From vibrant signage lighting up city streets to sleek home decor transforming living spaces, extruded acrylic sheets are quietly revolutionizing design and manufacturing.

Known for their crystal-clear transparency, lightweight durability, and unmatched versatility, these sheets offer a cost-effective alternative to glass and cast acrylic. Whether you’re a designer, architect, or DIY enthusiast, extruded acrylic sheets open a world of possibilities.

In this article, we’ll dive into their standout features, explore their wide-ranging uses, and reveal why they’re a go-to material for innovative projects across industries.

What Is Extruded Acrylic Sheet?

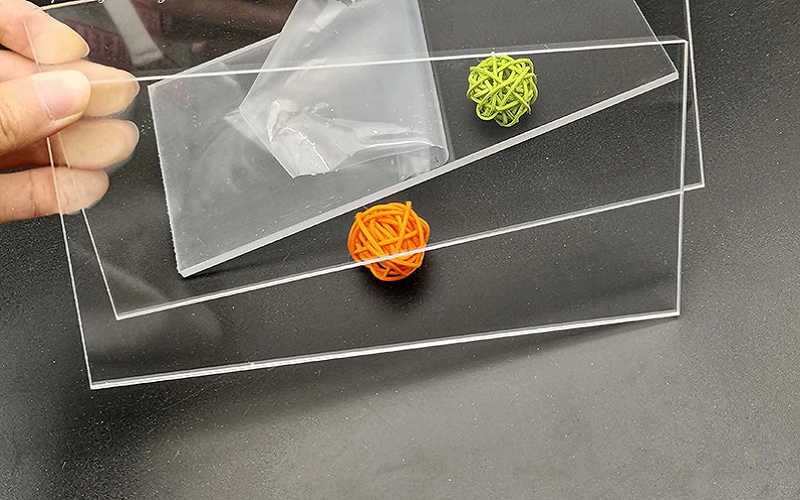

Extruded acrylic sheets are a type of acrylic sheet made through an extrusion process, which involves pushing acrylic monomers through rollers to form a continuous sheet.

This continuous method helps reduce contamination by dirt and particulates, resulting in a more stable and higher-quality product. This process ensures consistent thickness and excellent optical clarity, with light transmission rates reaching up to 92%.

These sheets are known for being lightweight, roughly half the weight of glass, yet they boast five times the strength, making them highly impact-resistant and durable. Additionally, plexiglass sheets offer a versatile alternative for various applications.

Extruded acrylic sheets are also known as plexiglass sheets and are commonly used in windows, barriers, signage, and displays due to their transparency, impact resistance, and ability to be cut to size.

Key Features Of Extruded Acrylic Sheets

Extruded acrylic sheets boast several key features that make them a preferred choice for many applications:

High Transparency

One of the standout features of extruded acrylic sheets is their transparent quality and clarity. They offer nearly the same optical clarity as glass but are significantly lighter.

This high light transmission makes them perfect for applications where visibility and light are crucial, such as in illuminated signs and display cases made from lucite acrylic plexiglass.

Extruded acrylic sheets are available in transparent, translucent, and opaque options, allowing for different levels of light diffusion and privacy.

Lightweight and Durable

Extruded acrylic sheets are both lightweight and durable, making them an ideal choice for a wide range of applications. Weighing only half as much as glass, they are easy to handle, transport, and install, reducing labor and costs.

Despite their light weight, these sheets offer exceptional impact resistance—up to 17 times stronger than glass—making them perfect for safety-critical uses like protective barriers and machine guards.

Additionally, they resist weathering, UV rays, and chemicals, ensuring long-term durability with minimal maintenance, even in harsh indoor or outdoor environments.

Impact and Moisture Resistant

These sheets are highly impact resistant, making them safer alternatives to glass in many situations. Their moisture-resistant properties prevent warping and degradation, even in humid or wet environments, ensuring longevity and reliability.

UV Resistance and Optical Clarity

Extruded acrylic sheets maintain excellent optical clarity over time, resisting yellowing due to UV exposure. This UV resistance makes them suitable for outdoor applications where prolonged sunlight exposure is expected.projects.

