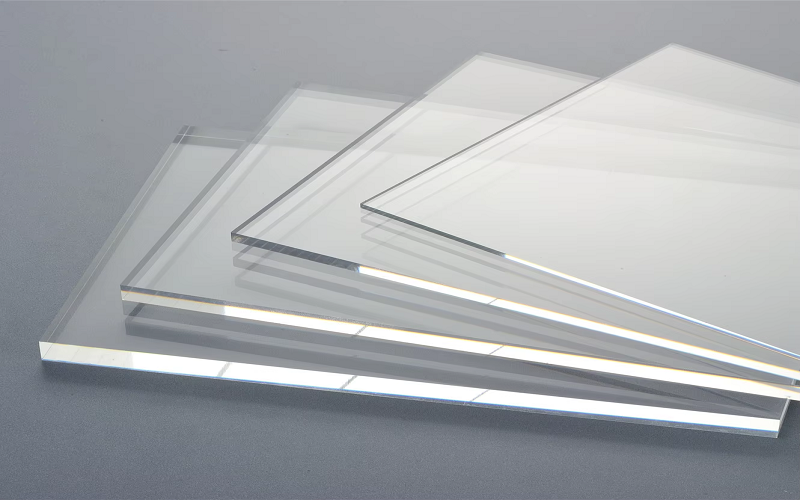

An acrylic sheet is a versatile, durable plastic material known for its clarity and strength. Also commonly referred to as acrylic glass, this material is a lightweight, shatter-resistant alternative to traditional glass, making it popular in many industries.

It’s an excellent alternative to glass, providing high transparency and impact resistance for a wide range of applications.

This article explores the types, characteristics, advantages, and uses of acrylic sheets, helping you understand why they might be the perfect choice for your needs.

What Is Acrylic Sheet?

Acrylic , chemically known as polymethyl methacrylate (PMMA), are a type of plastic renowned for their exceptional clarity and versatility.

This material offers a glass-like transparency and is often referred to as “organic glass” or known as plexiglass sheets. Acrylic materials are commonly found in various industries in forms such as pellets, sheets, or tubes.

Acrylic sheets are primarily composed of methyl methacrylate (MMA), produced through a polymerization reaction, and possess glass-like high transparency. Therefore, they are often referred to as “organic glass” or “Plexiglass.”

Unlike traditional glass, clear acrylic sheets are much lighter and significantly more impact-resistant, making them a preferred choice in many applications.In the market, all sheets made from transparent plastics (such as PS, PC) or low-quality recycled MMA are generally called organic glass.

To distinguish quality, high-purity MMA raw materials are used to produce premium PMMA sheets, specifically named “acrylic sheets,” differentiating them from ordinary organic glass sheets.

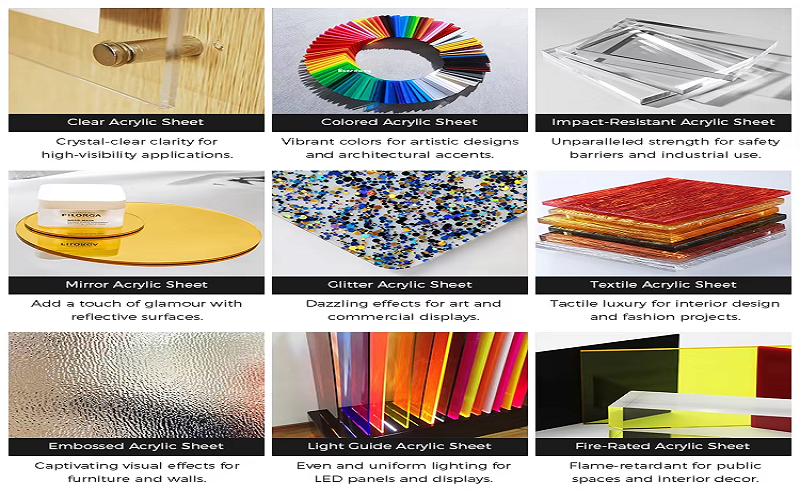

Types Of Acrylic Sheets

Acrylic sheets are generally manufactured using the following two processes: casting and extrusion.

