Cutting ABS plastic sheets is a fundamental skill for many DIY enthusiasts, industrial fabricators, and hobbyists alike.

Whether you’re crafting custom parts for automotive applications, creating prototypes, or working on home projects, knowing how to cut ABS plastic sheet accurately and safely is essential.

This guide will walk you through the key techniques, tools, and safety measures to achieve clean edges and precise cuts, ensuring your finished product meets your specific needs and quality standards.

Understanding ABS Plastic Sheets

ABS plastic sheets are composed of acrylonitrile, butadiene, and styrene polymers, which give the material its unique combination of strength, toughness, and rigidity.

The presence of polybutadiene rubber enhances its impact resistance, making ABS ideal for applications requiring durability and resilience.

ABS has a relatively low melting point, typically between 105°C and 120°C, which affects how it should be handled during the cutting process to avoid melting or deformation.

The physical properties of ABS plastic sheets, such as their tensile strength and resistance to chemical corrosion, make them suitable for various industries, including automotive, electronics, and manufacturing.

Understanding these properties is crucial for selecting the right cutting methods and tools, as improper handling can compromise the integrity of the final product.

Tools and Materials Needed For Cutting ABS Sheet

To successfully cut ABS plastic sheets, having the right tools and materials is essential for achieving clean, precise cuts while maintaining safety and efficiency. Here are the key tools and materials commonly used:

Cutting Tools

- Jigsaw: Ideal for making both straight lines and curved cuts on ABS sheets. Use a fine-toothed blade designed specifically for plastics to ensure a smoother cut and reduce the risk of melting.

- Dremel Rotary Tool: Perfect for intricate designs and detailed cuts. Equip it with high-speed cutter bits or multipurpose cutting bits for optimal performance.

- Laser Cutter: Offers high precision and clean edges, especially for complex shapes and components. Adjust laser power and speed settings carefully to avoid melting or burning the plastic.

- Hot Knife: Useful for clean, sealed edges without sawdust. Requires steady control and is best used on thinner sheets.

- Table Saw: Effective for straight cuts when fitted with a plastic-cutting blade with a high tooth count to prevent chipping and melting.

Supporting Materials

- Clamps: Securely clamping the ABS sheet to a stable work surface is crucial for maintaining control and achieving accurate cuts.

- Protective Gear: Safety glasses, gloves, and masks protect against flying debris, dust, and fumes generated during cutting.

- Cooling Tools: An air gun or fan can help regulate temperature during cutting, preventing heat buildup that could cause melting or deformation.

- Measuring and Marking Tools: A ruler, straightedge, and fine-tip marker or scribing tool are important for marking precise cutting lines.

Work Surface Preparation

When working with ABS board, it is important to prepare the work surface properly by cleaning it with a damp cloth to remove dust and debris. This ensures better control during cutting and prevents imperfections on the edges.

Additionally, securely clamping the ABS sheet to the work surface helps maintain precision and safety throughout the cutting process.

By fine-tuning parameters like cutting speed, blade type, and cooling methods such as using an air gun, fabricators can achieve a smoother cut and protect the material from heat-related damage.

By combining the right tools, materials, and preparation, you can achieve optimal results when cutting ABS plastic sheets, whether for simple straight lines or intricate designs.

This foundation sets the stage for a smooth cutting process that aligns with the key aspects of modern manufacturing processes.

Cutting Methods For ABS Plastic Sheets

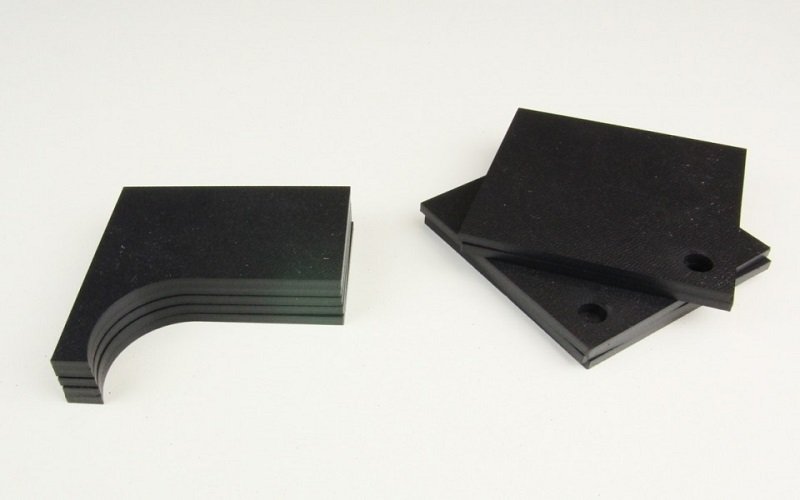

ABS plastic sheets can be processed using various traditional methods such as mechanical cutting, thermoforming, and die-cutting.

