Scratch-resistant acrylic sheets have become a popular material across various industries due to their remarkable durability, versatility, and aesthetic appeal.

As a lightweight, shatter-resistant alternative to glass, these acrylic sheets are engineered with a specialized coating that enhances their resistance to scratches, abrasions, and everyday wear.

This article explores the properties, applications, benefits, and considerations of using scratch-resistant acrylic sheets in modern design and manufacturing.

Is Acrylic Sheet Scratch Resistant?

Acrylic sheets are known for their excellent clarity and lightweight properties, making them a popular choice for many applications.

However, when it comes to scratch resistance, standard acrylic sheets are more prone to surface scratches compared to glass or specialized coatings.

To address this, scratch resistant acrylic sheet is engineered with a durable protective coating that significantly enhances their abrasion resistance.

This coating helps protect the surface from everyday wear, dirt, dust, and minor impacts, maintaining the sheet’s clarity and smoothness over long-term use.

PLEXIGLAS®’s exceptional scratch resistance sets it apart from other plastics, making it an ideal choice for applications such as furniture, exhibition booth construction, shopfitting, and photo glazing, where durability and aesthetic appeal are paramount.

Key Properties Of Scratch Resistant Acrylic Sheet

Scratch resistant acrylic sheets boast a combination of features that make them an excellent choice for various demanding applications. Key properties include:

Enhanced Scratch Resistance

Thanks to the specialized hard coating, these sheets resist scratches and abrasions far better than standard acrylic, preserving clarity and appearance over time.

High Impact Strength

While maintaining the lightweight nature of acrylic, these sheets offer superior impact resistance compared to traditional glass, making them safer, more impact resistant, and more durable in use.

Optical Clarity

Scratch resistant acrylic sheets provide excellent transparency, comparable to glass, ensuring clear visibility for displays, windows, and signage.

Chemical Resistance

The coating also improves resistance to chemicals and cleaning agents, allowing for easier maintenance without damaging the surface.

Lightweight and Easy to Fabricate

These sheets are significantly lighter than glass and can be easily cut, drilled, and shaped to fit specific project requirements.

UV Resistance

Many scratch resistant acrylic sheets are formulated to resist degradation from UV exposure, making them suitable for outdoor use without yellowing or becoming brittle.

Available in Various Sizes and Thicknesses

This versatility allows them to be used in a wide range of applications, from small display cases to large window panes.

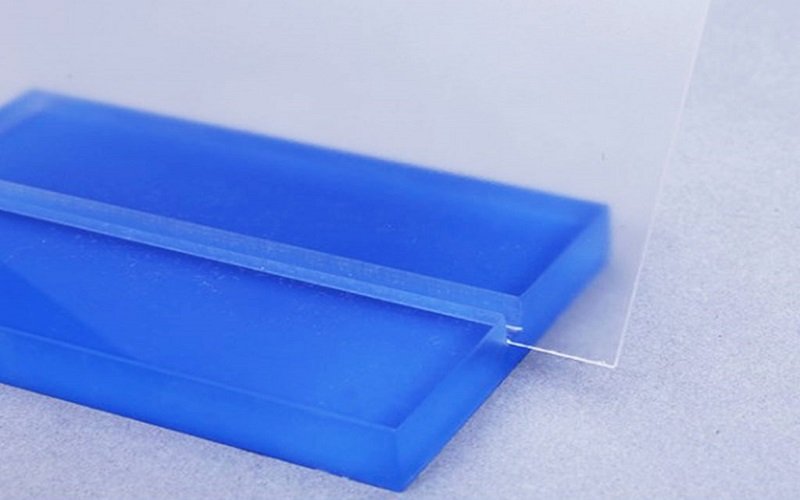

Protective Film

Often, a protective film covers the sheet during packing to prevent damage during shipping and handling, ensuring the quality upon delivery.

These properties combine to make scratch resistant acrylic sheets an ideal material for projects requiring durability, clarity, and long-term performance.

How To Make Plexiglass Scratch Resistant?

Making plexiglass scratch resistant involves applying a specialized hard coating to the surface of the acrylic sheet.

This coating is designed to increase the abrasion resistance and protect the sheet from scratches caused by everyday handling, cleaning, and environmental factors.

There are two common methods used to enhance the scratch resistance of plexiglass:

- Coating Application: A durable protective film or hard coating is applied either on one side (single side) or both sides (double side) of the acrylic sheet. This coating significantly improves the surface hardness, making it more resistant to scratches, chemicals, and wear without compromising the clarity and lightweight nature of the material.

- Material Engineering: Some manufacturers produce abrasion resistant acrylic sheets by incorporating additives or altering the acrylic formulation to improve impact strength and surface durability. These durable acrylic sheets maintain the optical clarity of traditional glass while offering superior resistance to scratches and impacts.

These abrasion resistant acrylic sheets are particularly suitable for high-traffic or commercial environments where maintaining a smooth, scratch-free surface is essential for both aesthetics and functionality.

Proper handling and cleaning also play a vital role in preserving the scratch resistance of plexiglass. Using soft cloths, mild cleaners, and avoiding abrasive materials will help maintain the protective coating and extend the lifespan of the acrylic sheet.

Applications Of Scratch-Resistant Acrylic Sheet

The durability and versatility of scratch-resistant acrylic sheets make them suitable for a wide range of applications, including:

- Architectural Design: Used in windows, skylights, and partitions, these sheets provide a durable, transparent alternative to glass in residential and commercial buildings.

- Retail and Display: Scratch-resistant acrylic is a go-to material for display cases, signage, and point-of-purchase displays due to its clarity and resistance to wear.

- Automotive Industry: Acrylic sheets are used for vehicle windows, headlight covers, and interior panels, where durability and lightweight properties are critical.

