Acrylic and polycarbonate sheets are versatile thermoplastic materials widely used in modern industry and daily life.

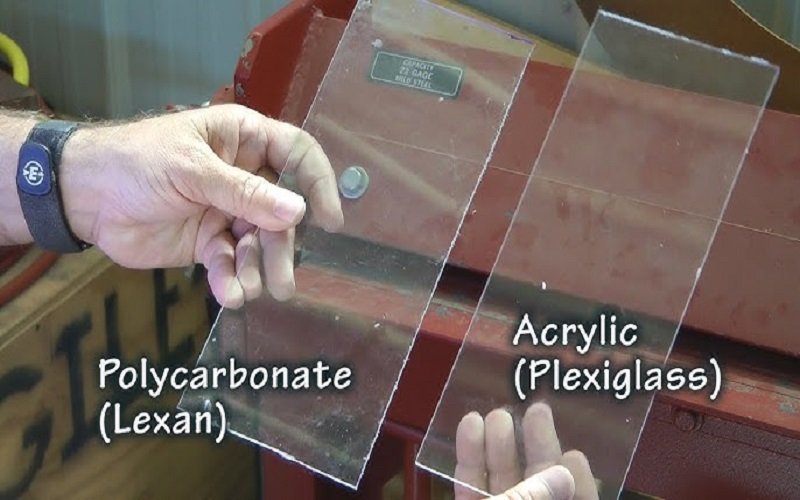

Acrylic, known for its glass-like clarity and ease of processing, is common in signage, displays, and decorative applications, while polycarbonate, prized for its exceptional strength and impact resistance, is favored in safety glazing, protective shields, and architectural roofing.

This article aims to clarify the distinctions between these materials, highlighting their properties, applications, and trade-offs to guide readers in selecting the most suitable option for their specific needs.

What Is Acrylic Sheet?

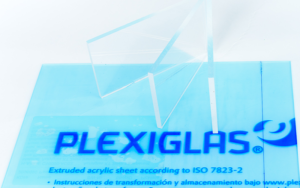

Acrylic, often referred to as PMMA (Polymethyl Methacrylate), is a synthetic polymer known for its remarkable clarity and versatility. This acrylic plastic material is produced by polymerizing methyl methacrylate monomers, resulting in a transparent or colored thermoplastic that can be formed into various shapes and sizes.

Acrylic sheets have earned the nickname “plastic queen” due to their aesthetic appeal and excellent properties.

Cast acrylic is made by pouring the monomer and catalyst into molds, where the mixture is cured to form sheets of various sizes and thicknesses. During the chemical synthesis of the methyl methacrylate monomer, methyl alcohol (methanol) is used as a key reactant. The use of molds allows for precise control over the final product, and cast acrylic is valued for its clarity, affordability, and ease of fabrication.

Acrylic sheets boast a transparency rate of over 92%, providing a crystal-clear view that rivals even the finest glass. Their excellent weather resistance makes them ideal for outdoor use, while their ease of fabrication allows for a wide range of applications.

Acrylic can be shaped easily by heating, making it suitable for custom shapes, curved designs, and a variety of profiles.

What Is Polycarbonate Sheet?

Polycarbonate sheets, also known as PC sheets, are made from a high-performance thermoplastic polymer known as polycarbonate. These sheets are produced using a co-extrusion process, which enhances their strength and durability.

Notably, polycarbonate sheeting is available in a range of flexible grades thermoplastic, suitable for demanding applications. Polycarbonate sheets exhibit a high impact resistance, making them suitable for applications where safety is a priority.

Polycarbonate is also highly resistant to chemicals such as gasoline and other solvents, making it a preferred choice in industrial environments. Unlike acrylic, polycarbonate can be shaped at room temperature through cold forming without cracking, allowing for versatile fabrication options.

Additionally, polycarbonate sheets are non flammable highly resistant and maintain their structural integrity even when exposed to high temperatures, which broadens their applicability in environments subject to heat or flame exposure.

The manufacturing processes for polycarbonate involve extrusion and molding techniques that allow for a variety of thicknesses and finishes, including clear, tinted, and mirrored surfaces. This versatility enables polycarbonate to be used in everything from bullet resistant grades to abrasion-resistant panels.

