Acetal plastic sheets are a popular choice in the world of engineering plastics due to their exceptional strength, stiffness, and excellent dimensional stability.

Acetal plastic sheets are a type of high-performance engineering plastic, valued for their versatility and reliability in demanding environments.

This guide will provide you with a clear and straightforward overview of acetal plastic sheets, including their key features, and common uses across industries like food processing and automotive manufacturing.

What Are Acetal Plastic Sheets?

Acetal plastic sheets, also known as polyoxymethylene (POM), are high-performance engineering plastics prized for their exceptional mechanical properties.

They are easily cut and machined into precision parts such as gears, bearings, and bushings used in industries ranging from automotive to food processing.

Acetal plastic is also available in rods, which can be machined for similar applications. Both acetal sheets and rods are known for their ease of machining into complex shapes.

Additionally, acetal plastic sheets offer good electrical properties and resistance to solvents, further enhancing their versatility for various industrial projects and other applications.

Types Of Acetal Sheets

Acetal plastic sheets are primarily available in two types, each with unique properties that suit different mechanical applications.

Homopolymer Acetal (Delrin®) Sheet

Known for its high strength, stiffness, and toughness, homopolymer acetal offers superior physical properties and excellent dimensional stability.

It is ideal for applications requiring high tensile strength and precision parts with tight tolerances.

Copolymer Acetal (POM-C) Sheet

This type provides enhanced chemical resistance and better performance in environments involving moisture, heat, and solvents.

Copolymer acetal also reduces the risk of centerline porosity, making it suitable for parts exposed to continuous high heat or water.

Properties Of Acetal Plastic Sheets

Acetal plastic sheets possess a range of properties that make them highly desirable for various industrial and mechanical applications.

Physical Properties

Acetal plastic sheets exhibit outstanding physical properties that make them a top choice for engineering applications.

They have high tensile strength and excellent stiffness, providing durability and reliability in demanding environments.

Acetal plastic sheets are also tough, allowing them to withstand significant mechanical stress without cracking or deforming.

Additionally, acetal sheets possess a low coefficient of friction and superior wear resistance, which help reduce friction and abrasion in moving parts, extending the lifespan of components.

Chemical Resistance

Acetal plastic sheets are highly valued for their excellent chemical resistance, which allows them to withstand exposure to a wide range of solvents, fuels, and industrial chemicals without degrading.

This resistance makes acetal sheets ideal for use in environments where contact with harsh chemicals is common, such as in automotive, food processing, and chemical manufacturing industries.

The material’s ability to resist swelling, cracking, or softening when exposed to chemicals ensures long-lasting performance and reliability in demanding mechanical applications.

Moisture Resistance

One of the standout features of acetal plastic sheets is their exceptional moisture resistance.

These sheets absorb very little moisture, which helps maintain their mechanical strength, dimensional stability, and physical properties even in highly humid or wet environments.

This low moisture absorption prevents swelling, warping, and degradation, making acetal ideal for applications in food processing, automotive, and other industrial settings where exposure to moisture is frequent.

Ease Of Machining

Acetal plastic sheets are renowned for their excellent machinability, making them a preferred choice for manufacturing precision parts.

Their uniform consistency and stability allow them to be easily cut, drilled, milled, and shaped without chipping or cracking.

This ease of machining reduces production time and costs, enabling efficient fabrication of complex components such as gears, bushings, and bearings.

Common Applications Of Acetal Plastic Sheets

Acetal plastic sheets are widely used across various industries due to their excellent mechanical and chemical properties.

They are also commonly used to manufacture fittings and are suitable for other projects requiring strength and durability.

Bushings And Rollers

Acetal plastic sheets are an excellent material choice for manufacturing bushings and rollers due to their high strength, low coefficient of friction, and outstanding wear resistance.

The excellent dimensional stability of acetal sheets maintains tight tolerances, which is crucial for precision parts like bushings and rollers that require consistent performance.

Automotive Components

Acetal plastic sheets make an excellent choice for automotive components due to their high tensile strength, excellent dimensional stability, and outstanding chemical resistance.

