Choosing the right acrylic sheet thickness is essential for ensuring your project is both functional and visually appealing.

Whether you’re working on furniture, protective barriers, outdoor signage, or custom artwork, selecting the appropriate thickness affects the durability, strength, and flexibility of your acrylic sheets.

In this guide, we’ll explore how to choose the perfect acrylic sheet thickness to meet your project’s specific needs, helping you achieve a sturdy, polished, and professional result every time.

What Is Acrylic Sheet?

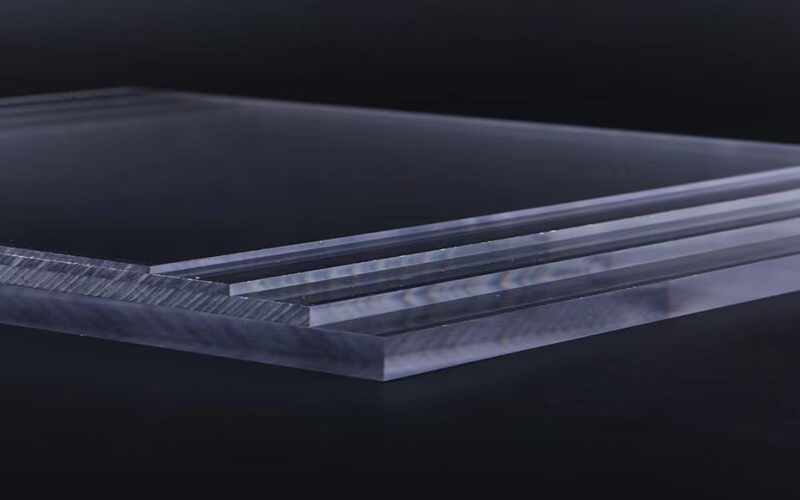

Acrylic sheet is a versatile, durable plastic material widely used as a lightweight and impact-resistant alternative to glass.

Acrylic sheets are typically clear but can also be found in various colors and thicknesses, measured in inches or millimeters, to suit different needs.

Their surface is smooth and resistant to scratches, and they weigh about half the weight of glass, offering excellent rigidity and durability.

With options for custom dimensions, radius corners, and edge finishes, acrylic sheets provide a practical and aesthetic solution for a wide range of applications.

Types Of Acrylic Sheets

When selecting acrylic sheets for your project, it’s important to understand the different types available to ensure you choose the most suitable option.

Cast Acrylic Sheet

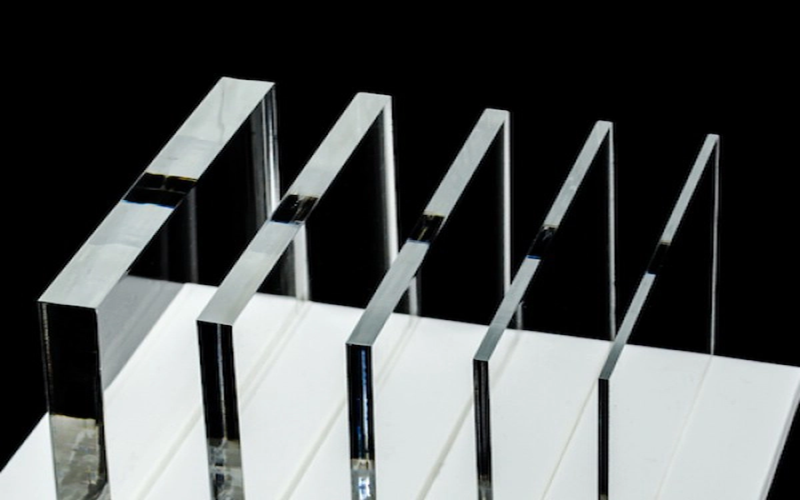

Cast acrylic sheets are produced by pouring liquid acrylic into molds, resulting in a thicker, more rigid, and premium-quality material compared to extruded sheets.

Known for their superior impact resistance and excellent optical clarity, cast acrylic sheets are ideal for applications requiring durability and a polished appearance, such as high-end furniture, display cases, and artwork protection.

These sheets offer greater dimensional stability and better suitability for drilling, cutting, and laser engraving, making them a preferred choice for custom projects.

Extruded Acrylic Sheet

Extruded acrylic sheets are manufactured by continuously pushing acrylic material through a form or die, resulting in a more cost-effective and lightweight option compared to cast acrylic sheets.

These sheets are known for their consistent thickness and smooth surface, making them suitable for applications where budget and ease of fabrication are priorities.

They are also easier to cut, drill, and shape, making them a popular choice for customers seeking custom cut-to-size acrylic sheets with precise width, length, and shape specifications.

Clear Acrylic Sheet

Clear acrylic sheets are prized for their exceptional transparency and clarity, offering a glass-like appearance while being much lighter and more impact resistant.

These sheets are an ideal choice for projects where visibility and light transmission are crucial, such as display cases, windows, protective barriers, and signage.

Their smooth surface resists scratches and can be easily cleaned, maintaining their pristine look over time.

Colored Acrylic Sheet

Colored acrylic sheets offer a vibrant and versatile option for projects that require both functionality and aesthetic appeal.

Available in a wide range of hues and finishes—including translucent, opaque, and frosted—these sheets allow you to customize your design while maintaining the durability and impact resistance typical of acrylic.

Colored acrylic is ideal for applications such as signage, decorative panels, furniture accents, and privacy screens.

Factors Influencing Acrylic Sheet Thickness Selection

When deciding on the appropriate acrylic sheet thickness for your project, several key factors come into play.