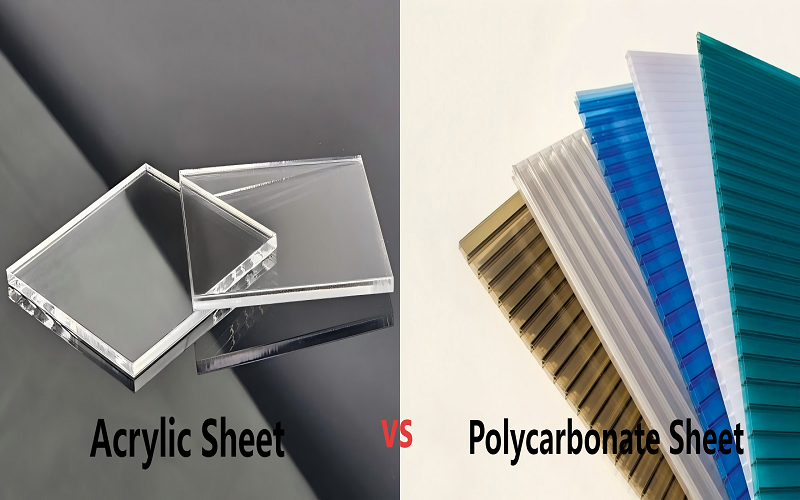

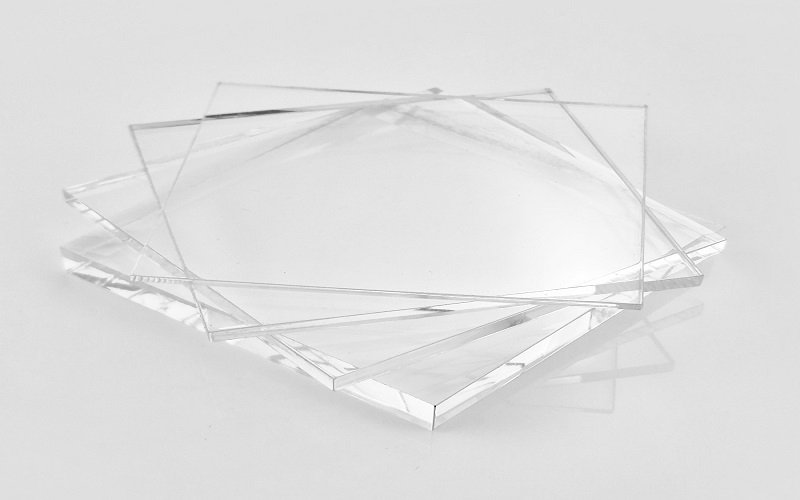

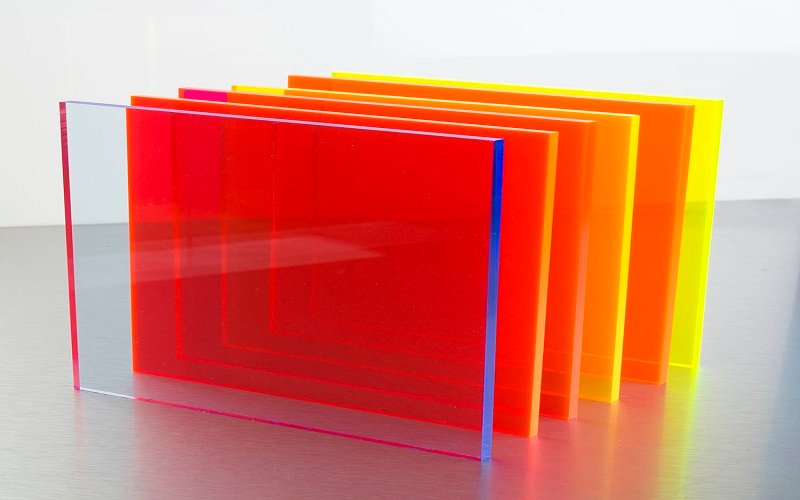

Types Of Acrylic And Polycarbonate Sheets

Acrylic and polycarbonate sheets are available in a wide array of types and forms, making them adaptable to nearly any project requirement.

Polycarbonate sheets can be found in clear, colored, and mirrored varieties, as well as in specialized grades such as bullet resistant, abrasion resistant, and flame-retardant options.

These advanced forms of polycarbonate and acrylic sheeting are engineered to meet the demands of environments where impact resistance, safety, or fire performance are critical.

Acrylic sheets, renowned for their high clarity, are a popular choice for display cases, signage, and other applications where transparency and visual appeal are essential.

Both acrylic and polycarbonate materials can be manufactured with additional features like UV resistance, anti-static properties, and scratch-resistant coatings, enhancing their suitability for outdoor installations, cleanroom environments, or high-traffic areas.

The versatility of acrylic and polycarbonate sheets extends to their dimensions and fabrication possibilities. Available in a range of thicknesses, widths, and lengths, these materials can be cut, drilled, and shaped to fit the needs of a specific project.