Cutting ABS plastic sheets requires selecting the appropriate method based on the sheet’s thickness, the complexity of the cut, and the tools available.

Below are detailed methods for cutting ABS plastic sheets, including step-by-step processes, tips, and comparisons to guide your approach.

Hand Scribing and Snap Cutting

For thinner ABS sheets, hand scribing followed by snapping along the score line is a simple and effective method. Use a sharp utility knife or plastic scribing tool to score a straight line on the sheet’s surface. Apply steady pressure and repeat the scoring several times to deepen the groove.

Then, firmly clamp the sheet and snap it along the scored line for a clean break. This method is best suited for straight cuts on thinner sheets and requires minimal equipment.

Using a Jigsaw for Curved Cuts

A jigsaw equipped with a fine-toothed blade designed for plastics is ideal for making both straight and curved cuts in ABS sheets. Begin by securely clamping the sheet to a stable work surface to prevent movement.

Mark your cutting line clearly with a fine-tip marker or scribing tool. Set the jigsaw to a moderate speed to avoid melting the plastic edges, and guide the blade steadily along the line without forcing it.

For curved cuts, take extra care to maneuver slowly to maintain control and precision.

Cutting With a Table Saw

For straight, long cuts, a table saw fitted with a high-tooth-count plastic cutting blade provides clean and efficient results. Ensure the ABS sheet is firmly clamped or supported to prevent vibrations.

Adjust the blade height to just above the thickness of the sheet and feed the material through the saw at a consistent pace.

Using a push stick can help maintain safety and control during the cutting process. Proper temperature control is essential to prevent melting or chipping of the edges.

Dremel Rotary Tool for Intricate Cuts

A Dremel rotary tool equipped with high-speed cutter bits or multipurpose bits is excellent for detailed and intricate cuts in ABS plastic sheets.

This tool allows for precision shaping and trimming of small parts or complex designs. Maintain a steady hand and moderate speed to avoid overheating the material.

It is recommended to make multiple shallow passes rather than attempting to cut through in one go to achieve smooth edges and avoid melting.

Hot Knife Cutting

A hot knife uses a heated blade to slice through ABS sheets, producing clean, sealed edges without sawdust or roughness. This method works best on thinner sheets and requires steady control to avoid overheating or burning the plastic.

Always operate a hot knife in a well-ventilated area to avoid inhaling fumes generated by melting plastic.

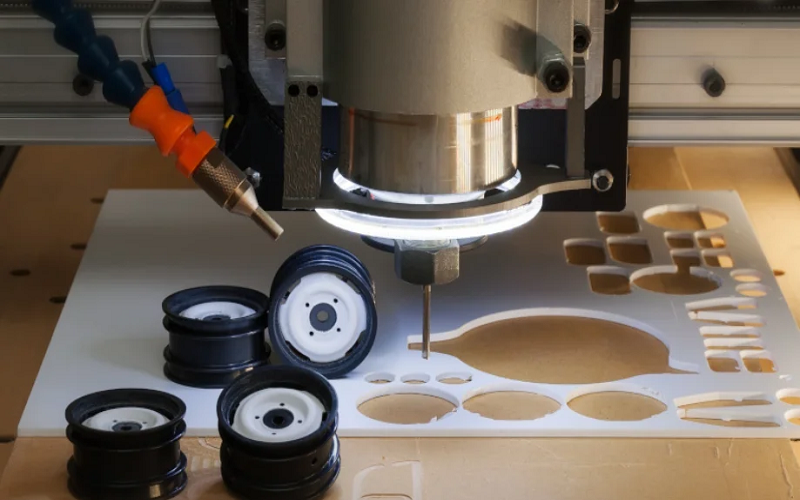

Laser Cutting Process

Laser cutting offers the highest precision and efficiency for cutting ABS plastic sheets, especially for complex shapes and industrial applications.

By fine-tuning parameters such as laser power, cutting speed, and focus, fabricators can achieve smooth, clean edges with minimal post-processing.

The non-contact nature of laser cutting reduces mechanical stress on the material and allows for intricate designs and high repeatability. Temperature control during laser cutting is critical to prevent melting or discoloration.

