In industries where precision and safety are paramount, static electricity can pose a significant threat to sensitive components and processes.

Anti static plastic sheets have become an essential solution, designed to prevent or dissipate electrostatic discharge (ESD) that could damage electronics or ignite flammable environments.

This article introduces the fundamentals of anti static plastic sheets, exploring their composition, benefits, and wide-ranging applications in sectors like electronics, manufacturing, and aerospace.

What Is Anti Static Plastic Sheet?

An anti static plastic sheet is a specialized type of plastic sheeting engineered to significantly reduce or completely eliminate the buildup of static electricity on its surface.

These sheets are often described as electrostatic dissipative materials because they are designed to safely dissipate static charges, preventing harmful electrostatic discharge (ESD).

These sheets are typically manufactured from durable plastics such as polyethylene, polycarbonate, or acrylic, and are enhanced with permanent anti-static coatings.

The anti static plastic sheet offers superior impact resistance and chemical resistance, and is both hard and strong, ensuring toughness and reliability for demanding industrial applications. This makes it highly suitable for a wide range of industrial applications including static control shields, glove boxes, conveyor line covers, access panels, doors, and windows.

Key Properties Of Anti Static Plastic Sheet

The key properties of anti static plastic sheets make them highly effective in preventing static electricity buildup and electrostatic discharge (ESD).

Surface Resistivity

Surface resistivity is a critical property of anti static plastic sheets, measuring their ability to dissipate static electricity safely.

Typically expressed in ohms per square, these sheets exhibit surface resistivity values ranging from 10^6 to 10^8 ohms per square.

Moreover, the surface resistivity of these sheets remains stable and unaffected by changes in humidity, guaranteeing consistent performance on electrically conductive surfaces and in various environmental conditions.

Durability

Durability is a crucial factor when selecting an anti static plastic sheet, especially for industrial and manufacturing applications.

This robust construction ensures that the sheets maintain their protective properties and structural integrity even under harsh conditions, including frequent handling and exposure to abrasive environments.

Additionally, the long-lasting nature of these materials means that anti static plastic sheets can be used repeatedly without significant degradation, offering cost-effective and reliable static control solutions for various industries.

Transparency

Transparency is a vital characteristic of many anti static plastic sheets, especially in applications where visual clarity is essential.

These sheets offer excellent optical clarity, allowing for clear visibility while still providing effective protection against static electricity and electrostatic discharge (ESD).

This makes them ideal for use in protective windows, display cases, and equipment covers where monitoring or visual inspection is necessary without compromising safety.

Compatibility With Electrically Conductive Surfaces

Anti static plastic sheets are specifically designed to work seamlessly with electrically conductive surfaces, enhancing their ability to control and dissipate static electricity.

This compatibility is crucial in environments where sensitive electronic components are handled, as it ensures that static electricity is safely directed away, reducing the risk of electrostatic discharge (ESD) damage.

By integrating anti static plastic sheets with electrically conductive surfaces, manufacturers can achieve superior protection against static-related issues while maintaining durability and chemical resistance.

Types Of Anti Static Plastic Sheets

Anti static plastic sheets come in various types, each tailored to specific applications and performance requirements.

Each type of anti static plastic sheet is designed to control static electricity effectively while offering unique benefits related to durability, clarity, and fabrication ease.

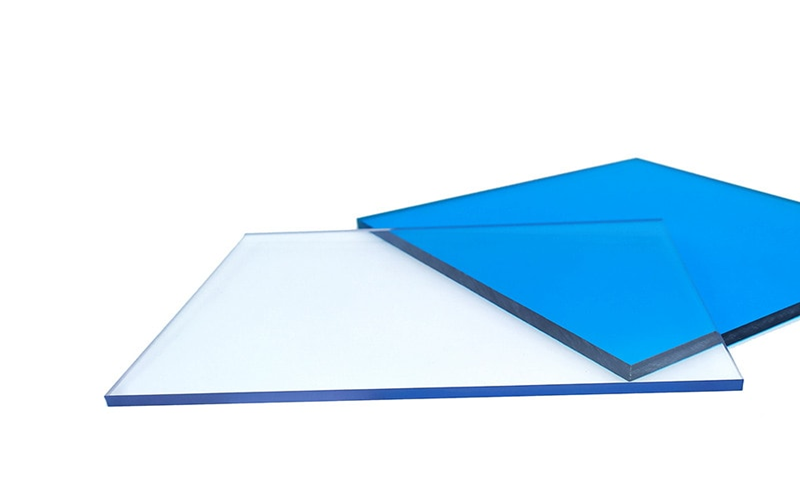

Anti Static Polycarbonate Sheet

Known for their superior impact resistance and durability, these sheets are often coated with permanent anti-static layers that remain effective regardless of humidity or environmental changes.

This makes them highly reliable for long-term use in critical applications.

