Acrylic sheets have become a “star product” across various fields such as advertising, home décor, and industry due to their unique material properties.

As an upgraded alternative to glass, acrylic sheets not only offer high transparency, excellent plasticity, and outstanding weather resistance but can also be customized according to customer requirements to meet various complex applications.

Nowadays, more and more acrylic sheet manufacturers provide professional customization services to ensure that every acrylic sheet meets precise customer specifications and high-quality standards, making it the preferred material in the market. Let’s explore the complete process of customizing acrylic sheets in the following content!

Introduction to Acrylic (Plexiglass) Sheets

Acrylic sheets, often referred to as plexiglass sheets, are a versatile plastic material made from polymethyl methacrylate (PMMA).

Renowned for their outstanding strength, durability, and crystal-clear optical clarity, acrylic sheets have become a staple in a wide range of industries.

Whether you’re working on home improvement projects, creating eye-catching commercial displays, or seeking durable solutions for industrial applications, acrylic sheets offer a cost effective solution that combines performance with visual appeal.

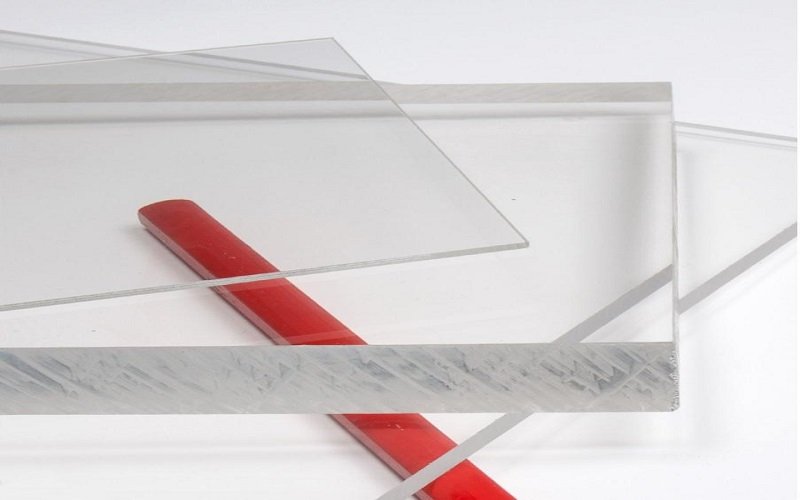

Available in various forms, including extruded acrylic sheets and cast acrylic sheets, this material can be tailored to meet the specific needs of any project.

The adaptability of acrylic makes it a popular alternative to traditional glass, providing the same transparency with added benefits such as lighter weight and greater impact resistance.

As a result, acrylic sheets are widely used for everything from protective barriers and signage to furniture and decorative elements, making them an essential material for both professionals and DIY enthusiasts.

Types Of Acrylic Sheets

Acrylic sheets come in several types, each designed to meet different requirements and preferences.

Extruded Acrylic Sheets

Extruded acrylic is produced by pushing PMMA pellets through a die, resulting in sheets with consistent thickness and a smooth, uniform texture. This process makes extruded acrylic a practical choice for projects that require precise dimensions and a cost-effective approach.

Cast Acrylic Sheets

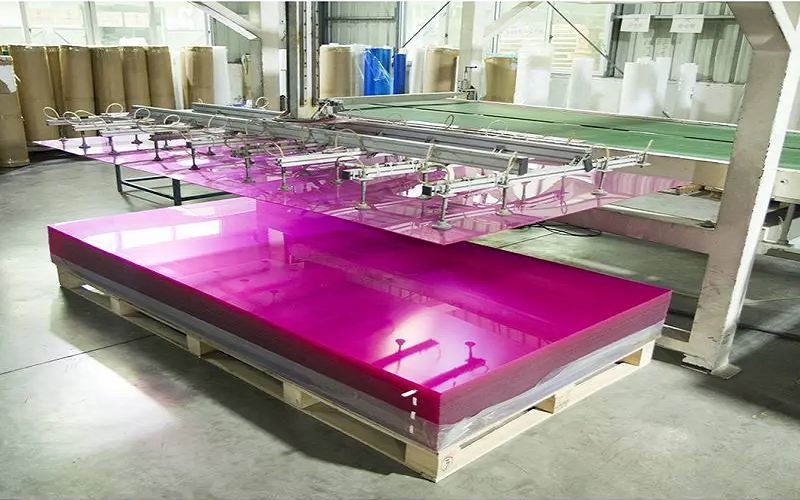

Cast acrylic sheets, on the other hand, are created by pouring liquid PMMA into molds, allowing for greater flexibility in producing complex shapes and thicker sheets.

