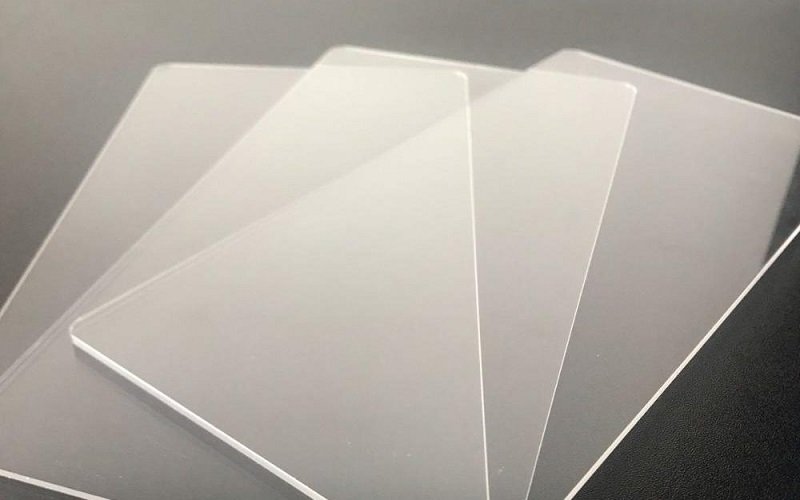

Cast acrylic sheets are highly durable and transparent plastic materials made through a casting process. Known for their strength and clarity, cast acrylic sheets are used in applications like picture frames, store displays, aquariums, and skylights.

With their proven reliability and top-notch performance, cast acrylic sheets are the ideal solution for projects where quality and appearance matter most. Customers find that these sheets consistently meet or exceed the expected standards for quality, size, and appearance.

This article will explain what cast acrylic sheets are, their key properties, and their diverse uses, particularly focusing on the benefits of using cast acrylic sheets in various industries. Whether for creative projects or industrial applications, cast acrylic sheets are just what customers need to achieve the desired results.

What Is Cast Acrylic Sheet?

Cast acrylic sheets, made from polymethyl methacrylate (PMMA), are a type of acrylic sheet produced through a casting process. This involves pouring a liquid monomer mixture into a mold, followed by heating, curing, demolding, and post-processing steps.

This method results in a product with higher transparency, superior mechanical strength, and better surface hardness compared to its extruded counterpart, including cell cast acrylic.

These sheets are incredibly versatile and easy to process, making them suitable for cutting, drill, thermoforming, and more. Their applications span a wide range of industries, including architectural decoration, advertising displays, industrial manufacturing, and top notch artistic creations.

Their versatility and superior properties make cast acrylic sheets an indispensable material in many fields. Compared to other types of glazing or decorative materials, cast acrylic sheets offer enhanced clarity, durability, and ease of fabrication, making them a preferred choice for many applications.

Cast Acrylic Sheets Manufacturing Process

The manufacturing of cast acrylic sheets is a precise and multi-step process.

First is the mold preparation, selecting high-precision glass or polished metal molds to ensure a smooth surface that guarantees the optical performance of the sheet. The mold must be cleaned and coated with a release agent (such as silicone oil), and sealed around the edges with sealing materials to control the thickness.

Next, the liquid monomer, primarily methyl methacrylate (MMA), is mixed with initiators, stabilizers, or dyes, and then poured slowly into the mold.

This step requires careful control of the pouring rate to minimize air bubbles, and sometimes vibration is used to expel any trapped air. The mold is then placed in a temperature-controlled environment, starting at 40-60°C to initiate the polymerization reaction, and gradually heated to 80-100°C for full curing. This process can take anywhere from several hours to a day.

Once curing is complete, the tested sheets are carefully demolded, and the edges are trimmed to half. Sheets can be cut to specific length and width according to customer requirements, ensuring precise dimensions and tolerances. The surfaces may be polished to enhance gloss, or annealed to remove internal stresses.

The final product is inspected for transparency, uniformity, and defects before being packaged with a protective film for shipping. This meticulous process ensures that cast acrylic sheets exhibit high transparency, uniformity, and excellent mechanical properties.