Cast Acrylic Sheets

This type of acrylic sheets are created through a process that involves pouring liquid acrylic into molds where it is allowed to set and harden.

This method results in sheets with high molecular weight, providing superior rigidity, strength, and excellent chemical resistance.

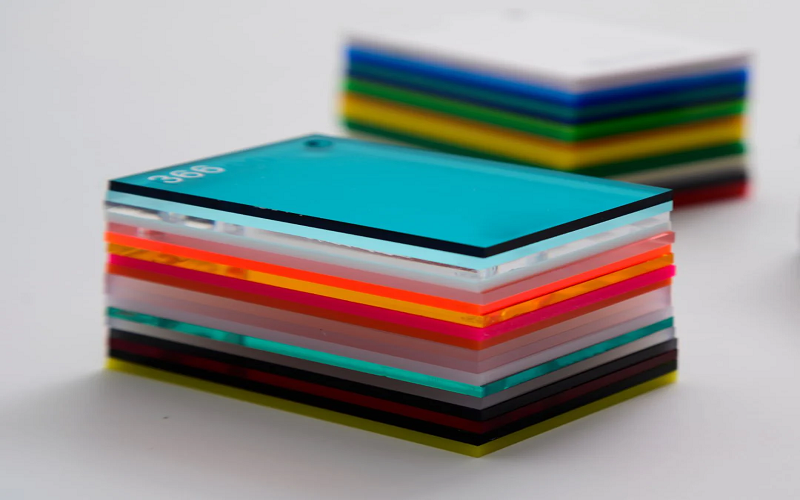

One of the standout features of cell casting cast acrylic sheets is their versatility in terms of color and surface texture. They can be produced in small batches, allowing for a wide range of customization options, making them ideal for specialized applications.

While cast acrylic sheets are known for their higher quality and durability, they are also more expensive than their extruded counterparts. Their superior properties make them perfect for products that require high optical clarity and strength, such as display cases, signage, and clear acrylic sheets aquariums.

Additionally, they are often used in applications that demand precise machining and intricate processes, as they can be easily laser cut, custom cut, and finished with polished edges.

Extruded Acrylic Sheets

Extruded acrylic sheets are produced by heating acrylic pellets until they melt and then forcing the molten material through a die to form continuous sheets.

In this process, the raw acrylic resin is melted and pushed through a die, resulting in continuous sheets of uniform thickness.This process results in sheets with lower molecular weight compared to cast acrylic, making them less rigid but easier to bend and shape.

Extruded acrylic sheets are particularly advantageous for applications requiring large sheets and rapid production, as they can be quickly vacuum-formed and thermoformed.

One of the primary benefits of extruded acrylic sheets is their uniform thickness, which makes them ideal for applications where uniformity is crucial.

They are also generally more cost-effective than cast acrylic sheets, making them a popular choice for large-scale projects and budget-conscious applications.

Despite their lower mechanical strength, extruded acrylic sheets are still significantly stronger than traditional glass, offering a durable and lightweight alternative to glass for various uses.

Characteristics Of Acrylic Sheet

Acrylic sheets are prized for their unique characteristics, which make them suitable for a wide range of applications.

Higher Transparency Than Ordinary Glass

One of the most notable features is their high transparency, with a light transmittance of over 92%, surpassing that of regular glass. This optical clarity makes acrylic sheets ideal for applications requiring a clear view and vibrant displays.

Weather Resistance

Acrylic sheets can withstand prolonged exposure to sunlight without yellowing or becoming brittle, making them perfect for outdoor use.

Machinability

Acrylic sheetscan be cut, drilled, engraved, thermoformed, glued, and polished to create intricate shapes and designs.

