Blue transparent plastic sheets are versatile materials widely used in various applications, from creative projects to industrial fabrication.

Known for their vibrant color and clarity, these sheets allow light to pass through while providing durability and impact resistance.

Whether you need them for eye catching signage, displays, or custom crafts, understanding their features and uses will help you make the best choice for your project.

This article will comprehensively analyze the characteristics, production process, application cases and purchasing guide of transparent blue plastic sheets to help you easily master the infinite possibilities of this versatile product!

Main Types Of Blue Transparent Plastic Sheets

Blue transparent plastic sheets are commonly made from three primary materials: polycarbonate acrylic, and PET . Each material offers unique properties suited for different applications, ensuring high transparency (>85% light transmission) with a stunning blue tint.

Blue Transparent Polycarbonate Sheet

This ultra-durable PC sheet boasts exceptional impact resistance (250x stronger than glass) and temperature tolerance (-40°C to 120°C).

With 88% light transmission, it’s perfect for industrial safety shields, automotive headlamp covers, and outdoor roofing—ideal where strength and weather resistance are key.

Blue Transparent Acrylic Sheet

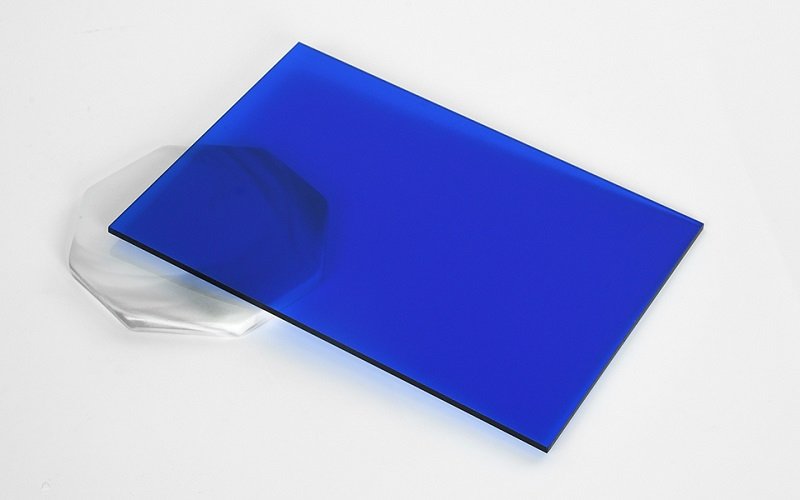

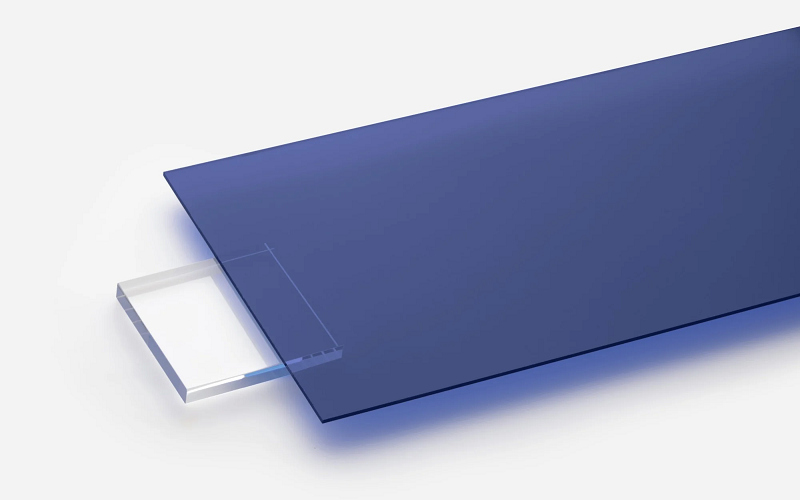

This transparent colored acrylic sheet features a light blue tint that allows light to pass through clearly without diffusion.

Blue transparent acrylic sheets enable objects on the other side to be seen distinctly, much like tinted windows, making them ideal for a wide range of creative projects.

Boasting 92% light transmission and crystal-clear clarity, it’s the top choice for LED signboards, interior partitions, display cases, and art installations—offering unmatched aesthetics and easy cutting/forming.

Blue Transparent PET Sheet

Flexible and cost-effective, PET sheets provide excellent chemical resistance and recyclability, with up to 90% light transmission. Best for packaging films, greenhouse covers, and thin protective wraps—where lightweight flexibility and eco-friendliness matter most.

These sheets are available in various thicknesses and sizes, including custom size options, to suit different project requirements.

Whether you need a thin 1/8 inch sheet for lightweight signage or a thicker 1/4 inch panel for structural applications, transparent blue acrylic sheets offer flexibility and performance for a wide range of uses.

How To Manufacture Transparent Blue Plastic Sheet ?

The manufacturing process of transparent blue plastic sheets typically involves several key steps: raw material selection, coloring, forming, and post-processing.

First, manufacturers select high-quality plastic resin. Then, by adding specific blue dyes or pigments, they achieve uniform coloring of the plastic sheets, ensuring vibrant color and high transparency.