Characteristics Of Cast Acrylic Sheets

Cast acrylic sheets are renowned for their exceptional optical clarity, which rivals that of glass, allowing for high light transmission and minimal distortion.

They possess superior impact resistance, making them more durable and less prone to cracking or shattering compared to traditional glass.

Additionally, cast acrylic sheets exhibit excellent weatherability and UV resistance, ensuring they maintain their clarity and structural integrity even when exposed to prolonged sunlight and outdoor conditions.

These sheets have a higher molecular weight due to the casting process, which contributes to their enhanced mechanical strength and stability. The surface hardness of cast acrylic is also greater than that of extruded acrylic, providing better scratch resistance and longevity in demanding applications.

Cast acrylic sheets are available in a variety of thicknesses, colors, and finishes, including clear acrylic options that offer a pristine, transparent look. Their versatility extends to ease of fabrication; they can be cut, drilled, thermoformed, polished, and laser engraved with precision.

This makes them an excellent choice for custom projects, from furniture components and decorative panels to protective barriers and signage stands. Cast acrylic sheets are especially ideal for creating signage or displays that stand out and attract attention due to their visual impact and clarity.

Furthermore, cast acrylic sheets are lighter than glass—often half the weight—making them easier to handle and install without compromising strength.

Their moisture resistance and ability to withstand a wide range of temperatures add to their suitability for both indoor and outdoor use, including applications such as windows and skylights.

Overall, the combination of optical properties, durability, and versatility makes cast acrylic sheets a preferred material for many industries seeking good quality, reliable, and aesthetically pleasing solutions.

Common Applications For Cast Acrylic Sheets

Cast acrylic sheets are widely used in many industries due to their excellent properties. Beyond picture frames, store displays, aquariums, and skylights, they are also popular for creating custom furniture pieces, protective barriers, signage, and lighting fixtures.

For projects that require extra durability and strength, such as aquariums and protective barriers, thick cast acrylic sheets are often preferred because they provide added stability and resistance to impact.

Their superior optical clarity and impact resistance make them ideal for use in medical devices and optical instruments. Additionally, cast acrylic sheets are preferred in the automotive and aerospace sectors for lightweight, durable components.

Their ability to be easily cut, drilled, and formed allows designers and manufacturers to create intricate and precise creations, making cast acrylic sheets a versatile material for a wide range of projects.

Advantages Of Cast Acrylic Sheet

The advantages of cast acrylic sheets are numerous, including exceptional optical performance with light transmittance exceeding 92%, making them nearly as clear as glass and ideal for optical and display applications.

They offer high durability with strong impact resistance and UV stability, ensuring they do not yellow or degrade even after prolonged sunlight exposure.

Additionally, cast acrylic sheets are versatile and easy to process—they can be cut, drilled, thermoformed, bonded, and polished to meet complex design and customization needs.

Available in a wide range of colors such as white, blue, green, and purple, as well as various thicknesses and sizes, these sheets can also incorporate functional materials like antibacterial or antistatic properties, making them suitable for a variety of specialized applications and more.

Disadvantages Of Cast Acrylic Sheet

Despite their many benefits, cast acrylic sheets have some disadvantages:

- Higher cost: Compared to extruded acrylic sheets, the casting process is more complex, resulting in higher production costs and a more expensive price.

- Longer production cycle: The casting and curing process takes a significant amount of time (several hours to a full day), making it unsuitable for large-scale rapid production.

- Scratch sensitivity: Although the surface hardness is higher, cast acrylic sheets are still prone to scratches from sharp objects and require surface protection or careful handling.

- Heat sensitivity: They soften and deform easily under high temperatures, with limited heat resistance (generally around 80-100°C).

What Are The Difference Between Cast Acrylic Sheet And Extruded Acrylic Sheet?

The differences between cast acrylic sheets and extruded acrylic sheets are significant. Cast acrylic sheets are made by pouring liquid monomer into molds, followed by a curing process that takes several hours to a day.