Acrylic sheet can be heated and molded into complex shapes without losing its optical clarity, while polycarbonate sheets can be cold-formed for curved or contoured applications.

This flexibility allows both materials to be used in everything from architectural glazing and protective barriers to creative design elements and industrial components.

Acrylic vs Polycarbonate : Properties

When comparing acrylic sheets and polycarbonate sheets, several key differences in their properties stand out, influencing their suitability for various uses.

Strength and Durability

Polycarbonate sheets lead in strength and durability, with impact resistance 250 times better than glass and 30 times more effective than acrylic. Polycarbonate is regarded as the stronger material when maximum impact resistance is required.

This makes them ideal for applications where safety and durability are paramount, such as in protective shields and security glazing.

On the other hand, acrylic sheets, while also durable, are not as impact-resistant as polycarbonate. They are, however, 16 times stronger than standard glass, making them a reliable option for less demanding applications, and they offer greater strength than acrylic.

Consider the required level of impact resistance for your specific use case when choosing between these materials.

Weight and Flexibility

Significantly lighter than traditional glass, both acrylic and polycarbonate sheets are easier to handle and install. Acrylic sheets are particularly lightweight, weighing approximately half as much as glass, which simplifies transportation and installation.

Polycarbonate sheets, while also lightweight, generally have a slightly higher weight than comparable acrylic sheets of the same thickness. This difference in weight can affect handling and installation, especially in larger projects.

Polycarbonate sheets offer greater flexibility. This flexibility makes them suitable for applications requiring curved designs or where the material needs to be bent without breaking. These properties can be particularly advantageous in architectural and design projects where innovative shapes are desired, including the use of polycarbonate plastic sheeting.

Clarity and Appearance

Acrylic sheets are notable for their superior clarity and aesthetic appeal. They offer a transparency rate of over 92%, providing a crystal-clear view that is unmatched by other materials.

This makes acrylic the go-to choice for applications where visual clarity and appearance are critical, such as in display cases and signage.

Polycarbonate sheets, with a transparency rate of up to 89%, also offer good optical clarity and better clarity. However, over time, polycarbonate tends to become more translucent, whereas acrylic retains its clarity and gloss. For projects where long-term visual clarity is important, acrylic may be the better choice.

Surface Damage Resistance

Surface damage resistance is crucial. Polycarbonate sheets are highly resistant to scratches and cracks highly resistant, which makes them ideal for high-traffic areas and applications where the material is subject to frequent handling. Polycarbonate is also less likely to be dented easily compared to acrylic, which is more prone to denting and cracking upon impact. However, polycarbonate is more prone to chipping upon impact compared to acrylic.

Acrylic sheets, while less resistant to scratches, do not chip as easily as polycarbonate. Acrylic may be preferable for applications where surface appearance is crucial and scratching is less likely. The choice between these materials should consider the specific conditions and potential for surface damage.

UV Resistance and Weather Durability

Acrylic sheets are excellent in UV resistance, flammability durable, and weather durability. They can withstand prolonged exposure to sunlight, wind, and rain without significant degradation in performance or appearance. This makes them ideal for outdoor applications such as skylights and signage.

Polycarbonate sheets, while durable, require a UV protective coating to prevent yellowing and brittleness when exposed to UV rays. For long-term outdoor use, the additional maintenance of polycarbonate sheets should be considered. If UV resistance and weather durability are critical, acrylic may offer a more straightforward solution.

Cost Considerations

Cost plays a significant role in material selection. Acrylic sheets are generally less expensive than polycarbonate, typically costing 20-30% less, making them a cost-effective option for budget-conscious projects.

While acrylic offers superior clarity and ease of fabrication, polycarbonate sheets justify their higher price with exceptional strength, impact resistance, and durability, making them ideal for demanding applications where safety is paramount.

Choosing between these two materials depends on balancing budget constraints with performance needs, as acrylic provides better clarity and affordability, whereas polycarbonate excels in toughness and long-term resilience.

| Performance Metric | Acrylic Sheet | PC Sheet (Polycarbonate) |

|---|---|---|

| Density | 1.18 g/cm³ | 1.20 g/cm³ |

| Transparency | 92%-93% | 85%-90% |

| Impact Strength | Approximately 16 times that of standard glass | Approximately 250 times that of standard glass |

| Scratch Resistance | Good, can be polished to restore | Prone to scratching, requires protective coating |

| UV Resistance | Excellent, naturally UV resistant | Requires UV protective coating |

| Heat Resistance | Around 80°C | Around 120°C |

| Processing | Easy to cut, thermoform, and bond | More difficult to process, good for cold forming |

| Chemical Resistance | Good acid resistance, sensitive to solvents | Resistant to gasoline and various chemicals |

| Weight | Lighter | Slightly heavier |

Processing Methods For Acrylic And PC Sheets: Key Differences

Acrylic sheets and polycarbonate sheets differ significantly in processing methods due to their material characteristics.