They are ideal for environments requiring clear visibility and robust protection, such as protective windows, access panels, and static control shields.

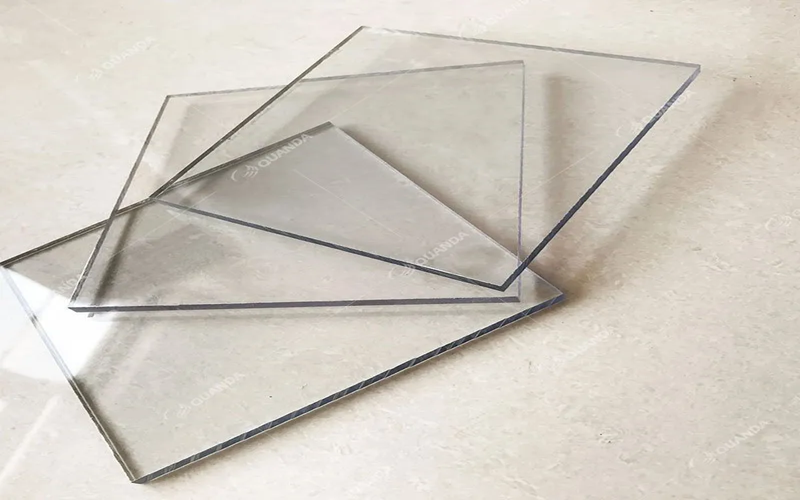

Anti Static Acrylic Sheeting

Acrylic sheets offer excellent optical clarity and outstanding chemical resistance, making them highly suitable for applications such as display cases, glove boxes, and protective covers for electronic equipment.

Their durable anti-static coating effectively prevents dust attraction and minimizes the risk of electrostatic discharge (ESD).

Additionally, acrylic sheeting is easy to fabricate and maintain, providing a reliable and cost-effective solution for static control needs.

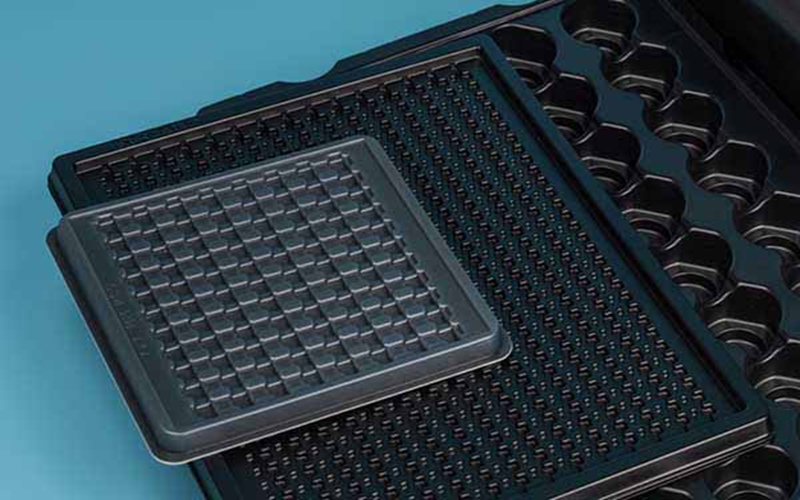

Anti Static PETG Sheet

PETG sheets provide an excellent balance between flexibility and strength, combined with effective static dissipative properties.

These sheets are highly valued for their ease of fabrication and thermoforming capabilities, making them ideal for applications such as conveyor line covers, protective barriers, and other custom-shaped static control shields.

PETG anti static plastic sheets are also compatible with electrically conductive surfaces, enhancing their effectiveness in preventing electrostatic discharge (ESD) in sensitive manufacturing and electronic equipment settings.

Applications Of Anti Static Plastic Sheets

Anti static plastic sheets are widely used across various industries due to their ability to prevent static electricity buildup and protect sensitive components.

Electronics Manufacturing

In the electronics manufacturing industry, anti static plastic sheets play a crucial role in protecting sensitive electronic components from electrostatic discharge (ESD).

These sheets are commonly used as static control shields, glove boxes, and conveyor line covers, creating a controlled environment that minimizes static charge buildup.

By effectively dissipating static electricity, anti static plastic sheets help prevent damage to delicate microchips and circuit boards, reducing product defects and improving overall manufacturing yield.

Medical Equipment

Anti static plastic sheets play a vital role in the medical equipment industry by providing a clean, safe, and static-free environment for sensitive devices.

These sheets help prevent electrostatic discharge (ESD) that can damage delicate electronic components in diagnostic machines, monitoring systems, and surgical instruments.

Their excellent chemical resistance and durability ensure long-lasting protection against frequent cleaning and sterilization processes.

Aerospace

In the aerospace industry, anti static plastic sheets play a critical role in protecting sensitive electronic systems and components from electrostatic discharge (ESD) that could compromise safety and functionality.