To enhance the surface finish further, consider using progressively finer grit sandpaper or advanced polishing techniques to achieve a smoother, higher-quality result.

Safety Precautions Of ABS Sheet Cutting Process

During the cutting process of ABS plastic sheets, special attention should be paid to the following safety precautions:

Equipment and Tool Maintenance

Before use, check that the blades, saw blades, and other accessories of laser cutting equipment are intact and properly installed. Regularly maintain the equipment and replace worn parts promptly to prevent safety accidents caused by equipment failure.

Operating Procedures

Strictly follow the operating procedures of the equipment. Maintain a stable cutting speed and pressure to avoid material breakage or equipment damage caused by excessive speed or force. Keep hands away from the cutting path, use push sticks or guide rails when operating table saws or band saws, and maintain a safe distance from the blade.

Material Handling

Ensure that the surface of the ABS sheet is clean and dry before cutting, free of oil or impurities, to avoid affecting cutting accuracy and surface quality. Secure the material firmly to prevent movement or slipping during cutting.

Proper Ventilation

Work in a well-ventilated area to disperse dust and gases, especially when using power tools or laser cutters, as heating ABS may release toxic vapors.

If operating indoors, use exhaust fans or open windows, and consider equipping smoke extraction systems during laser cutting or CNC machining. Avoid working in poorly ventilated enclosed spaces to reduce the risk of inhaling harmful substances.

Wearing Protective Equipment

When cutting ABS plastic sheets, it is essential to wear appropriate protective equipment to ensure safety.

Always use goggles or safety glasses to shield your eyes from flying debris, dust, or plastic fragments generated during cutting, especially when operating power tools like circular saws or jigsaws. Durable work gloves protect your hands from sharp edges, hot tools, and accidental slips.

Additionally, wearing dust masks or respirators is crucial to prevent inhalation of ABS dust or harmful gases, particularly when using power tools or laser cutters, as heating ABS can release potentially toxic styrene vapors.

Troubleshooting Common Issues In Cutting ABS Board

When cutting ABSplastic sheets, several common issues may arise, such as uneven cuts, material melting, or damage. These problems can compromise the quality of the cut and the final product.

By identifying the causes and implementing appropriate solutions, the cutting process can be optimized, waste reduced, and high-quality results achieved. Below are common issues and their troubleshooting methods.

1. Uneven Cuts or Jagged Edges

Uneven or jagged edges typically occur due to using an unsuitable blade or cutting too quickly. To prevent this, select a high-tooth-count blade designed for plastic cutting and maintain a steady, moderate cutting speed.

Additionally, ensure the ABS sheet is securely clamped to prevent vibration or movement during cutting, which helps achieve a smoother cut line.

If burrs or rough edges remain after cutting, use fine sandpaper or a file to gradually smooth the edges to a polished finish.

2. Material Melting or Deformation

Overheating during ABS cutting can cause the material to melt, stick, or deform, particularly when using power tools or laser cutters.

Slow cutting speeds lead to prolonged contact between the tool and material, generating excessive frictional heat, while overly high tool speeds can exacerbate heat buildup.

To avoid these issues, adjust power tools (e.g., circular saws or jigsaws) to a medium-low speed to reduce friction-induced heat.

Simultaneously, increase the cutting speed to shorten the blade’s contact time with the ABS sheet, while maintaining stability to ensure a smooth cut line.

3. Material Damage

During the cutting of thin ABS sheets (≤3mm), cracks or fractures may occur, especially when using the scoring and snapping method. This is often due to improper scoring depth, resulting in uneven stress during snapping.

To prevent this, use a sharp utility knife or scoring tool to make multiple light passes (3–5 times), ensuring the score depth is approximately half the sheet’s thickness. When snapping, apply slow and even pressure along the scored line to achieve a clean break, avoiding excessive or rapid force.

Summary

In summary, cutting ABS plastic sheets requires careful selection of the right tools and cutting techniques to ensure precise and high-quality results.

By thoroughly understanding the material properties, properly using the tools, and strictly following safety precautions, users can effectively avoid common issues such as uneven cuts or material melting.

Choosing the appropriate blade and controlling the cutting speed help address problems like jagged edges and material deformation, thereby improving cutting efficiency and the quality of the finished product.

We hope that through the above information, readers can better master the skills of cutting plastic sheets and achieve professional-grade results while minimizing material waste and ensuring safety.