In the forming stage, common methods include extrusion and casting. Extrusion is suitable for mass production, where molten plastic is pushed through molds to form sheets with uniform thickness.

Casting involves pouring liquid plastic into molds to cure, resulting in higher optical quality and better scratch resistance, often used for high-end transparent blue cast acrylic sheets known .

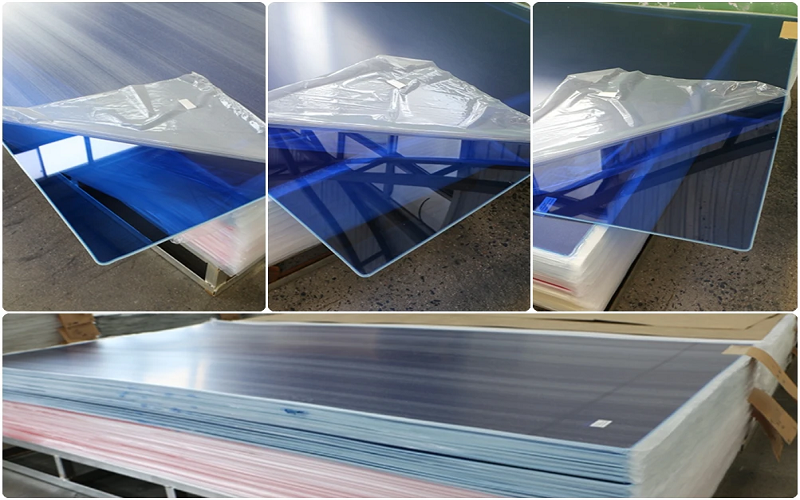

Finally, the produced plastic sheets undergo post-processing such as cutting, polishing, and drilling to meet different customer size and usage requirements.

Some plastic sheet manufacturers also offer custom cutting and polished finishing and drilling services, allowing users to purchase finished sheets tailored for their projects.

Throughout the manufacturing process, strict control of thickness, tolerance, and optical performance ensures that transparent blue plastic sheets are both aesthetically pleasing and practical, widely used in advertising signage, display cases, architectural decoration, and other fields.

Blue Transparent Plastic Sheet Cut To Size

When it comes to working with blue transparent plastic sheets, having the option to cut to size is essential for ensuring your project fits perfectly and meets your specific requirements.

Many suppliers offer custom cut-to-size services, allowing you to specify the exact width, length, and thickness you need, whether for signage, displays, or creative crafts.

Custom cut sheets help maintain precision and reduce waste, making them ideal for professional fabrication processes such as laser cutting, CNC routing, and engraving.

These services often come with options like drill holes, edge polishing, or sanding to enhance the finish and functionality of the final product.

When ordering, it’s important to consider the quantity and dimensions carefully to get the best cart price and ensure timely shipping. Most suppliers provide stock options in popular sizes such as 12″ x 24″, 24″ x 48″, and custom dimensions to suit your project needs.

By choosing blue transparent plastic sheets cut to size, you can streamline your fabrication process, achieve eye-catching signage and displays, and maintain the high impact resistance and clarity that make these acrylic sheets a top choice for many applications.

Applications of Blue Transparent Plastic Sheets

Blue transparent plastic sheets are widely used in various fields due to their excellent optical performance and durability. Here are some typical application scenarios:

- Advertising Signs and Display Racks

Blue transparent plastic sheets allow light to pass through and have vibrant colors, making them ideal for creating eye-catching advertising signs and display racks. Their good weather resistance ensures long-term color and structural stability when used outdoors, making them a highly recommended material choice. - Architectural Decoration

In architectural design, blue transparent plastic sheets are often used for partitions, skylights, and curtain walls as decorative elements. They not only provide natural lighting but also create a strong modern visual effect. - Industrial Protective Covers

Due to their high impact strength and temperature resistance, blue transparent plastic sheets are commonly used as protective covers for machinery and equipment, ensuring safety while allowing easy observation of operational status. - Lighting Fixtures and Furniture Design

Taking advantage of their excellent light transmission and ease of processing, designers often use blue transparent plastic sheets to make lamp covers and furniture decorative parts, adding a sense of fashion and technology. - Crafts and Educational Models

Blue transparent plastic sheets are suitable for laser cutting and engraving, widely applied in craft production and educational model development, helping to enhance the detail and visual appeal of the works.

In summary, with their unique color and outstanding performance, blue transparent plastic sheets have become an indispensable material choice in many industries.

Conclusion

Blue transparent plastic sheets, as multifunctional and high-value materials, are widely used across diverse fields ranging from creative projects to industrial manufacturing.

Their vibrant color, high light transmission, impact resistance, and easy processability make them the ideal choice for custom signage, display racks, protective covers, and decorative elements.

Whether you choose transparent acrylic, polycarbonate, or PET materials, these sheets offer excellent light transmission and durability, precisely meeting your needs.

For more information, product options, or to request a custom quote, please contact MUDUSA Acrylic via email. Let blue transparent plastic sheets unlock infinite possibilities for your creative and industrial projects!