Malleable and Easy to Work With

One of the standout qualities of extruded acrylic sheets is their malleability. They can be easily bent, shaped, and thermoformed without cracking, allowing for creative and complex designs. This flexibility makes them ideal for custom fabrication projects where unique shapes and forms are required.

Wide Range of Thickness and Sizes

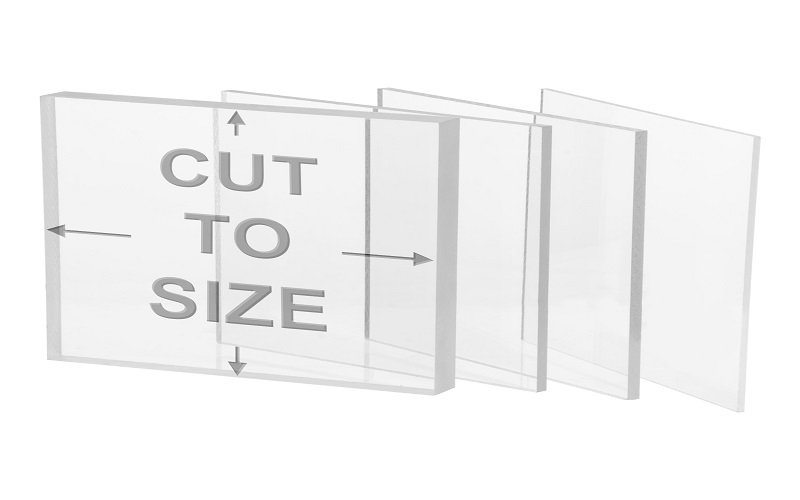

Extruded sheets come in a variety of thicknesses, typically measured in inches, to suit different needs. Whether you need a thin sheet for lightweight applications or a thicker one for added durability and impact resistance, extruded acrylic sheets offer options that can be cut to size for precise dimensions.

Limitations of Extruded Acrylic Sheets

While extruded acrylic sheets offer numerous advantages, they also have some limitations to consider when planning your project:

Lower Optical Clarity Compared to Cast Acrylic: Extruded acrylic sheets have slightly reduced optical clarity due to the continuous extrusion process, which may introduce minor imperfections. They are less suitable for high-precision optical applications, such as camera lenses or medical devices, where cast acrylic is preferred.

Susceptibility to Scratches: The surface of extruded acrylic is less scratch-resistant than glass or cast acrylic. Without protective coatings, it can develop fine scratches over time, particularly in high-traffic or exposed environments like retail displays.

Limited Heat Resistance: Extruded acrylic has a lower melting point than cast acrylic, making it more prone to deformation under high temperatures or prolonged heat exposure. This limits its use in applications like high-heat industrial settings or near open flames.

Tolerances and Dimensional Variations: The extrusion process can result in slight variations in thickness or flatness compared to cast acrylic, which may affect precision in applications requiring exact tolerances, such as intricate machinery components.

Used For Extruded Plexiglass Sheets

Extruded plexiglass acrylic sheets are widely used across various industries due to their durability, clarity, and versatility.

They are commonly found in architectural glazing, retail displays, protective barriers, and signage. Their impact-resistant and moisture-resistant properties make them ideal for environments that demand both strength and aesthetic appeal.

In the industrial sector, these sheets serve as machine guards, equipment covers, and safety shields, providing protection without obstructing visibility.

In residential and commercial settings, extruded acrylic sheets are popular for window replacements, aquarium panels, and decorative lighting fixtures. Their ability to be cut to size and formed into complex shapes also makes them a favorite among DIY enthusiasts and fabricators.

Moreover, extruded plexiglass is often used in transportation, food processing, and healthcare industries, where hygiene and durability are critical.

The sheets’ UV resistance ensures longevity even under constant sunlight exposure, making them suitable for outdoor applications such as greenhouse glazing and outdoor signage.

With such a broad range of applications, extruded acrylic sheets continue to be a preferred material choice for projects requiring a balance of performance, appearance, and cost-effectiveness.

