Custom plastic sheets have become increasingly essential in various industries due to their versatility and adaptability.

This article aims to explore the benefits, diverse applications, and the process involved in creating custom plastic sheets, helping businesses and individuals understand how these materials can enhance their next project with optimized performance and design.

What Are Custom Plastic Sheets?

Custom plastic sheets are specially manufactured plastic panels tailored to meet specific size, thickness, material, and finish requirements for various applications.

Custom plastic sheets can be cut to size, drilled with holes, shaped with curves, and finished with polished edges to perfectly suit the needs of construction, manufacturing, signage, and design projects.

This customization ensures minimal waste, faster project turnaround, and a precise fit, making custom plastic sheets a versatile and cost-effective solution for many industries.

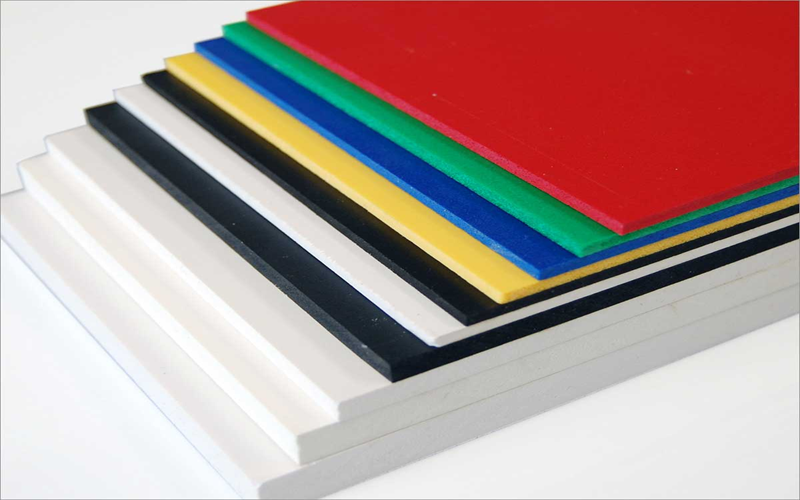

Types Of Custom Plastic Sheets

Custom plastic sheets come in a variety of types, each designed to meet specific project needs and applications.

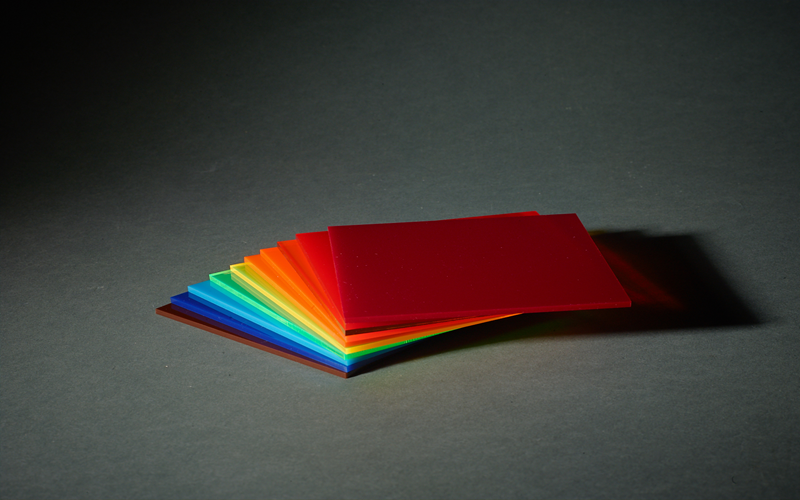

Acrylic Plastic Sheet

Known for their exceptional clarity and transparent qualities, acrylic sheets are lightweight yet durable, making them ideal for applications that require a glass-like appearance with enhanced impact resistance.

Acrylic sheets also offer excellent weather resistance and can be easily cut to size, drilled, or shaped using a scoring tool, ensuring versatility and precision for your next project.

Plexiglass Sheet

A popular brand of acrylic plastic, plexiglass offers excellent impact resistance and is often used as a lightweight alternative to glass in windows, aquariums, picture frames, and other applications requiring clear, durable materials.

Its versatility allows it to be easily cut to size, drilled, and shaped with precision, making it a preferred choice for custom plastic sheet projects.

Polycarbonate Sheet

These sheets are highly impact-resistant and provide superior strength and durability.

Polycarbonate is commonly used in safety glazing, machine guards, and outdoor applications due to its excellent UV resistance and weatherability.

In addition to its toughness, polycarbonate offers great versatility, allowing it to be easily cut, drilled, and shaped to meet precise project specifications.

ABS Sheet

Acrylonitrile Butadiene Styrene (ABS) sheets are known for their exceptional toughness, chemical resistance, and impact strength.

These qualities make ABS sheets highly suitable for demanding applications such as automotive parts, electronic housings, consumer products, and various industrial components.

Their versatility allows easy customization including cutting, drilling, and shaping to meet precise project specifications, making ABS a popular choice among businesses and customers seeking durable and reliable custom plastic sheets.

HDPE Sheet

High-Density Polyethylene (HDPE) sheets offer excellent chemical resistance, low moisture absorption, and outstanding durability.