The durability and strength of acrylic sheets make them especially suitable for industrial environments and heavy-duty applications.

Lightweight And Strong

Their lightweight yet strong nature, being half the weight of glass yet 10-20 times more impact-resistant and shatter resistant, adds to their appeal for both safety and portability.

With a variety of colors, thicknesses, and surface finishes available, acrylic sheets offer endless possibilities for customization.

Advantages Of Acrylic Sheet

Acrylic sheets boast several advantages:

- Excellent weather resistance, making them ideal for outdoor applications

- Resistance to UV light, preventing yellowing or degradation over time, while also providing uv protection

- Long-lasting clarity and performance

- Environmentally friendly and recyclable, aligning with the trend towards sustainable materials

Disadvantages Of Acrylic Panels

Disadvantages of acrylic panels include:

- Surface Easily Scratched: Acrylic has a lower surface hardness than glass,, making it prone to scratches during daily use, which can affect its appearance and transparency.

- Relatively Higher Cost: Compared to common plastics such as PVC, acrylic production costs are higher, especially for cast acrylic sheets which are more expensive.

- Limited Heat Resistance: Acrylic may soften and deform at high temperatures (around 100°C or above), making it unsuitable for high-temperature environments.

What Is Acrylic Sheet Used For?

Acrylic sheets are incredibly versatile and find applications across various industries due to their unique properties.

Their high transparency, ease of processing, weather resistance, and range of options make them suitable for everything from construction and advertising to medical equipment and home decor.

Construction Industry

In the construction industry, acrylic sheets are widely used for windows, skylights, soundproofing walls, and glass facades. Their impact resistance and aesthetic appeal make them a common alternative to traditional glass, providing better durability and safety.

Moreover, acrylic sheets offer excellent thermal insulation and soundproofing, enhancing the functionality of modern buildings.

Architects and builders appreciate acrylic sheets for their lightweight nature and ease of installation. Whether it’s for residential or commercial projects, these sheets contribute to both the structural integrity and visual appeal of the construction, making them an essential material in the industry.

Advertising Industry

The advertising industry has embraced acrylic sheets for creating eye-catching signs, displays, and lightboxes. Their high transparency and vibrant color options make them ideal for showcasing promotional content.

Acrylic sheets can be easily shaped and customized, allowing for creative and dynamic advertising solutions that capture attention and convey messages effectively.

Medical Industry

In the medical field, acrylic sheets are valued for their non-toxic properties and clarity. They are used in the manufacturing of incubators, medical devices, and protective barriers.

The material’s transparency allows for easy observation and monitoring, while its durability ensures safety and longevity in demanding medical environments.

Furniture

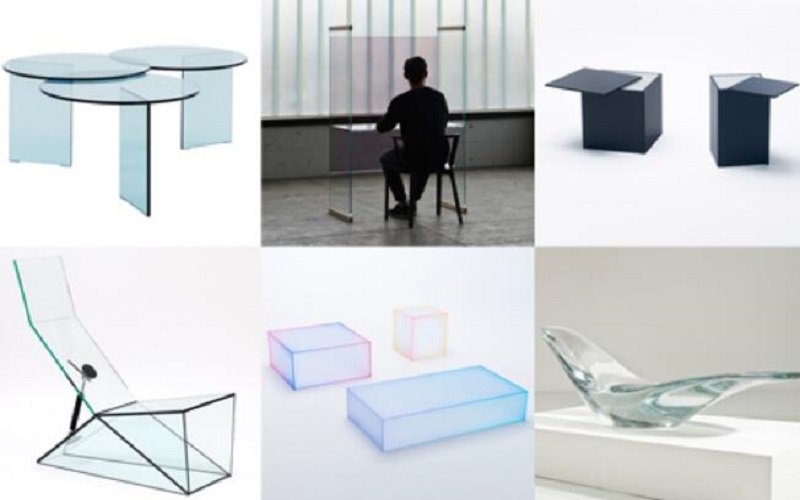

Acrylic sheets are popular in furniture design for their modern look, durability, and lightweight nature. They are used for items like panels, picture frames, lampshades, storage boxes, bathroom fixtures, and wall shelves.

