In modern architecture, interior design, and industrial applications, various transparent or translucent sheet materials play a crucial role.

Among them, Frosted Polycarbonate Sheet, a specialized type of polycarbonate sheet(Lexan), stands out due to its unique surface treatment and exceptional performance.

This sheet material achieves light diffusion and privacy protection by applying a frosted texture to the surface of the polycarbonate substrate, while retaining the inherent advantages of polycarbonate.

This article will explore its characteristics and application scenarios, and compare it with acrylic sheet to help readers learn about the material secrets of this polycarbonate sheet.

Features Of Frosted Polycarbonate Sheet

Frosted Polycarbonate Sheet is a plastic sheet made from polycarbonate (PC) material, with a frosted finish achieved through a special process.

Polycarbonate itself is a high-performance engineering plastic, and the frosted finish lends it a unique visual and functional character. Here are its key features:

Impact Resistant and Durable

Polycarbonate plastic is renowned for its exceptional impact strength. With a tensile strength over 250 times greater than glass, polycarbonate sheets are virtually unbreakable and remain intact even under extreme conditions.

The frosted surface further enhances their scratch resistance, making them suitable for high-frequency use. This durable material provides robust protection against burglaries and vandalism while significantly reducing the risk of injury from broken glass.

Light Transmission with Privacy

The frosted surface scatters and diffuses light, providing soft, uniform illumination while obscuring visibility. This makes it ideal for applications requiring privacy without sacrificing natural light.

UV Protection

Many frosted polycarbonate sheets come with UV protection coatings on one or both sides, which help prevent yellowing and degradation from prolonged sun exposure, enhancing the sheet’s lifespan.

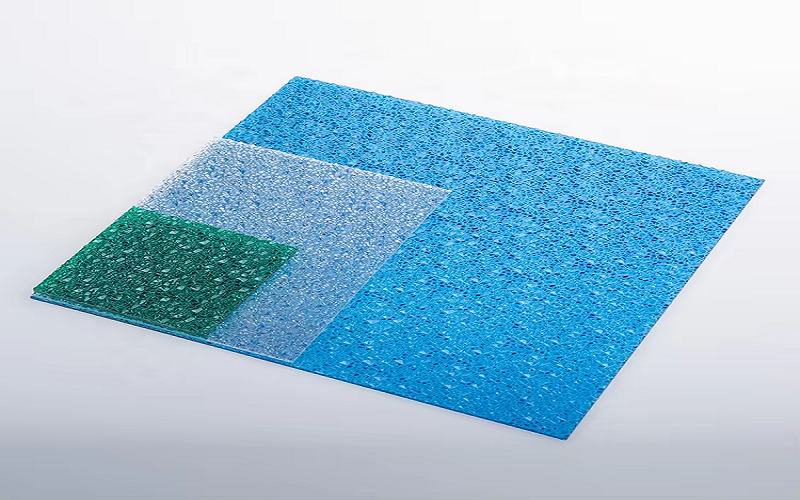

Versatile Sizes and Colors

These sheets are available in multiple colors such as clear, blue, green, yellow, and red, and come in a variety of thicknesses, widths, and lengths to suit different project requirements.

Pliable and Easy to Fabricate

Frosted polycarbonate sheets can be cut, sawn, drilled, routed, and formed with relative ease, allowing for custom fabrication to fit specific industrial, commercial, or residential needs. This simple fabrication process facilitates placing orders for custom sizes and shapes to match project specifications.

Thermal Insulation and Clarity

Despite the frosted finish, the sheets maintain good clarity and provide insulation properties that make them suitable for glazing, windows, office dividers, and machine guards.

Lightweight and Replacement Friendly

These plastic sheets are lighter than glass, reducing installation effort and cost. They are often sold as replacement panels for existing glazing or decorative installations.

In case of damage during shipping or installation, most manufacturers offer straightforward refund or replacement policies to ensure customer satisfaction.

Together, these features make frosted polycarbonate sheets an excellent choice for a wide range of applications, combining aesthetics, functionality, and durability.

How Thick Is Frosted Polycarbonate Sheet?

Frosted polycarbonate sheets come in a range of thicknesses to accommodate diverse application needs.

Common thickness options typically range from 1.5 mm to 12 mm, with 2 mm, 4 mm, 6 mm, and 8 mm being popular choices for most commercial and residential projects.

Thinner sheets, such as 1.5 mm or 2 mm, are often used where flexibility and lightweight properties are essential, such as in decorative panels or light diffusers.

Thicker sheets, like 6 mm to 12 mm, provide enhanced durability and impact resistance, making them suitable for applications requiring greater strength, such as machine guards, roofing, or protective barriers.

When selecting the appropriate thickness, it is important to consider factors such as the desired level of insulation, structural strength, and the type of installation.

Manufacturers often provide frosted polycarbonate sheets in standard sizes but can also offer custom thicknesses and larger sheets upon request. This flexibility allows architects, designers, and builders to select the perfect material specifications that meet both aesthetic and functional demands.

What Are Frosted Polycarbonate Plastic Sheets Used For?

