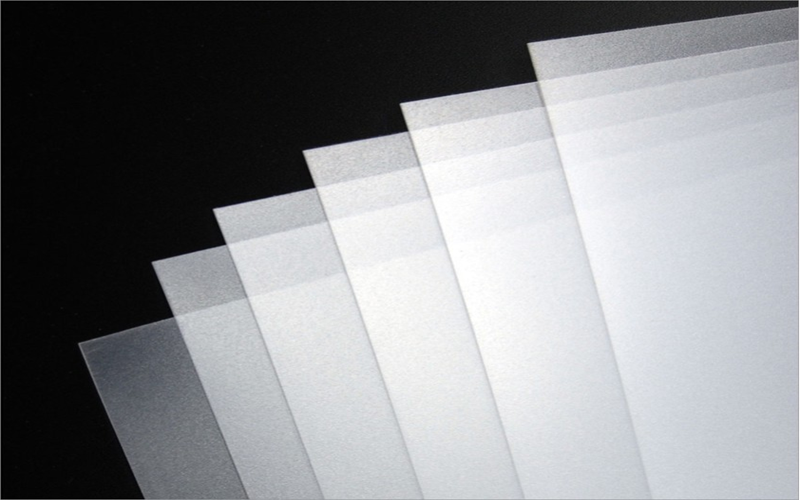

Polypropylene sheets are a versatile and widely used type of plastic sheets known for their durability, chemical resistance, and lightweight properties.

Commonly used in various industries, these sheets offer excellent impact resistance and are suitable for applications ranging from packaging and containers to industrial and chemical processing.

This article provides a comprehensive overview of polypropylene sheets, their benefits, and their common uses.

What Is Polypropylene Plastic Sheet?

Polypropylene plastic sheet is a type of thermoplastic sheet made from polypropylene plastic or polypropylene copolymer (PP-C). It is widely used due to its excellent chemical resistance, impact resistance, and lightweight properties.

Polypropylene sheets exhibit outstanding chemical resistance, capable of withstanding various organic solvents, making them suitable for many demanding industrial environments.

Additionally, pp sheets possess high tensile strength and are rigid, performing excellently in the manufacturing of products such as trays, containers, tubes, and rods. They have properties similar to ABS, offering a balance of durability and flexibility.

These sheets also offer resistance to low temperatures and are environmentally friendly and non-toxic, meeting food contact standards. They are widely applied in food packaging, medical devices, electrical insulation, and chemical processing.

With a variety of sizes and thicknesses available to meet different customer needs, polypropylene sheets are easy to weld and form, greatly enhancing manufacturing efficiency and product versatility.

As an economical and high-performance plastic material, polypropylene plastic sheets hold an important position in manufacturing and industrial applications worldwide.

Many plastic sheet manufacturers are committed to providing high-quality polypropylene sheet solutions to meet the requirements of various projects and demanding applications.

Advantages Of Using PP sheets

Using PP plastic sheets (polypropylene sheets) offers the following main benefits, summarized concisely with practical application scenarios:

Lightweight and Durable

PP sheets are lightweight, easy to handle and process, while also possessing high impact resistance and wear resistance, resulting in a long service life. They are suitable for packaging, construction, and other applications.

Excellent Chemical Stability

They resist acids, alkalis, and various chemical substances, making them ideal for chemical laboratories, tank linings, and medical device manufacturing.

Environmentally Friendly and Recyclable

PP sheets are 100% recyclable and made from recycled materials, meeting sustainability requirements and reducing environmental impact, making them suitable for green projects.

Additionally, manufacturers continuously generate innovative solutions to enhance the performance and versatility of polypropylene sheets, ensuring they meet the evolving demands of various industries.

Easy to Process and Customize

They can be processed through cutting, thermoforming, welding, and other methods to meet diverse needs in DIY, industrial design, or custom packaging.

Cost-Effective

With low production costs and affordable prices, they are suitable for large-scale applications such as temporary construction panels or disposable medical packaging.

Good Insulation Performance

Excellent electrical insulation and heat resistance make them suitable for electronic product housings or automotive parts (such as battery boxes).

Note: Although PP sheets have significant advantages, their performance may degrade at high temperatures (>100°C) or with prolonged exposure to ultraviolet light. Stabilizers should be added or appropriate thickness chosen to cope with specific environments. Manufacturers with expertise in polypropylene sheets can provide tailored solutions to ensure optimal performance in various demanding applications.

Applications Of Polypropylene Sheets

Polypropylene sheets are widely used across various industries due to their versatile properties. In packaging, they serve as durable and lightweight materials for containers, trays, and food packaging, offering excellent chemical resistance and safety for food contact.

In the chemical processing industry, these sheets are ideal for tank linings, chemical storage, and handling equipment because of their resistance to acids, alkalis, and organic solvents.

The electrical industry benefits from polypropylene sheets’ superior insulation properties, utilizing them in housings, electrical components, and insulating barriers.

In the automotive sector, their lightweight and impact resistance make them suitable for battery boxes, interior panels, and protective covers.

Additionally, polypropylene sheets are commonly used in the manufacturing of signage and displays, often replacing cardboard due to their durability, weather resistance, and excellent sign-making capabilities.

Their ability to be easily cut, welded, and thermoformed allows for customized solutions in industrial design and construction projects.

Furthermore, the semiconductor industry relies on polypropylene sheets for components requiring high purity and chemical stability. The versatility of polypropylene sheets also extends to medical device manufacturing and consumer products, highlighting their crucial role in multiple demanding applications.

Manufacturers and suppliers continuously work to improve the quality and variety of polypropylene sheets, offering a broad range of sizes, thicknesses, and grades to meet the specific request of businesses and customers worldwide.

Conclusion

In summary, polypropylene sheets are a versatile and durable plastic material widely used across numerous industries due to their excellent chemical resistance, lightweight nature, and ease of processing.

Companies specializing in polypropylene sheet manufacturing are committed to providing high-quality products and tailored solutions to meet the diverse needs of their customers.

For those seeking more detailed information or specific product options, it is advisable to contact reputable manufacturers or suppliers who can offer expert guidance and support.

Polypropylene sheets continue to be an essential material for various demanding applications, combining performance, cost-effectiveness, and environmental benefits.