Load Bearing Requirements

Understanding the load bearing requirements is crucial when selecting the right acrylic sheet thickness for your project.

Acrylic sheets that need to support significant weight, such as shelving, furniture, or protective barriers, should be thicker to ensure they provide the necessary strength and durability.

Thicker sheets can withstand heavier loads without sagging or cracking, offering long-lasting support and maintaining the structural integrity of your project.

Impact Resistance

Impact resistance is a critical factor when choosing the right acrylic sheet thickness for your project.

Thicker acrylic sheets provide superior resistance to impacts, making them less likely to crack, chip, or break under stress.

For example, cast plexiglass sheets are known for their excellent impact resistance compared to extruded sheets, offering enhanced protection and longevity.

Flexibility Needs

When considering acrylic sheet thickness, flexibility plays a vital role depending on your project’s requirements.

Thinner acrylic sheets, typically ranging from 1/16″ to 1/8″ (1.5 mm to 3 mm), offer excellent flexibility, allowing you to bend, curve, or shape the material easily without cracking.

On the other hand, thicker sheets provide more rigidity and structural support but are less suited for bending.

Common Acrylic Sheet Thickness Ranges

Thin Sheets (1mm–3mm)

Thin acrylic sheets, typically ranging from 1mm to 3mm in thickness, are ideal for projects that require flexibility and lightweight materials.

These sheets are easy to cut, shape, and bend, making them perfect for applications such as small photo frames, indoor signs, craft projects, and decorative panels.

When ordering thin acrylic sheets, it is important to consider the tolerances and minimum thickness requirements to ensure accurate dimensions and optimal performance for your project.

Medium Sheets (4mm–10mm)

Medium thickness acrylic sheets, ranging from 4mm to 10mm, offer an excellent balance between strength and flexibility, making them suitable for a wide variety of applications.

These sheets provide enhanced durability and impact resistance compared to thinner options, while still allowing some degree of shaping and customization.

Ideal for protective barriers, display cases, furniture panels, and signage, medium sheets ensure sturdy support without excessive weight.

Thick Sheets (12mm and Above)

Thick acrylic sheets, measuring 12mm and above, are designed for heavy-duty applications that demand maximum strength, rigidity, and durability.

These sheets are ideal for projects such as structural furniture components, large protective barriers, countertops, and architectural installations where robust support is essential.

When ordering thick acrylic sheets, precise cut-to-size services and accurate dimension tolerances are critical to achieve a perfect fit for your project.

Applications And Recommended Thicknesses

Choosing the right acrylic sheet thickness depends largely on the specific application and the performance requirements of your project.

Picture Frames

For lightweight and flexible needs, acrylic sheets between 1mm and 3mm thickness are ideal.

These thin sheets offer excellent ease of cutting, shaping, and bending, making them perfect for craft projects, indoor signage, decorative panels, and applications requiring flexibility without compromising durability.

Additionally, their lightweight nature makes handling and installation easier while maintaining sufficient strength for everyday use.

Display Cases

Display cases require acrylic sheets that combine clarity with durability to protect and showcase valuable items effectively.

Medium thickness acrylic sheets, typically between 4mm and 10mm, are ideal for this purpose as they provide a sturdy, impact-resistant barrier that maintains excellent transparency.

These sheets resist scratches and are easy to clean, ensuring that displays remain visually appealing over time.

Furniture

Thick acrylic sheets of 12mm and above deliver maximum strength, rigidity, and durability.

These robust sheets are perfect for demanding applications such as tabletops, countertops, structural furniture components, and architectural installations that require long-lasting support and resistance to wear.

Engraving Projects

Thinner sheets (up to 6mm) are generally easier to cut and engrave with precision using standard tools and laser cutters, making them ideal for detailed and intricate designs.

In contrast, thicker sheets often require specialized equipment and multiple passes to achieve clean, professional results.

Practical Tips For Choosing Acrylic Sheet Thickness

Selecting the right acrylic sheet thickness can make a significant difference in the success of your project. Start by clearly defining the purpose and environment where the acrylic will be used.

For load-bearing applications like furniture or shelving, opt for thicker sheets to ensure durability and support.

If flexibility and ease of shaping are priorities, choose thinner sheets that can bend without cracking. Always consider impact resistance, especially for protective barriers or outdoor use, where thicker, cast acrylic sheets provide enhanced strength.

Additionally, factor in the ease of cutting and finishing—thinner sheets are generally easier to work with, while thicker sheets may require specialized tools.

Don’t forget to account for precise measurements and tolerances when ordering cut-to-size sheets to guarantee a perfect fit.

Consulting with a knowledgeable team or supplier can also help you add the right features such as radius corners or polished edges, ensuring your acrylic sheet not only meets functional needs but also looks professional and polished.

By balancing these considerations, you can confidently choose the perfect acrylic sheet thickness tailored to your specific project requirements.

Conclusion

Choosing the right acrylic sheet thickness is a crucial step to ensure the success and durability of your project.

By carefully considering factors such as load-bearing requirements, impact resistance, flexibility, and the specific application, you can select the perfect thickness that balances strength and aesthetics.

Many customers find it helpful to watch a detailed video explaining these factors before making a purchase, so be sure to check if your supplier offers such resources.

Sometimes, orders may be temporarily blocked due to stock issues or customization requests, but you can usually drop a message to the shop’s support team via their menu options to continue your order smoothly.

Additionally, utilizing cut-to-size services with precise tolerances and added customization options like radius corners and polished edges can enhance both the functionality and appearance of your acrylic sheets.

For the best results, consult with an experienced team to guide you through the selection process, ensuring your project is supported by durable, high-quality acrylic sheets tailored to your needs.