This method allows for customization in terms of thickness, color, and functional properties like UV resistance.

Extruded acrylic sheets, on the other hand, are produced by continuously extruding molten PMMA resin through a die, resulting in a more uniform thickness but fewer customization options. This process is faster and more cost-effective, making extruded acrylic sheets less expensive than their cast counterparts.

In terms of performance, cast acrylic sheets offer several advantages over extruded acrylic sheets:

- Higher molecular weight and lower internal stress, making them more suitable for precision machining and complex designs

- Superior optical clarity

- Higher surface hardness

- Better resistance to chemicals and impact

While extruded acrylic sheets are more prone to scratching and have lower thermal stability, they are widely used for applications with less stringent requirements due to their lower cost.

Customization Options For Cast Acrylic Sheets

One of the standout features of cast acrylic sheets is their remarkable versatility in customization. Whether you need a clear cast acrylic sheet for maximum transparency or a vibrant colored sheet to make your project pop, there’s a wide range of options to choose from.

Cast acrylic sheets are available in a variety of colors, including classic clear, bold blue, striking red, sunny yellow, lush green, and even eye-catching purple. This extensive palette allows you to match your design vision perfectly, whether for picture frames, store displays, or custom furniture.

Beyond color, cast acrylic sheets can be ordered in different thicknesses, sizes, and finishes to suit your specific requirements.

Sheets can be cut to precise lengths and widths, drilled for mounting, or formed into unique shapes for creative projects. Advanced fabrication techniques like laser cutting and engraving make it easy to add intricate details, logos, or patterns, giving your creations a professional, custom look.

These customization options make cast acrylic sheets an ideal choice for a wide range of applications, from outdoor signage and architectural features to decorative panels and retail displays. Despite their premium appearance and performance, cast acrylic sheets are generally considered a cost-effective option, with prices varying based on thickness, size, and color.

Whether you’re working on a one-of-a-kind art piece or outfitting a commercial space, cast acrylic sheets offer the flexibility, durability, and optical clarity needed to bring your ideas to life.

How To Choose And Use Cast Acrylic Sheet?

Choosing and using cast acrylic sheets requires careful consideration of the specific needs and application scenarios.

The first step is to select the appropriate type of cast acrylic sheet based on thickness, color, and any special functional requirements like UV resistance or antibacterial properties.

For high-clarity applications like optical instruments, clear cast acrylic sheets are ideal, while colored or translucent sheets may be better for decorative purposes.

Processing techniques are crucial for achieving the desired results with cast acrylic sheets. For cutting, laser cutting is recommended for its precision and smooth edges, while saw cutting and manual cutting are suitable for thicker or simpler shapes.

Thermoforming involves heating the sheet to 120-160°C and shaping it over a mold, with cooling required to maintain the formed shape. Polishing can be done using flame, mechanical, or chemical methods depending on the complexity and finish required.

When using cast acrylic sheets, keep the following precautions in mind:

- Avoid exposing them to high temperatures to prevent softening and deformation.

- Protect the surface from scratches by retaining the protective film until installation.

- Use gentle cleaning methods to maintain the surface quality.

For structural applications, consider the impact resistance and load-bearing capabilities, and ensure proper support to prevent bending or breaking. Proper storage and transportation, keeping the sheets flat and protected from sharp objects, will help maintain their quality.

Summary

Cast acrylic sheets are a remarkable material combining the clarity of glass with the durability and versatility of plastic. Their manufacturing process, though intricate, results in a product with superior optical and mechanical properties.

Whether used in picture frames, store displays, or large-scale applications like aquariums and skylights, cast acrylic sheets prove to be an excellent choice.

While they come with some disadvantages, such as higher cost and sensitivity to scratches, their benefits often outweigh these drawbacks.

Understanding the differences between cast and extruded acrylic sheets and knowing how to choose and use cast acrylic sheets effectively can help you make informed decisions for your projects. Embrace the potential of cast acrylic sheets and let their unique properties enhance your creations.