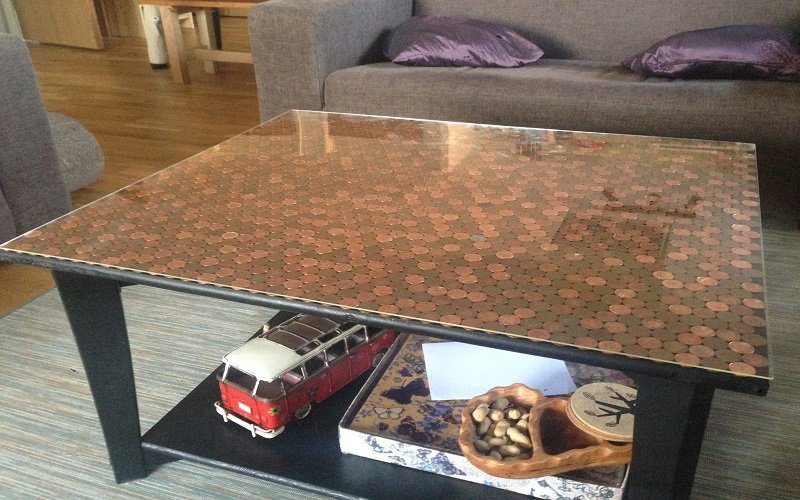

- Furniture and Decor: Designers use these sheets for tabletops, shelving, and decorative panels, combining aesthetics with practicality.

- Medical and Laboratory Equipment: The material’s resistance to chemicals and scratches makes it ideal for protective barriers and equipment housings in healthcare settings.

- Electronics: Scratch-resistant acrylic is used in screens, touch panels, and protective covers for devices, ensuring longevity and clarity.

Benefits Of Using Scratch Proof Acrylic Sheets

With a specialized coating that enhances their resistance to scratches and abrasions, these sheets combine durability, versatility, and aesthetic appeal. Below are the key benefits of using scratch-proof acrylic sheets:

- Low Maintenance: The scratch-resistant coating reduces the need for frequent cleaning or replacement, as the surface remains clear and undamaged longer. This protective film also helps prevent wear from dirt, dust, and everyday handling, making maintenance worry-free.

- Ease of Fabrication: Acrylic can be easily cut, drilled, and shaped without specialized tools, allowing for quick customization to fit specific project requirements. The smooth edges after cutting provide a professional finish and reduce the risk of injury.

- Aesthetic Versatility: With options for clear acrylic sheets, tinted, frosted, matte, or mirrored finishes, these sheets cater to both functional and decorative needs, enhancing the visual appeal of furniture, signage, menu boards, and display cases.

- Durability and Protection: Scratch proof acrylic sheets offer excellent abrasion resistance and high impact strength, providing long-term protection for surfaces exposed to frequent access and handling.

- Lightweight and Strong: Weighing about half as much as traditional glass, these sheets are easier to handle and install without compromising strength or clarity, making them ideal for a variety of indoor and outdoor applications.

- Cost-Effective: Compared to glass, acrylic sheets are more affordable, especially when factoring in their durability, lightweight nature, and lower maintenance costs, which can save money on repairs and replacements over time.

These benefits make scratch proof acrylic sheets a smart choice for projects requiring durable, clear, and attractive materials that stand up to daily wear and tear.

Considerations When Using Scratch Resistant Acrylic Sheet

While scratch-resistant acrylic sheets offer numerous advantages, there are a few important considerations to keep in mind to ensure optimal performance and longevity:

- Not Completely Scratch-Proof: Although the specialized coating significantly enhances scratch resistance, these sheets are not entirely impervious to damage. Heavy impacts, sharp objects, or intentional abrasion can still cause scratches or surface wear.

- Cleaning Requirements: To maintain the protective coating and clarity, always use soft, non-abrasive cloths and mild, acrylic-safe cleaners. Avoid harsh chemicals, abrasive pads, or solvents that can degrade the surface or reduce the scratch resistance over time.

- Thermal Sensitivity: Acrylic has a lower heat resistance compared to traditional glass, making it less suitable for environments exposed to high temperatures or direct heat sources. Excessive heat can cause warping or deformation.

- Static Build-Up and Dust Attraction: Acrylic sheets can accumulate static electricity, attracting dust and small particles. Regular gentle cleaning is necessary to keep the surface clear and maintain optimal visibility.

- Color and Coating Variations: Different manufacturers may offer various coatings and color options that affect scratch resistance and appearance. It’s important to verify product specifications and choose the right type for your specific application.

- Handling and Installation Tips: Proper handling during transport and installation is crucial to avoid edge chipping or surface damage. Always remove protective films carefully and avoid contact with sharp tools.

By considering these factors and following recommended care practices, you can maximize the durability and aesthetic appeal of scratch resistant acrylic sheets in your projects.

Conclusion

Scratch-resistant acrylic sheets are a game-changer in industries ranging from architecture to electronics, offering a perfect blend of durability, lightweight design, and aesthetic flexibility.

Their ability to resist scratches while maintaining optical clarity makes them an excellent choice for applications where appearance and longevity are paramount.

By understanding their properties and applications, businesses and designers can leverage these versatile materials to create innovative, long-lasting solutions that meet both practical and aesthetic needs.

If you’re looking for a reliable sheet material manufacturer, MUDUSA Acrylic is your top choice. As a leading professional plastic sheet manufacturing company in China, we specialize in high-quality acrylic products, including scratch-resistant sheets, cast acrylic panels, and custom-fabricated solutions.

Partner with MUDUSA Acrylic for excellence that stands the test of time—contact us today to elevate your projects.