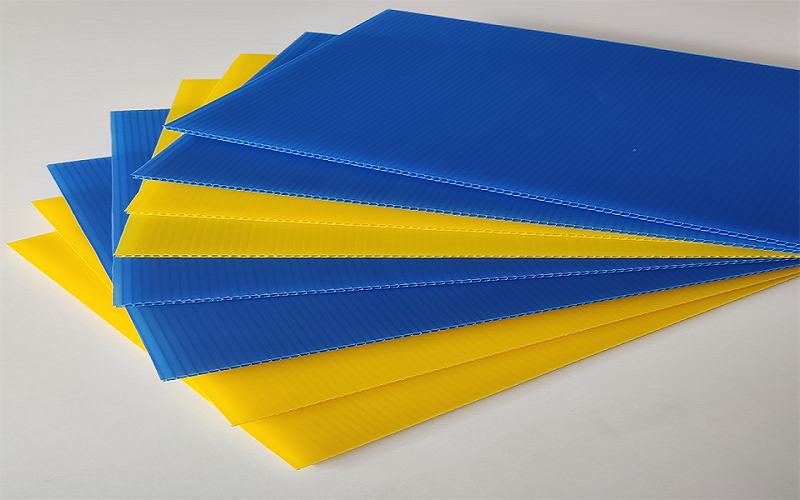

Fluted polypropylene sheet is an innovative and versatile plastic material that has gained widespread popularity across various industries.

Known for its lightweight yet durable nature, this corrugated plastic offers excellent strength and flexibility, making it ideal for a broad range of applications.

From signage and packaging to construction and agriculture, fluted polypropylene provides a cost-effective, weather-resistant, and easy-to-fabricate solution that outperforms many traditional materials like wood and corrugated fiberboard.

Whether used indoors or outdoors, its superior electrical insulation, stain resistance, and waterproof qualities make it a perfect choice for both temporary and long-lasting projects.

In the following sections, we will thoroughly explore the unique appeal of polypropylene sheets, delving into their production processes, performance benefits, and diverse applications to provide readers with a comprehensive understanding.

What Is Fluted Polypropylene Sheet ?

Also known as corrugated plastic, a fluted polypropylene sheet is constructed with a twin-wall design featuring internal flutes that provide added strength without increasing weight.

This unique structure makes the material tougher and lighter than many alternatives, such as corrugated fiberboard and wood.

Fluted polypropylene sheets are highly durable, stain resistant, and exhibit low moisture absorption, making them ideal for both indoor and outdoor applications.

Their excellent water resistance and chemical resistance further enhance their versatility, allowing them to withstand harsh environments and repeated use.

These plastic sheets are easy to cut, fabricate, and print on, which makes them a great alternative for signage, display, packaging, and construction projects.

In summary, fluted polypropylene sheets combine lightweight design with exceptional durability, making them a preferred choice for many applications where performance and cost-effectiveness are essential.

How To Manufacture Polypropylene Corrugated Plastic Sheets?

The manufacturing process of fluted polypropylene sheets involves extrusion, where polypropylene resin pellets are melted and formed into a continuous sheet with a twin-wall, fluted structure.

This process creates the characteristic corrugated plastic material that offers both rigidity and lightweight properties.

After extrusion, the sheets are cooled and cut to the desired size. Advanced manufacturing techniques ensure consistent thickness and flute size, which contribute to the sheet’s durability and strength.

Additionally, some sheets undergo surface treatments such as corona treatment to improve printability and adhesion for inks, coatings, and adhesives.

Quality control is a critical step throughout the manufacturing process to ensure the sheets meet industry standards for weather resistance, chemical resistance, and mechanical strength.

The final product is then packaged and prepared for shipment, ready to be used in a wide range of applications including signage, packaging crates, construction materials, and agricultural uses.

What Are Fluted Polypropylene Sheets Used For?

Fluted polypropylene sheets are widely used across various industries due to their lightweight, durable, and versatile properties. Below is a concise overview of their primary applications:

Packaging Industry

Used to make reusable packaging boxes, pallets, and protective pads, widely applied in logistics and transportation.

For example, packaging for fragile or protected items such as electronics, fruits, and vegetables utilizes its water resistance, moisture resistance, and durability to ensure the safety of goods.

Advertising and Display

Used to produce durable outdoor billboards, display boards, and signage. Due to its excellent waterproof and weather-resistant properties and vibrant colors, it is very suitable for commercial promotion, marketing events, and public information.

Construction

Used as temporary protective panels, floor coverings, or partitions to protect floors or walls at construction sites from damage. Additionally, it can be used for dustproofing, moisture-proofing, and sound insulation, enhancing the safety and comfort of the construction environment.

Agriculture

Used for greenhouse partitions, seedling trays, or agricultural product packaging. Its moisture resistance, ease of cleaning, and chemical resistance help improve crop growth environments and transportation efficiency.

DIY and Creative Projects

Commonly used for handicrafts, model building, or temporary structures. Due to its ease of cutting, shaping, and light weight, it is favored by creative enthusiasts and designers, suitable for various personalized applications.

Conclusion

Fluted polypropylene sheet is a versatile and durable material that offers excellent strength while remaining lightweight.

Its resistance to water, chemicals, and weather makes it suitable for a wide range of indoor and outdoor applications, from packaging and signage to construction and agriculture.

Easy to fabricate and cost-effective, it serves as a great alternative to traditional materials like wood and corrugated fiberboard.

Whether for commercial or creative projects, fluted polypropylene sheets provide reliable performance and long-lasting value.