Customization Options For Extruded Acrylic Plexiglass Sheet

Extruded plexiglass acrylic sheets, widely known as custom acrylic sheets, offer a remarkable range of customization options to meet diverse project needs.

Their versatility makes them a go-to material for designers, manufacturers, and DIY enthusiasts alike. Here are the key ways you can tailor custom acrylic sheets to suit specific applications:

Variety of Finishes: Custom acrylic sheets are available in multiple finishes, including clear, tinted, frosted, mirrored, or colored options. Clear sheets provide glass-like transparency (up to 92% light transmission), while tinted or colored sheets add aesthetic flair for signage, decor, or branding. Frosted finishes offer a diffused look for privacy panels or modern lighting designs, and mirrored sheets are ideal for retail displays or decorative accents.

Flexible Thickness Options: Extruded acrylic sheets come in a wide range of thicknesses, typically from 1 mm to 25 mm or more, allowing for precise selection based on project requirements. Thinner sheets are perfect for lightweight applications like picture frames, while thicker sheets provide structural strength for architectural glazing or industrial guards.

Custom Sizes and Shapes: Custom acrylic sheets can be cut to exact dimensions using tools like laser cutters or CNC machines, ensuring a perfect fit for projects ranging from small DIY crafts to large-scale installations like skylights or aquariums. Their ability to be shaped through cutting, drilling, or thermoforming supports intricate designs, such as curved displays or custom furniture.

Specialized Coatings and Additives: To enhance performance, custom acrylic sheets can be treated with coatings for added scratch resistance, UV protection, or anti-static properties. Additives like impact modifiers can be included during production to boost durability, making them suitable for high-traffic environments or outdoor use.

Surface Textures and Patterns: Beyond standard smooth surfaces, custom acrylic sheets can feature textured or patterned finishes for unique visual effects or improved grip in applications like flooring or shelving. These options allow for both functional and decorative customization.

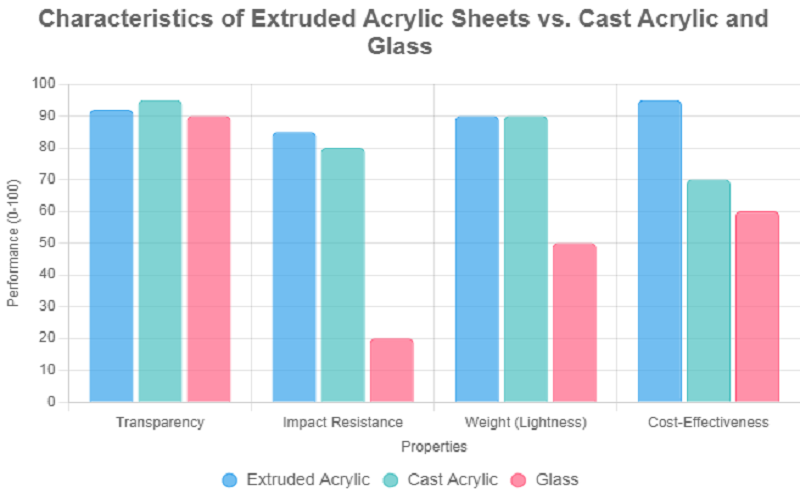

Extruded Acrylic Sheet vs Cast Acrylic Sheet

When it comes to choosing between extruded acrylic sheets and cast acrylic sheets, understanding the differences in manufacturing processes and properties is crucial.

Extruded acrylic sheets are produced through a continuous process, resulting in uniform thickness and lower molecular weight compared to cast acrylic. This makes them cost-effective and ideal for projects where budget and speed are priorities.

On the other hand, casting cast acrylic is made through a more labor-intensive process, which involves pouring acrylic monomer into molds to form sheets. This process results in a higher molecular weight and superior optical properties, but it also contributes to a higher price point.

Cast acrylic is often chosen for high-end applications where superior aesthetics and durability are required.

Cutting extruded acrylic is generally quicker and less expensive, but it may result in rougher edges that need additional finishing work. In contrast, cast acrylic typically offers cleaner cuts with less need for post-processing.

Ultimately, the choice between extruded and cast acrylic depends on the specific requirements and constraints of your project.