Acrylic is hard and brittle, allowing clean cuts via laser or saw, and is suitable for heat forming (100-160°C) to fix shapes. It is generally easier to machine than polycarbonate, making it a popular choice for custom sub-bases and work surfaces. It bonds well with solvents, resulting in transparent seams, and can be polished to a high gloss.

Acrylic is easy to process and cost-effective, making it ideal for applications with high aesthetic demands. However, lighter sheets of acrylic are more susceptible to cracking, especially during handling or installation. When drilling or upon impact, acrylic is more prone to cracking compared to polycarbonate, which offers greater impact resistance and durability.

Polycarbonate, on the other hand, is tough and requires high-speed saws or CNC cutting with cooling to prevent burrs. It can be cold bent or heat formed (130-190°C), and unlike acrylic, polycarbonate can be bent without cracking, while acrylic is more prone to cracking when cold formed.

In addition, bonding polycarbonate sheets is more complex, requiring specific adhesives such as glue bonding shinier, and the bonding strength may not be as strong as that of acrylic.

Polishing results are limited and often rely on coatings to enhance gloss. Installation is flexible but requires attention to UV coating orientation. Processing polycarbonate is more challenging and costly, suited for high-strength applications.

Uses For Acrylic and Polycarbonate Sheet

Acrylic and polycarbonate sheets are versatile plastic materials used across various industries, including polycarbonate and acrylic sheets.

Their applications range from architectural elements to safety features, showcasing their adaptability and functional benefits. Choosing acrylic or polycarbonate depends on the specific needs of the application.Exploring the typical uses of each material helps understand their practical applications better.

Application Of Acrylic Sheets

Due to their excellent clarity and ease of fabrication, acrylic sheets are widely used in display cases, signage, and furniture. Acrylic is also referred to as plexiglass sheeting in many industries and is used in similar applications.

Retail environments, in particular, favor acrylic for its aesthetic appeal and ability to showcase products effectively. Its versatility allows it to be easily shaped and colored, making it suitable for various design applications.

Solvent welding, break forming, and flame polishing are common fabrication techniques for acrylic sheets, enabling intricate designs and smooth finishes. Continuous production processes allow for larger sheets, making acrylic an efficient choice for industrial applications.

Application Of Polycarbonate Sheets

Due to their high impact resistance and durability, pc sheets are commonly used in safety windows, automotive parts, and protective barriers, including resistant windows.

Applications requiring bullet resistant properties, like security glazing, rely on polycarbonate for its superior strength.

When comparing materials for security glazing and protective barriers, both polycarbonate and acrylic bullet resistant grades are considered, but polycarbonate is generally preferred for higher impact resistance and durability. The material’s resilience makes it ideal for protective screens, enclosures, and equipment in demanding environments.

Polycarbonate’s optical clarity also makes it suitable for eyewear lenses and other applications where clear visibility is essential. Its ability to withstand high impacts and maintain durability under stress highlights its importance in safety-critical applications.

How To Choose Between Polycarbonate And Acrylic?

When selecting between acrylic and pc sheets, align your choice with specific application needs.

For projects prioritizing aesthetics and transparency, such as display cases or signage, acrylic is preferred due to its superior clarity (92%+ light transmission) and glossy finish.

For applications demanding strength and safety, like protective shields or security glazing, polycarbonate is ideal, offering impact resistance 250 times that of glass. Budget constraints favor acrylic, which is typically 20-30% cheaper than polycarbonate.

For long-term outdoor use, such as roofing or canopies, consider durability and maintenance costs: acrylic naturally resists UV degradation, while polycarbonate requires a UV coating to prevent yellowing. Environmental factors, including temperature (acrylic withstands up to ~80°C, polycarbonate up to ~120°C), chemical exposure (acrylic resists acids but not solvents; polycarbonate resists solvents but not strong alkalis), and UV exposure, also guide the decision.

Processing and installation capabilities matter too—acrylic is easier to cut, polish, and bond, suiting simpler equipment, while polycarbonate’s toughness demands advanced tools and expertise.

For example, in choosing a material for architectural skylights, acrylic may be selected for its clarity and cost-effectiveness in mild climates with minimal impact risk, but polycarbonate is better for high-traffic areas or regions with extreme weather due to its durability and flexibility, provided UV protection and higher costs are addressed. Evaluate these factors to ensure the material meets both functional and economic needs.