Corrugated plastic sheets are a highly versatile and durable material widely utilized across multiple industries, including packaging, signage, and construction.

Known for their lightweight nature and robust performance, these sheets offer practical solutions for a variety of applications.

In this article, we will delve into the essential characteristics, advantages, and common uses of corrugated plastic sheets to provide a comprehensive understanding of why they remain a top choice in today’s market.

What Are Corrugated Plastic Sheets?

Corrugated plastic sheets are lightweight, durable plastic panels made from high-impact polypropylene resin.

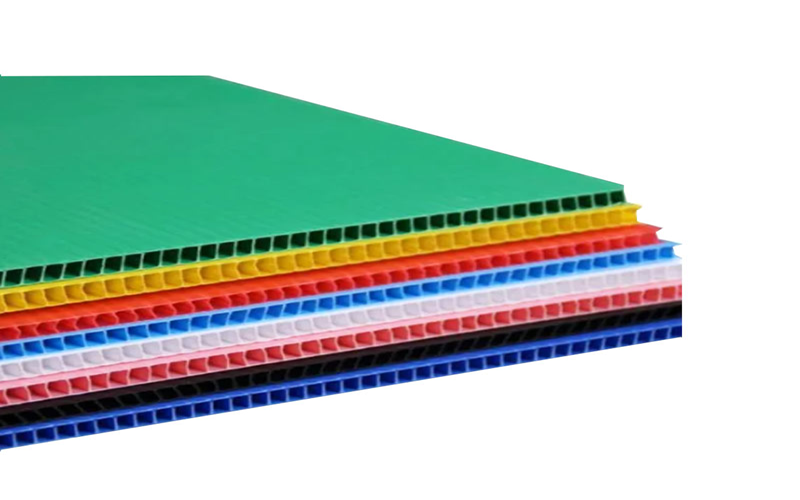

They feature a unique twin-wall structure with fluted channels between two flat plastic layers, similar in design to corrugated fiberboard but offering superior waterproof and weather-resistant properties.

Commonly used as packaging material, signage, and protective barriers, these items are manufactured to meet specific needs. In addition, the addition of special additives such as UV protection, static dissipative agents, and flame retardants during the manufacturing process enhances the features of each item for customized applications.

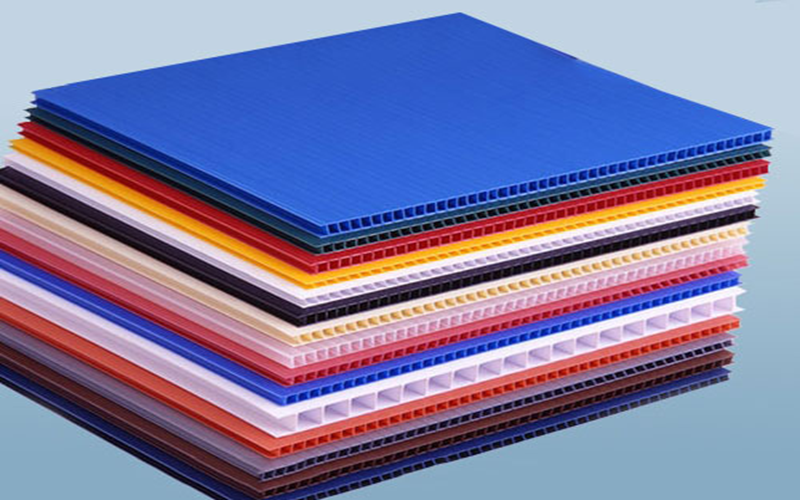

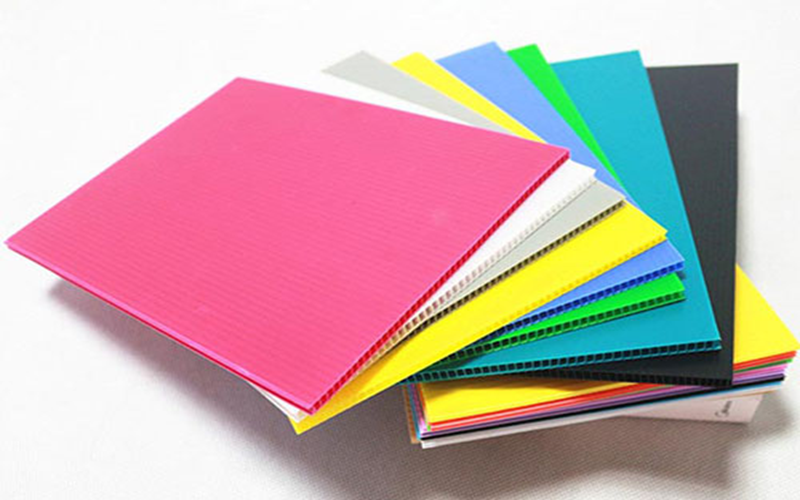

Available in various thicknesses, colors—including custom colors—and weights, corrugated plastic sheets are a popular brand choice for customers seeking long-lasting, versatile solutions where weight and ease of handling are important.