These qualities make HDPE sheets widely used in construction, food processing, marine applications, and other demanding environments.

Their versatility allows easy customization, including cutting, drilling, and shaping, to perfectly suit specific project needs while ensuring long-lasting performance and minimal maintenance.

PTFE Sheet

Polytetrafluoroethylene (PTFE) sheets provide outstanding non-stick properties, exceptional chemical resistance, and high-temperature tolerance.

These qualities make PTFE ideal for demanding industrial applications such as gaskets, seals, liners, and components exposed to harsh chemicals or extreme heat.

PTFE sheets can be easily customized by cutting, drilling, and shaping to fit precise project requirements, ensuring reliable performance and extended service life in various engineering plastics applications.

Custom Plastic Sheet Manufacturing Process

The manufacturing process of custom plastic sheets involves several precise steps to ensure the final product meets specific requirements.

This comprehensive process allows businesses and customers to receive custom plastic sheets that are ready to use in a wide range of applications, delivering both precision and efficiency for their next project.

Material Selection

Selecting the appropriate material is a crucial step in the custom plastic sheet manufacturing process.

Depending on the specific requirements of your project, factors such as durability, transparency, chemical resistance, and environmental conditions must be considered.

Popular materials include acrylic for its clarity and lightweight nature, polycarbonate for superior impact resistance and UV protection, ABS for toughness and chemical resistance, HDPE for moisture resistance and durability, and PTFE for high-temperature tolerance and non-stick properties.

Cutting To Size

Cutting custom plastic sheets to precise dimensions is a critical step in the manufacturing process. Utilizing advanced techniques such as laser cutting and scoring tools ensures clean, accurate cuts with minimal material waste.

Whether working with acrylic, polycarbonate, or other engineering plastics, precise cutting helps streamline assembly and installation, ultimately saving time and reducing costs for your next project.

Shaping And Forming

Custom plastic sheets can be expertly shaped and formed using advanced techniques such as bending, thermoforming, and CNC machining.

These methods enable precise creation of curves, holes, and complex shapes tailored specifically to your project’s unique requirements.

This process ensures minimal material waste and accelerates project turnaround times, delivering high-quality, custom-finished parts that meet exact specifications and elevate the overall performance of your next project.

Finishing Touches

The finishing touches on custom plastic sheets play a vital role in enhancing both their aesthetic appeal and functional performance.

This stage includes polishing edges to achieve a smooth, professional look, applying protective coatings to increase durability and resistance to scratches or UV damage, and adding custom textures or patterns to improve grip or visual interest.

These finishing options allow you to tailor your custom plastic sheet precisely to your project’s needs, ensuring not only a perfect fit but also an amazing final product that stands the test of time.

Applications Of Custom Plastic Sheets

Custom plastic sheets are incredibly versatile and find applications across a wide range of industries and projects.

Architecture

In architecture, custom plastic sheets play a crucial role by offering versatile solutions that combine aesthetics with functionality.

These sheets are commonly used as durable barriers, protective panels, and glazing materials that provide excellent weather resistance and impact protection.

Their lightweight nature and ease of customization allow architects and builders to create innovative designs that maximize natural light while ensuring safety and durability.

Display

Custom plastic sheets are an excellent choice for display applications due to their versatility, clarity, and durability.

Whether you need to create eye-catching retail signs, protective display cases, or point-of-sale materials, these sheets can be precisely cut, shaped, and finished to meet your exact specifications.

Their lightweight nature and resistance to impact make them ideal for both temporary and permanent displays, while their ability to be customized in various thicknesses and finishes allows you to choose the perfect look and feel for your space.

Automotive

In the automotive industry, custom plastic sheets play a vital role in manufacturing durable, lightweight, and chemically resistant components.

Materials like ABS and polycarbonate are commonly used to create interior parts, protective covers, and structural elements that require high impact resistance and long-lasting performance.

These custom plastic sheets can be precisely cut, drilled, and shaped to fit specific vehicle designs, ensuring a perfect fit and enhanced functionality.

Medical Equipment

Custom plastic sheets play a vital role in the medical equipment industry by providing materials that meet strict hygiene and safety standards.

Sheets made from acrylic, PTFE, and other engineering plastics are frequently used for equipment housings, protective barriers, and non-stick surfaces.

These materials offer excellent chemical resistance, durability, and ease of cleaning, which are essential for maintaining sterile environments.

Conclusion

Custom plastic sheets offer unparalleled versatility and adaptability across a wide range of industries and applications.

These sheets, along with related products like rods, tubes, tubing, and mirrors, provide durability, chemical resistance, and impact strength while allowing customization in size, shape, and finish.

With a well-stocked shop and multiple locations across the USA, customers have easy access to a wide range of plastics and components.

The knowledgeable team is always ready to answer your questions and help you sort through the available materials to find the right matter for your project.

Ordering custom plastic sheets and related products has never been easier or more efficient, with reliable shipping options that can turn your order around in minutes.

Investing in these high-performance products means securing a complete solution that enhances your next project with both functionality and aesthetic appeal.