right specifications.

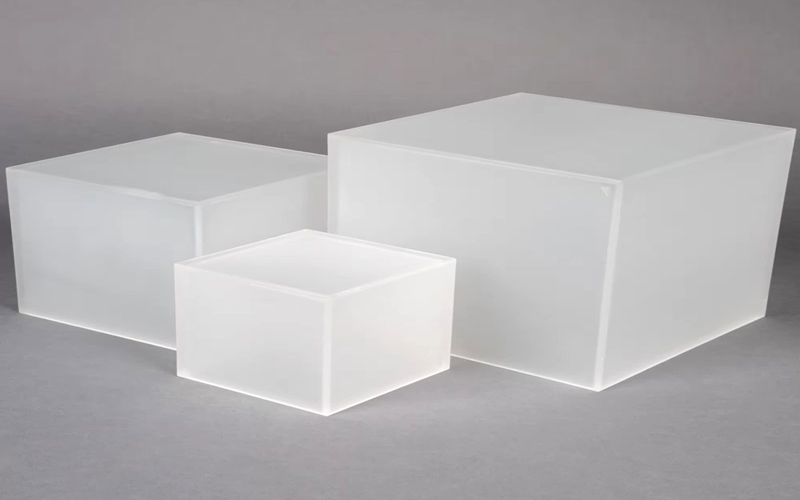

Furniture

Frosted acrylic is widely incorporated into furniture design, including tabletops, shelving, and cabinet doors. It offers a sleek, lightweight alternative to glass with enhanced durability and a contemporary aesthetic

Additionally, frosted acrylic sheets can be easily cut to size and shaped using precision machines, ensuring a perfect fit for custom furniture projects.

This versatility, combined with fast turnaround times and competitive pricing, makes frosted acrylic a great option for designers and manufacturers looking to create stylish, functional furniture pieces.

Care And Maintenance Of Frosted Acrylic Sheet

Maintaining frosted acrylic sheets is straightforward and ensures they stay in optimal condition for years.

Regular cleaning with a mild soap solution or a dedicated plastic cleaner is recommended, while harsh solvents should be avoided to prevent damage.

Using an anti-static cleaner helps reduce static buildup, minimizing dust attraction and keeping the sheets looking clean and clear.

Proper storage is crucial to prevent warping and damage. Frosted acrylic sheets should be kept away from extreme temperatures and direct sunlight to store the paper file item in the cart properly.

When handling minor scratches or haziness, a plastic polish or fine-grit sandpaper can be used to restore the surface.

For small cracks, drilling holes at the ends of the crack and applying a silicone sealant can help maintain the sheet’s integrity.

Following these care and maintenance guidelines ensures frosted acrylic sheets retain their aesthetic and functional benefits, protecting your investment and keeping them looking great over time.

Frosted Acrylic vs Cast Acrylic

Frosted acrylic and cast acrylic are both popular forms of acrylic sheeting, but they differ significantly in their properties and applications.

Frosted acrylic, characterized by its translucent, light-diffusing surface, is created through sandblasting or chemical etching to achieve a matte finish that scatters light, making it ideal for privacy screens, lighting diffusers, and decorative elements where aesthetics and light control are key.

Cast acrylic, on the other hand, is typically clear or colored with a smooth, glossy surface, offering superior optical clarity and strength, which makes it suitable for applications like aquariums, display cases, and signage requiring high transparency.

While frosted acrylic prioritizes light diffusion and privacy, cast acrylic excels in structural integrity and clarity, with the choice between them depending on whether the project demands visual appeal with diffused lighting or robust, clear material performance.

Environmental And Sustainability Considerations

A major advantage of frosted acrylic sheets is their recyclability. Unlike traditional glass, which can be difficult to recycle and often ends up in landfills, acrylic can be repurposed and reused multiple times, contributing significantly to a more sustainable and eco-friendly environment.

Advancements in acrylic manufacturing have led to more energy-efficient production methods, reducing the carbon footprint associated with frosted acrylic sheet fabrication.

Additionally, innovations in eco-friendly options, such as recycled content and low-emission processes, further enhance the sustainability of frosted acrylic sheets, making them an attractive choice for environmentally conscious projects.

Choosing frosted acrylic means opting for a versatile, durable material that not only meets functional and aesthetic needs but also supports green initiatives and sustainable practices.

Its long lifespan, combined with recyclability and efficient production, helps reduce waste and resource consumption, aligning with modern environmental standards and corporate responsibility goals.

Conclusion

Frosted acrylic sheets offer a unique blend of versatility, durability, and aesthetic appeal, making them an excellent choice for a wide range of design and functional applications.

Whether you’re creating stunning furniture, dynamic lighting fixtures, or effective signage, frosted acrylic provides the flexibility and performance needed to bring your vision to life.

Their distinctive properties—such as light diffusion, impact resistance, and UV stability—make them superior to traditional glass, while customization options in nominal size, thickness, width, and length further enhance their appeal.

When considering your purchase, the price refers to the material cost and may vary depending on sheet size and thickness.

It’s important to note the cutting tolerance, which typically allows for slight variations in dimensions measured in inches, ensuring precise fit for your project.

With a reliable supply of sheets sold at competitive prices and flexible ordering options, including the ability to create an account to track your orders, frosted acrylic remains a smart, stylish, and eco-friendly choice for both commercial and residential projects.

Explore the endless possibilities and see how frosted acrylic can transform your next project.

Frequently Asked Questions

What Are Frosted Acrylic Sheets Made From?

Frosted acrylic sheets are made from cast acrylic, also known as polymethyl methacrylate (PMMA). This material provides a durable and aesthetic finish for various applications. You can easily access a wide stock of these sheets in various sizes and thicknesses to suit your project needs.

How Effective Is Laser Cutting For Shaping Frosted Acrylic Sheets?

Laser cutting is highly effective for shaping frosted acrylic sheets, offering precision and clean edges without compromising the material’s translucent, light-diffusing properties. Many suppliers allow you to buy laser-cut sheets customized to your specifications, ensuring a perfect fit for your design.

How Does Fast Delivery Impact The Use Of Frosted Acrylic Sheets In Time Sensitive Projects?

Fast delivery of frosted acrylic sheets is crucial for time-sensitive projects, such as retail displays or event signage, where tight deadlines demand quick material availability. Having reliable access to stock and the option to buy ready-cut sheets helps streamline project timelines.

Is Frosted Acrylic More Durable Than Glass?

Frosted acrylic is indeed more durable than glass, offering greater impact resistance and being shatterproof, which enhances safety and longevity.

Are Frosted Acrylic Sheets Recyclable?

Yes, frosted acrylic sheets are recyclable, making them a sustainable choice for various applications.