These sheets are used in aircraft interiors, control panels, and electronic enclosures to ensure stable performance under varying environmental conditions, including changes in humidity and temperature.

Their superior impact resistance and chemical durability make them ideal for withstanding the demanding conditions of aerospace applications.

Industrial Environments

In industrial environments, controlling static electricity is critical to ensure both safety and operational efficiency.

Anti static plastic sheets are widely used in these settings as protective covers and enclosures for machinery and equipment, preventing electrostatic discharge (ESD) that could lead to equipment malfunctions or even fire hazards.

These sheets are designed to withstand harsh conditions commonly found in industrial facilities, including exposure to chemicals, abrasion, and varying humidity levels.

Additionally, by integrating anti static plastic sheets into conveyor line covers, access panels, and static control shields, industries can effectively reduce the risk.

How To Choose The Right Anti Static Plastic Sheet?

Choosing the right anti static plastic sheet is essential to ensure optimal protection against static electricity and electrostatic discharge (ESD) in your specific application.

Start by assessing the sensitivity of the electronic components or equipment involved, as this determines the required level of surface resistivity and static dissipative properties.

Additionally, evaluate the material type—polycarbonate, acrylic, or PETG—based on the balance of impact resistance, chemical resistance, and optical clarity needed.

Cost-effectiveness and availability, such as stock options and roll sizes, should also be factored in to ensure the sheet meets budget and logistical needs. Anti static plastic sheets are often available in rolls, which can be convenient for large-scale or industrial applications.

Finally, purchasing from a reputable website or supplier that offers reliable shipping and customer support can enhance the overall experience and guarantee product quality. For example, companies like A&C Plastics or Boedeker Plastics are well-known suppliers in the industry.

Maintaining And Handling Anti Static Plastic Sheets

Maintaining anti-static plastic sheets is essential to ensure their longevity and effectiveness. Avoid using harsh chemicals and abrasive cleaners, as these can damage the surface and diminish the anti-static properties.

Instead, clean the sheets by rubbing them with a soft, lint-free cloth or sponge to preserve their surface integrity.

Regular inspection of the sheets for signs of wear or damage is crucial. This ensures that any issues are identified and addressed promptly, maintaining the sheet’s optimal performance.

Proper storage is also important. Keeping the sheets in a cool, dry environment away from direct sunlight can prevent warping or deformation and allow them to rest properly.

During transport or storage, using protective covers can safeguard the sheets from scratches and external damage.

Following these maintenance and handling guidelines ensures that anti-static plastic sheets remain effective and reliable over time.

Summary

Anti-static plastic sheets are invaluable in protecting sensitive electronic components from the damaging effects of static electricity.

As industries continue to evolve and technology advances, the demand for reliable ESD protection will only increase.

Every person involved in manufacturing or handling electronic equipment can benefit from the enhanced safety these anti static plastic sheets offer.

Before making a purchase, it is advisable to review product specifications and customer feedback to ensure the chosen anti static plastic sheet meets your specific application requirements.

These anti static plastic sheets are usually available in various roll sizes, making it convenient for businesses to shop and order the quantity that best fits their needs.

Once ordered, the sheets are carefully shipped to ensure they arrive in optimal condition, unaffected by environmental factors during transit.

Additionally, anti static plastic film options are available for applications requiring flexible and lightweight static control solutions.

Finally, proper selection and handling help prevent the sheets from being adversely affected by environmental conditions, ensuring long-lasting performance and reliability.

Frequently Asked Questions

What Are Prevent Static Electricity Plastic Sheets Made Of?

Anti-static plastic sheets are primarily composed of polyethylene and are treated with anti-static coatings to ensure effective electrostatic discharge (ESD) protection.

How Do Anti Static Plastic Sheets Prevent Electrostatic Discharge?

Anti-static plastic sheets effectively prevent electrostatic discharge by minimizing static electricity build-up and dissipating any accumulated charges. This functionality is crucial for protecting sensitive electronic components.

What Factors Should I Consider When Choosing An Anti Static Plastic Sheet?

When choosing an anti-static plastic sheet, it is crucial to evaluate the sensitivity of the electronic components, environmental conditions, cost-effectiveness, and material transparency to ensure optimal protection and functionality. In addition, take into account the availability of different roll sizes and stock options from suppliers, as this can affect your purchasing decisions and project requirements.

How Should I Maintain And Handle Anti Static Plastic Sheets?

To maintain and handle anti-static plastic sheets effectively, clean them with a soft cloth and avoid harsh chemicals. Regularly inspect for damage, and store them in a cool, dry place using protective covers during transport. This will ensure their longevity and effectiveness.

What Are The Different Types Of Anti Static Plastic Sheets?

The primary types of anti-static plastic sheets are anti-static polycarbonate, acrylic, and PETG sheets, each designed for specific applications due to their unique properties. Selecting the appropriate type is crucial for ensuring optimal performance in static-sensitive environments.