How To Calculate Cost For Cut-to-Size Extruded Acrylic Sheets?

Calculating the cost for cut-to-size extruded acrylic sheets involves considering several factors. The primary components of the price include the cost of the material, cutting, and handling charges based on the specified dimensions. Understanding these factors can help in budgeting and ensuring that the project remains cost-effective.

One of the key factors affecting the price is the thickness of the acrylic sheet. Thicker sheets generally cost more than thinner ones.

Additionally, the specific dimensions ordered, including length and width, play a significant role in determining the overall cost. Customized features such as edge finishing and pre-drilled holes can also add to the price.

Many acrylic sheet manufacturers offer fast processing for cut-to-size orders, often completing them within one to two business days. This quick turnaround time in the production process is beneficial for projects with tight deadlines, allowing for efficient planning and execution.

Tips for Working With Extruded Acrylic Sheet

Working with extruded acrylic sheets can be a rewarding experience if done correctly. For straight cuts, using a scoring knife is effective, but it requires practice to avoid jagged edges. For cutting curves, a jigsaw or coping saw works well, provided the surface is masked to prevent scratches.

When using a bandsaw with acrylic, consider the following tips:

- Maintain a slow blade speed to prevent heat buildup that could melt the acrylic.

- Use a fine-toothed blade specifically designed for acrylic to achieve clean cuts, avoiding aggressive cutting tools.

- Sand the edges of cut acrylic to smooth out rough spots, starting with a lower grit and progressing to finer grits.

Using coolant, such as water or alcohol, during cutting can help reduce heat and improve the finish of the cut. It’s also essential to support the acrylic sheet properly while cutting to prevent bending, which can lead to cracks. Lastly, always wear gloves and safety glasses to protect against sharp edges and potential shattering.

Ordering and Sizing Extruded Acrylic Sheets

When it comes to ordering extruded acrylic sheets, flexibility and precision are at the forefront. These sheets are available in a broad range of sheet sizes, thicknesses, and vibrant colors, making them suitable for many applications—from industrial glazing to creative displays.

Thanks to the continuous extrusion production process, extruded acrylic sheets offer exceptional dimensional stability and improved UV resistance, ensuring your projects stand the test of time and sunlight exposure.

One of the standout benefits of extruded acrylic is its impact resistant and moisture resistant properties. Lighter than glass but just as transparent, these sheets are easy to handle and install. Their lower melting point compared to cast acrylic means they are easier to cut, bend, glue, and form, allowing for quick fabrication and customization without sacrificing strength or optical clarity.

Ordering is straightforward: customers can select the exact thickness, width, and length needed, or take advantage of cut-to-size services for a perfect fit. Most cut-to-size orders are processed within one to two business days, so your project can stay on schedule.

If you need guidance on sizing or have questions about the production process, expert support is readily available to help you choose the right extruded acrylic sheets for your needs.

Extruded acrylic sheets also offer a smooth, polished surface and are available in a variety of colors, including transparent, blue, gray, pink, green, orange, purple, bronze, and more.

The extrusion process uses rollers and a catalyst to trigger a chemical reaction, resulting in a strong, durable material with a consistent finish. For added customization, you can request features like rounded edges or polished surfaces to enhance both appearance and functionality.

To ensure a precise fit, it’s important to consider the tolerance and nominal dimensions of your acrylic sheets. Whether you’re working on a large industrial project or a small creative endeavor, extruded acrylic sheets provide a reliable, lightweight, and versatile solution.

With so many options for thickness, color, and size, you can shop with confidence knowing your order will be tailored to your exact specifications and shipped promptly to your door.

Summary

Extruded acrylic sheets are a versatile and durable material that offers exceptional optical clarity, lightweight nature, and high impact resistance. Their wide range of applications, from signage and construction to retail displays and home decor, highlights their adaptability and utility.

As we’ve explored, the choice between extruded and cast acrylic sheets, understanding customization options, and knowing how to calculate costs are crucial for making informed decisions. Armed with these insights, you can confidently incorporate extruded acrylic sheets into your projects, reaping the benefits of this remarkable material.