Additionally, acetal’s low coefficient of friction and wear resistance contribute to the durability and efficiency of moving parts, making it ideal for precision components that require tight tolerances and long service life in the automotive industry.

Food Processing Equipment

Acetal plastic sheets are widely used in food processing equipment due to their excellent moisture resistance, chemical resistance, and compliance with FDA regulations.

They are commonly utilized for conveyor parts, food contact surfaces, seals, and gaskets, where low friction and wear resistance are critical for smooth operation and long service life.

Industrial Machinery

Acetal plastic sheets are extensively used in industrial machinery for their exceptional mechanical properties and durability.

Their low coefficient of friction and excellent wear resistance make them ideal for components such as pump and valve parts, wear pads, and conveyor system elements.

These sheets maintain excellent dimensional stability under continuous mechanical stress and varying environmental conditions, ensuring reliable performance in demanding industrial applications.

Choosing The Right Acetal Plastic Sheet For Your Project

When you select the appropriate acetal plastic sheet, you ensure optimal performance and longevity of your mechanical or industrial application.

Factors to consider include the type of acetal—whether homopolymer acetal or acetal copolymer—based on the specific requirements of strength, chemical resistance, and environmental exposure.

For projects demanding high tensile strength and excellent dimensional stability, homopolymer acetal sheets, such as Delrin®, are ideal.

Conversely, if your application involves exposure to moisture, heat, or harsh chemicals, acetal copolymer sheets offer superior chemical resistance and reduced risk of centerline porosity.

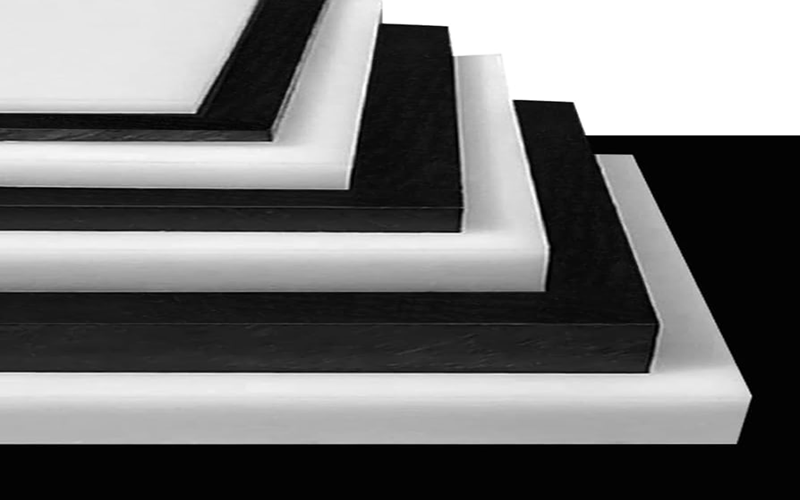

Additionally, consider the sheet’s thickness, color (natural or black), and machinability to match your precision parts needs.

Compared to metals, acetal plastic sheets offer significant advantages, including high strength, durability, resistance to wear and environmental factors, and greater ease of fabrication.

By carefully evaluating these factors, you can choose an acetal plastic sheet that not only meets your project’s technical specifications but also enhances durability, wear resistance, and ease of fabrication for successful outcomes in various industrial applications.

Conclusion

Acetal plastic sheets are a versatile and reliable choice for a wide range of industrial and mechanical applications.

Their combination of high tensile strength, excellent dimensional stability, low coefficient of friction, and outstanding wear resistance makes them ideal for precision parts that require tight tolerances and long-lasting performance.

Whether you choose homopolymer acetal for superior strength or acetal copolymer for enhanced chemical and moisture resistance, these materials offer exceptional machinability and durability.

By selecting the right type of acetal plastic sheet, you can ensure your project benefits from superior abrasion resistance, chemical resistance, and consistent physical properties, ultimately leading to improved efficiency and longevity in demanding environments.

To learn more about acetal plastic sheets and how they can benefit your specific applications, explore our resources or contact us for expert guidance.