Cast acrylic is known for its higher molecular weight, which provides enhanced strength, improved thermal stability, and superior optical clarity. This makes cast acrylic ideal for applications where structural integrity and a flawless finish are essential.

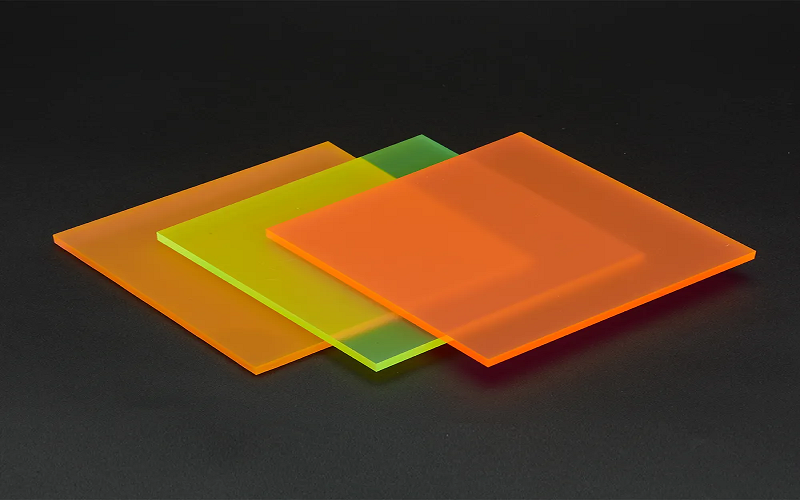

For those seeking a unique look, colored acrylic sheets are available in a wide range of opaque colors and finishes.

Options such as a matte surface or a protective film can be added to meet specific design or functional needs. Whether you need sheets for signage, decorative panels, or intricate shapes, the variety of acrylic materials ensures you can find the perfect match for your project’s requirements.

Why Choose Custom Acrylic Sheets?

Custom acrylic sheets are widely used in commercial applications such as signage, displays, and menu boards, where their aesthetic appeal and functionality enhance branding and product presentation in business settings.

Whether you are looking to create stunning display stands or protect valuable exhibits, custom acrylic sheets offer unique value and help achieve both creative and functional goals.

Excellent Optical Properties

One of the most compelling reasons to choose acrylic sheets is their exceptional optical performance.Acrylic sheets have a light transmittance of up to 92%, surpassing the clarity of ordinary glass, which typically transmits around 88% of light.

This crystal-clear quality makes acrylic an excellent choice for showcasing products or artworks, allowing every detail to shine through in a transparent manner.

Acrylic sheets can be customized with various colors, textures, and patterns, such as frosted or mirrored finishes, or laser engraving, to create visually stunning effects.

You can also select acrylic sheets with specific light diffusion properties to create privacy, reduce glare, or enhance visual effects in architectural and display projects.

Lightweight And Durable

Compared to glass, acrylic sheets weigh only half as much but offer more than 10 times the impact resistance.

This means they are not only easier to transport and install but also can withstand accidental collisions, making them especially suitable for high-traffic environments. Typical cast and extruded ¼ inch plexiglass weighs roughly 1.45 lbs per square foot.

Acrylic can also be enhanced with UV-resistant or scratch-resistant coatings to extend its lifespan, making it ideal for a variety of indoor and outdoor applications.

Flexible Design

The flexibility of custom plexiglass panels allows for endless design possibilities, enabling you to choose any size, thickness, or shape to suit your project’s specific needs.

You can personalize your sheets with laser-engraved logos and apply special surface treatments that enhance both the aesthetic appeal and functionality of the acrylic sheets.

Shaping techniques such as machining and laser cutting make it possible to create unique and intricate designs tailored precisely to your requirements.

This high level of customization ensures that your acrylic sheets perfectly match your creative vision, making them an ideal choice for innovative and custom projects.

High Cost-Effectiveness

Acrylic sheets offer a cost-effective solution without compromising on quality. They typically cost 20%-30% less than glass or polycarbonate while maintaining high standards of performance. The ease of processing acrylic sheeting, such as through laser cutting and thermoforming, reduces production time and costs.

Additionally, the low maintenance requirements of acrylic, which can be kept looking pristine with simple cleaning, further contribute to long-term savings. Opting for acrylic sheets offers excellent value for your investment with outstanding results.

Can Custom Plexiglass Be Cut Into Complex Shapes?