Ideal for DIY projects, acrylic sheets offer versatility and ease of use, enabling custom, stylish home improvements such as bookshelves and coffee tables.

DIY Projects

Whether you’re working on decorative panels, modern sculptures, or custom jewelry, clear acrylic sheets offer a transparent, glass-like finish that enhances any creative project.

Their ability to be easily cut, shaped, and molded means you can bring even the most intricate designs to life, making them ideal for a wide range of DIY projects.

With a broad range of thicknesses and sizes available, acrylic sheets are suitable for everything from small crafts to large-scale art installations, ensuring your projects are both beautiful and long-lasting.

Working With Acrylic Sheets: Cutting and Shaping

Working with acrylic sheets is both accessible and rewarding, provided you use the right tools and techniques. For simple, straight cuts, scoring and snapping is a cost-effective method that works well for thinner sheets.

For more complex shapes or thicker materials, sawing with a fine-toothed blade designed for plastics ensures clean, precise edges. If you have access to a laser cutter, you can achieve intricate designs and polished edges with minimal effort, making laser cutting a popular choice for custom and professional projects.

Shaping acrylic sheets is also straightforward—by applying gentle heat with a heat gun or using a vacuum former, you can bend and mold the material into curves or three-dimensional forms.

This versatility makes acrylic sheets suitable for a wide range of applications, from signage and displays to custom furniture and art pieces. With a little practice and the right approach, you can unlock the full potential of acrylic sheets for your next project.

Environmental Considerations Of Acrylic Sheets

While acrylic sheets are made from synthetic polymers derived from petroleum, they also offer several environmental benefits.

Many acrylic sheets are recyclable, and some manufacturers now produce eco-friendly options using recycled materials or bioplastics, helping to reduce waste and the overall environmental footprint. Additionally, the durability and longevity of acrylic sheets mean they often outlast other materials, reducing the need for frequent replacement.

Acrylic sheets can also contribute to sustainability in various applications, such as energy-efficient windows, solar panels, and insulation products that help lower energy consumption.

By choosing recycled or responsibly manufactured acrylic sheets and using them thoughtfully, you can enjoy the benefits of this versatile material while supporting a more sustainable future.

How To Choose Acrylic Sheet?

Selecting the right acrylic sheet involves careful consideration of several factors. Start by examining the surface characteristics of the sheet; high-quality acrylic should have a smooth, clear surface without any yellowing or discoloration. The clarity and transparency of the sheet are crucial indicators of its quality.

Another practical tip is to check the burn performance of the acrylic sheet. High-quality acrylic should not burn easily, and if it does, it should not emit a strong, unpleasant odor.

Lastly, pay attention to the thickness specifications. The thickness of the acrylic sheet directly affects its strength and stability, so ensure that the sheet meets the required standards for your specific application.

Summary

Acrylic sheets offer a perfect blend of aesthetics and functionality, making them a versatile material for numerous applications.

Their high transparency, durability, and ease of processing make them ideal for use in different applications ,such as construction, advertising, medical fields, and home decor.

Despite some drawbacks like susceptibility to scratching and higher cost, the benefits of acrylic sheets far outweigh the disadvantages.

As we continue to seek innovative and sustainable materials, acrylic sheets stand out as a practical and stylish choice. Embrace the versatility of acrylic in your next project and discover how this remarkable material can transform your space.

MUDUSA offers premium acrylic sheets customized to diverse needs of customer, whether as a sleek glass substitute for windows and doors or for creating stylish shelves and furniture.

Available in various sizes and thicknesses, our high-quality plastic sheets cater to diverse customer requirements. Be sure to measure precisely before ordering to ensure the perfect fit for your project!