Due to its unique privacy and light-diffusion properties, many plastic sheet manufacturers choose frosted polycarbonate sheet for applications in building, interior design, and industrial settings. Below are common use cases:

- Office Dividers and Privacy Screens: The frosted surface provides privacy while allowing natural light to pass through, making it ideal for creating partitions in offices, conference rooms, and coworking spaces.

- Shower Enclosures and Bathroom Partitions: Its water resistance, impact strength, and privacy features make it a popular choice for modern bathroom designs.

- Skylights and Roofing Panels: Frosted polycarbonate sheets offer excellent light transmission with UV protection, providing soft, diffused daylight while shielding interiors from harmful rays.

- Machine Guards and Safety Barriers: The durability and impact resistance protect workers and equipment in industrial environments without compromising visibility.

- Signage and Display Cases: Available in multiple colors and sizes, these sheets are used for eye-catching signs and protective display covers.

- Greenhouse Panels: Their insulation properties and light diffusion help create optimal growing conditions by evenly distributing sunlight.

- Carports and Patio Covers: Lightweight yet strong, frosted polycarbonate sheets provide weather-resistant shelter with a pleasant, softened light effect.

These versatile applications highlight the material’s adaptability, combining aesthetics with practical performance across various industries.

The Difference Between Frosted Polycarbonate Sheet And Acrylic Sheet

Acrylic sheets are another common type of clear plastic sheet, often available in frosted versions (Frosted Acrylic sheet).

Although both have a similar appearance and can achieve light diffusion effects, the materials differ fundamentally, resulting in significant differences in performance and suitability. The comparison is as follows:

Strength and Impact Resistance

Frosted Polycarbonate Sheet offers impact resistance far superior to acrylic, being 250 times stronger than glass, while acrylic is only 10-17 times stronger than glass.

Polycarbonate is less prone to breaking, making it suitable for high-risk environments like public spaces; acrylic is more brittle, prone to scratching but has a smoother surface.

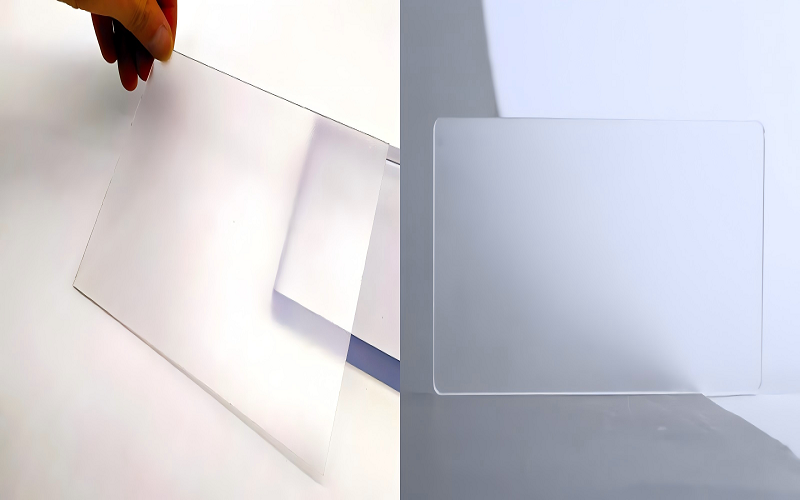

Light Transmission and Clarity

Both have frosted surfaces that provide privacy and diffuse light, but acrylic in its non-frosted state has a light transmission rate as high as 92%, closer to the clarity of glass.

Polycarbonate’s frosted effect is more uniform, but its overall transparency is slightly lower, making it better suited for applications emphasizing privacy.

Weather Resistance and Temperature Adaptability

Polycarbonate performs better under low temperatures (less prone to becoming brittle) and temperature fluctuations, making it suitable for outdoor or extreme weather conditions.

Acrylic has excellent UV resistance against yellowing but tends to deform under high temperatures and is more brittle in cold environments.

Fabrication and Cost

Acrylic is more cost-effective, being approximately 35% less expensive than polycarbonate, and is easier to cut, bond, and thermoform, with excellent surface polishability for a refined finish.

In contrast, polycarbonate demands specialized tools to prevent scratching during processing, which may increase initial costs.

However, its superior fire resistance and exceptional durability make it a more economical choice over time, saving money on replacements and maintenance in demanding applications.

Application Preferences

Frosted Polycarbonate Sheet is more suitable for scenarios requiring high safety and impact resistance, such as industrial or public buildings; Frosted Acrylic tends to be favored for decorative, budget-conscious indoor designs like furniture or display cases.

Overall, the choice depends on specific needs: if safety and durability are priorities, polycarbonate sheets are preferred; if optical aesthetics and cost-effectiveness are the focus, acrylic sheets are more appropriate.

Conclusion

Frosted polycarbonate sheet is a versatile material widely used in both commercial and residential applications due to its excellent impact resistance, superior light transmission, and durable UV protection.

This innovative plastic sheet combines the strength of polycarbonate plastic with a unique frosted finish that provides privacy while allowing soft, diffused light to pass through.

When placing an order, please note that you can specify the contact details and desired quantity to ensure your custom sizes or multiple colors are accurately fulfilled.