Marine plastic sheets have become indispensable materials in the marine industry, offering unmatched durability, versatility, and resistance to harsh marine environments.

This guide provides a comprehensive overview of marine plastic sheets, highlighting their superior flatness, consistent color, UV resistance, and ease of fabrication with standard woodworking tools.

What Are Marine Plastic Sheets?

Marine plastic sheets are specially engineered materials designed to withstand the tough marine environments encountered on boats, ships, and other watercraft.

These sheets are typically made from high density polyethylene (HDPE), also known as marine grade HDPE, which offers exceptional tensile strength, UV resistance, and water absorption properties.

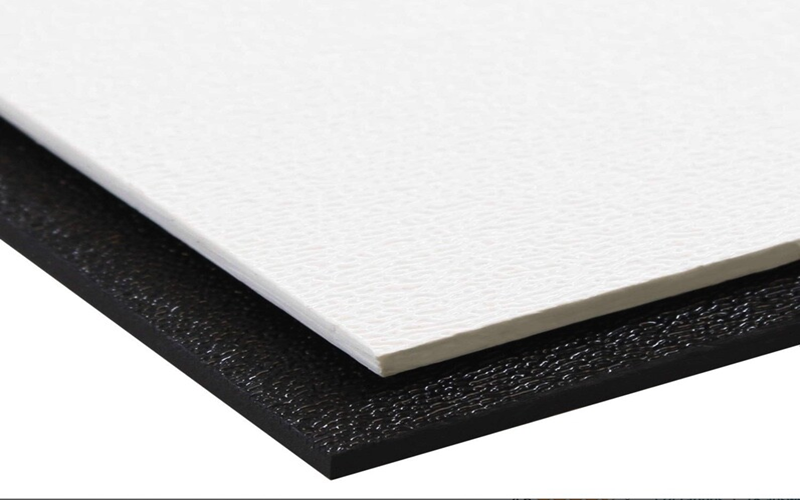

Featuring a durable matte textured surface and consistent color, marine plastic sheets are environmentally stabilized to resist rot, rust, and prolonged sun exposure.

They are easy to fabricate using common woodworking tools, forming smooth curves and clean edges with little or no finishing required.

Types Of Marine Plastic Boards

Marine plastic boards come in various types, each offering unique benefits for different marine applications.

Each type of marine plastic board is manufactured using the most advanced manufacturing process to ensure precise tolerances, clean edges, and consistent thickness, allowing experienced boat builders to choose the finest polymers for their projects.

Marine Grade HDPE Sheet

Known for their exceptional durability and UV resistance, these sheets are the industry standard for boat components, seating components, and instrument panels.

They feature a durable matte finish, consistent color, and are easy to fabricate with standard woodworking tools.

Acrylic Sheet

Offering excellent optical clarity and impact strength, acrylic sheets are commonly used for boat windows, windshields, and protective glazing.

They resist harsh sun exposure and maintain safety and visibility.

Polycarbonate Sheet

These sheets provide superior impact strength and chemical resistance, ideal for marine enclosures and heavy-duty applications.

Their toughness makes them suitable for dock fenders and protective hull components.

PVC Sheet

Lightweight and weather-resistant, marine-grade PVC is often used for upholstery, backing plates, and rod holders.

Its resistance to mold and mildew helps reduce maintenance costs in wet environments.

UHMW-PE Sheet

Ultra-high molecular weight polyethylene sheets offer outstanding wear resistance and low friction, making them perfect for applications requiring long-term durability such as rails and lift bushings.

Properties Of Marine Grade Plastics Sheet

Marine grade plastics sheets possess a range of exceptional properties that make them ideal for marine applications.

UV Resistant

These sheets are engineered to withstand prolonged sun exposure without degrading or losing color, ensuring long-lasting performance in harsh marine environments.

Their color accuracy remains consistent over time, even under the toughest UV radiation, which helps maintain the aesthetic appeal of boats and marine components.

This makes them ideal for DIY projects and professional applications alike, especially when replacing wood or metal parts exposed to the elements.

Chemical Resistance

These sheets do not absorb water and resist a wide range of chemicals, effectively preventing rot, rust, and corrosion even in the most demanding wet and salty marine environments.

Their excellent chemical resistance ensures long-lasting durability and minimal maintenance costs, making them a reliable choice for various marine applications.

Environmentally Stabilized

Designed to resist harsh sun, sea, and weather conditions, these marine plastic sheets maintain their integrity without warping, delaminating, or fading.

Their protective masking during shipping ensures clean edges finish cleanly, making them easy to handle and install.

Available in custom sheet sizes, these durable sheets vary considerably in thickness and color options, allowing boat builders to choose King Starboard or other premium marine board materials.

Applications Of Marine Plastic Sheets

Marine plastic sheets are highly versatile and widely used across various marine applications due to their durability and resistance to harsh environments.

Boat Components

Used extensively for fabricating seating components, instrument panels, and protective hull parts, marine plastic sheets provide long-lasting performance with excellent resistance to rot, corrosion, and water absorption.

Their durable matte textured surface and UV resistance ensure they withstand prolonged sun exposure and harsh marine environments, reducing maintenance costs and extending the lifespan of boat components.

Dock Fenders

Their superior impact strength and low friction make them ideal for dock fenders and rails, significantly reducing wear and maintenance costs while enhancing safety and durability in tough marine environments.

Maintenance And Care Of Marine Plastic Sheets

Proper maintenance and care are essential to maximize the lifespan and performance of marine plastic sheets.

These durable materials require minimal upkeep, but regular cleaning helps preserve their UV resistance and consistent color.

Use mild detergents and water to clean the surface, avoiding harsh chemicals that could damage the protective matte finish.

For stubborn stains or marks, diluted bleach solutions or non-abrasive cleaners are effective without compromising the sheet’s integrity.

Additionally, marine plastic sheets benefit from routine inspections to check for scratches or damage, which can often be easily repaired or polished.

Applying a protective coating or marine-grade polish occasionally can enhance the appearance and further protect against prolonged sun exposure and harsh marine conditions.

With proper care, marine plastic sheets will continue to form easily, maintain smooth curves, and provide reliable performance for boat components and other marine applications.

Conclusion

Marine plastic sheets have revolutionized the marine industry by providing durable, versatile, and low-maintenance materials that withstand the toughest marine environments.

By choosing high-quality marine grade plastics such as marine HDPE sheets, boat builders and DIY enthusiasts can ensure long-lasting performance and reduced maintenance costs.

Available in large sheets and custom sheet sizes, these marine plastic boards offer unmatched convenience and reliability, whether purchased individually or through a convenient cart buy option.

They often feature a durable matte textured surface on one side for enhanced aesthetics and functionality.

This ultimately enhances the safety, aesthetics, and durability of marine vessels while providing consistent color and clean edges that vary considerably less than other materials, even when viewed on computer monitors during selection.