Manufacturing Process Of Corrugated Plastic Sheets

The manufacturing process of corrugated plastic sheets begins with high-impact polypropylene resin, which is melted and extruded through a specialized die to form the twin-wall structure characteristic of these sheets. This extrusion process creates two flat plastic layers connected by a series of fluted ribs, providing strength and rigidity while keeping the material lightweight.

During extrusion, various additives can be melt blended into the plastic to enhance properties such as UV resistance, flame retardancy, static dissipative capabilities, and custom coloring. These additives ensure that the finished sheets meet specific performance requirements for diverse applications.

After extrusion, the sheets are cooled and cut into standard sizes or custom dimensions according to customer specifications. Quality control measures are implemented throughout the process to ensure consistent thickness, strength, and durability.

The resulting corrugated plastic sheets are then packaged and prepared for shipment, ready to be used in industries ranging from signage and packaging to construction and display solutions.

Properties Of Corrugated Plastic Sheets

Corrugated plastic sheets possess several key properties that make them highly versatile and suitable for various applications.

These properties make corrugated plastic sheets a perfect choice for packaging material, construction protection, political and commercial signs, and many other uses.

Lightweight

These sheets have a much lower weight compared to traditional materials like corrugated fiberboard, yet they provide exceptional durability and superior resistance to impact, making them ideal for long-term use across various industries.

Their lightweight nature also contributes to easier handling, shipping, and installation, reducing overall costs and labor efforts.

Weather Resistant

The polypropylene material and twin-wall design provide superior waterproofing and protection against harsh weather conditions, making corrugated plastic sheets an ideal choice for both indoor and outdoor use.

These sheets offer excellent resistance to dirt, grease, and chemicals, ensuring long-lasting durability in various environments.

Customizable With Additives

Corrugated plastic sheets can be modified with special products that require additives such as UV protection, static dissipative agents, and flame retardants to meet specific needs and enhance performance.

These additives are melt blended into the plastic sheet during manufacturing, ensuring consistent quality and durability.

Easy To Cut

The sheets can be easily cut with standard tools such as utility knives, saws, or scissors, making them highly convenient for custom sizing and shaping to fit a wide range of project requirements.

This ease of cutting allows for precise modifications, reducing waste and saving time during installation or fabrication processes.

Recyclable

Made from polypropylene, these sheets are recyclable, supporting sustainable practices in packaging and construction industries.

Their recyclability not only helps reduce environmental impact but also aligns with increasing industry demands for eco-friendly materials.

Key Applications Of Corrugated Plastic Sheets

Corrugated plastic sheets are highly versatile and find use in a variety of industries due to their durability and lightweight properties.

Displays

Widely used for political, commercial, and real estate signs, corrugated plastic sheets provide a weather-resistant and durable surface that holds ink well, ensuring vibrant and long-lasting displays.

Their excellent adhesion qualities make them a preferred choice for outdoor signage that requires resistance to fading, dirt, and grease.

Additionally, these sheets are available in various custom colors and thicknesses, allowing customers to tailor their signs to specific branding and visibility needs.

Packaging Material

Corrugated plastic sheets serve as an excellent packaging material due to their combination of durability, lightweight design, and resistance to moisture and chemicals.

Unlike traditional cardboard, these sheets provide superior protection against dirt, grease, and water, making them ideal for shipping and storing a wide range of products.

Construction Protection

Corrugated plastic sheets are widely used in the construction industry as an effective protective barrier.

Their lightweight yet durable nature makes them ideal for shielding floors, walls, and surfaces from damage caused by dirt, grease, heavy foot traffic, and construction debris.

These sheets offer excellent waterproof and weather-resistant properties, ensuring reliable protection even in harsh outdoor environments.

How To Choose Corrugated Plastic Sheet?

Corrugated plastic sheets are available in a wide variety of types and sizes, making them a highly adaptable packaging material for countless applications.

Standard thicknesses for corrugated plastic sheets typically range from 2mm to 10mm, with 3mm, 4mm, and 6mm being the most commonly found in stock.

This range allows customers to choose the perfect sheet for their specific needs, whether they require lightweight protection or a more robust solution for demanding environments.

For projects that require enhanced performance, corrugated plastic sheets can be modified with special additives.

Note: Not all items or colors may be available in every size or configuration.

When shopping for corrugated plastic sheets, customers can easily find a wide selection of products online.

Many retailers offer the convenience of adding items to your cart, accessing special products with unique features, and choosing from a variety of sizes, colors, and thicknesses to suit your budget and requirements.

Conclusion

Corrugated plastic sheets, often referred to by the brand name Coroplast, are an incredibly versatile and durable material that offers numerous benefits across various industries.

Customers can easily cart add these sheets when shopping online, with clear pricing and product details provided on each page for convenience.

With many sheets sold in various sizes and custom colors, businesses can find the perfect solution tailored to their specific needs.

Detailed reference notes and product specifications are often included to help customers make informed decisions.

Whether used indoors or outdoors, corrugated plastic sheets deliver consistent performance, durability, and value, making them a preferred option for businesses and individuals alike.