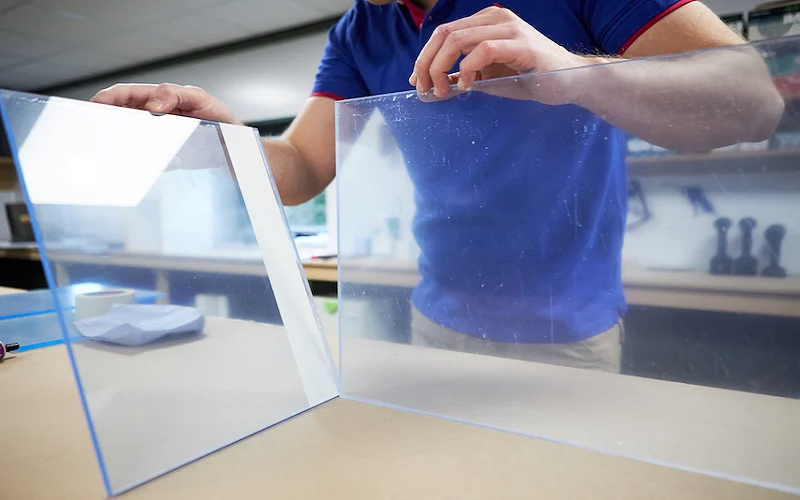

Absolutely! One of the standout benefits of custom plexiglass sheets is their ability to be cut into complex shapes with precision and ease.

Advanced cutting technologies such as laser cutting and CNC routing allow manufacturers to create intricate designs, curves, and detailed patterns that perfectly match your project requirements.

Whether you need elaborate signage, unique display stands, or specialized machine guards, custom cut plexiglass can be tailored to fit any shape or form. This flexibility opens up endless possibilities for creative applications, enabling designers and fabricators to bring their most ambitious ideas to life with accuracy and consistency.

Moreover, cut-to-size plexiglass retains its structural integrity even when shaped into complex forms, thanks to its high impact resistance and superior thermal stability. This makes it an excellent choice for both decorative and functional uses across commercial, industrial, and residential projects.

If your project demands precise, intricate shapes, custom plexiglass sheets can be manufactured to your exact specifications, including rounded edges, radius corners, and holes for mounting or installation. This level of customization ensures a perfect fit and finish, elevating the overall quality and appeal of your final product.

Customization Options For Acrylic Sheets

Customization is a key advantage of acrylic sheets, allowing you to tailor them to your specific needs with options such as specific thicknesses, dimensions, edge finishes, and intricate designs.

You can also add holes for installation or mounting purposes, as well as choose rounded edges or radius corners for smooth, curved features that enhance both safety and aesthetics.

This flexibility ensures you receive the perfect same material for your project, no matter how unique or complex your requirements may be, resulting in acrylic sheets that are not only functional but also visually appealing—significantly enhancing your home improvement projects and other applications.

Thickness and Dimensions

When it comes to thickness and dimensions, acrylic sheets offer a wide range of options:

- Standard thicknesses can vary from 0.06 inches to 2 inches, providing flexibility for different applications.

- Thin sheets are suitable for lightweight projects.

- Thicker sheets offer added structural integrity.

- Various dimensions are available to ensure the sheets fit perfectly into your project, whether it’s for table tops, displays, or protective barriers.

Acrylic plastic can be custom cut to size acrylic to match your specific needs, including clear acrylic custom cut plexiglass acrylic options.

Extruded acrylic sheets usually have less precise thickness tolerance than cast acrylic sheets. However, both types can be tailored to meet exact specifications, ensuring the right material for your project.

Such customization allows for the creation of acrylic sheets that are both functional and aesthetically pleasing, balancing thickness and dimensions perfectly.

Color and Transparency

Acrylic sheets offer a spectrum of color and transparency options to match your design vision:

- Transparent: Crystal-clear sheets with 92% light transmission, ideal for showcases or protective covers.

- Translucent: Frosted or tinted options for diffused lighting effects, perfect for signage or privacy panels.

- Opaque and Colored: Choose from a wide range of colors (e.g., vibrant red, sleek black) to align with brand identity or decor themes.

Edge Finishing and Polishing

Achieving a polished and professional look on acrylic sheets requires proper edge finishing and polishing. Specialized tools used include:

- Diamond polishers

- Flame polishers

- Cloth wheel (for hobbyists)

- Polishing block (for hobbyists)

Proper edge finishing improves the overall appearance of acrylic sheets, making them suitable for high-end applications like retail displays and signage.

Polishing residue can be effectively removed using a felt cloth or a soft cotton cloth, ensuring that the edges are smooth and clear.

Edge finishing not only improves the aesthetics of acrylic sheets but also enhances their durability by preventing chips and cracks. Attention to detail ensures that your acrylic sheets look professional and are durable.

Laser Cutting and Engraving

Laser cutting enables precise and intricate designs on acrylic sheets. This method uses a laser to cut through the acrylic, creating clean and accurate edges. It is ideal for custom projects requiring detailed designs like personalized signage, machine guards, or decorative panels.

The technology behind laser cutting ensures that the acrylic sheets are cut to exact specifications, providing a high level of precision and consistency. Additionally, laser cut techniques enhance the overall quality of the finished products, allowing you to cut plexiglass with the same precision.

Laser engraving can add unique designs and details to acrylic sheets. The process uses a laser to etch patterns or logos onto the acrylic surface, creating a permanent and visually striking effect. Laser engraving adds a touch of personalization to your acrylic sheets, making them stand out and perfectly reflect your brand or design vision.

Maintenance And Care for Acrylic Sheets

Regular maintenance and care keep your acrylic sheets looking their best. Regular cleaning of acrylic sheets is best achieved by:

- Using warm mild soap and a soft microfiber cloth to prevent scratches.

- For heavily soiled acrylic, using a compressor to blow off dust before washing with soapy water can be beneficial.

- Avoiding chemical cleaners like benzene and thinner, as they can damage the acrylic surface.

To prevent static charge that attracts dust, using antistatic cleaners when maintaining acrylic sheets is recommended. If your acrylic sheets become scratched or damaged, polishing them can restore their clarity and make them look new again.

Proper maintenance ensures that your acrylic sheets remain clear and attractive, providing long-lasting value for your investment.

Custom Acrylic Sheets: Complete Customization Process

The process of customizing acrylic sheets involves several key steps, from initial communication to final delivery.

Each step is crucial in ensuring the final product meets your specifications and exceeds expectations. By following a structured process, you can achieve high-quality custom acrylic sheets that are tailored to your specific needs.

Demand Communication

The first step in the custom acrylic sheet process is demand communication. This involves:

- Confirming the specifications of the acrylic sheets, including dimensions, thickness, color, and intended use (such as indoor decoration or outdoor advertising).

- Providing sketches, reference images, or 3D models to help clarify details.

- Specifying special requirements, such as edge polishing or scratch-resistant coatings.

Effective communication ensures all project aspects are understood, allowing for accurate planning and execution. This initial step sets the foundation for the entire customization process, ensuring the size plexiglass products meets your needs and expectations.

Material Selection

Choosing the right material is crucial for achieving desired results. Based on your budget, environmental durability, and manufacturing complexity, various options are available.

Cast acrylic, with its superior optical performance and high light transmittance, is ideal for high-end displays or complex projects like museum showcases.

Extruded acrylic, on the other hand, is cost-effective and suitable for large-scale production, such as advertising signs or protective covers.

Design And Sample Confirmation

Once the material is selected, the next step is design and sample confirmation. Designs are optimized using CAD software to ensure precise dimensions.

Small-scale samples are then produced to cut to size for the client to verify the appearance and functionality.Adjustments to details like thickness or surface texture can be made based on feedback.

Cut To Size Acrylic Sheets

The cutting acrylic sheets process involves several techniques to achieve the desired results:

- Laser cutting ensures high precision.

- CNC routing is suitable for large-scale production.

- Heat forming allows for the creation of curved or three-dimensional structures.

Surface treatments like polishing and engraving add finishing touches, ensuring the acrylic sheets look professional and meet high-quality standards.

Packaging & Delivery

The process concludes with packaging and delivery. Protective films and shock-resistant packaging are used to ensure the safe transportation of the acrylic sheets. Installation guidelines, such as bonding methods or fixing suggestions, are provided to help achieve the best results once the acrylic sheets are delivered.

Summary

Custom acrylic sheets offer a versatile, durable, and cost-effective solution for a wide range of applications. Their superior optical properties, lightweight nature, and flexibility in design make them an ideal choice for projects that require both aesthetics and functionality.

From advertising displays to protective barriers, acrylic sheets provide a high-performance alternative to traditional materials like glass and polycarbonate.

By understanding the complete process of customizing acrylic sheets, from initial communication to final delivery, you can ensure that your project meets your exact specifications and exceeds your expectations. With the right maintenance and care, acrylic sheets can maintain their clarity and durability, providing long-lasting value. Embrace the possibilities of custom acrylic sheets and let your creative visions come to life.