Vacuum forming plastic sheet is a versatile and cost-effective manufacturing process widely used across various industries to create custom plastic parts and products.

This technique involves heating a plastic sheet until it becomes pliable, then using vacuum pressure to form it over a mold, resulting in precise and durable components.

In this article, we will explore the vacuum forming plastic sheet process, its applications, advantages, providing a comprehensive overview for anyone interested in this essential manufacturing method.

What Is Vacuum Forming?

Vacuum forming is a popular manufacturing process used to shape a vacuum forming plastic sheet into custom parts and products.

It involves heating a plastic sheet until it becomes soft and pliable, then stretching it over a mold. Using vacuum pressure, air is removed from between the sheet and the mold, causing the plastic to tightly conform to the mold’s shape.

This cost effective alternative to other manufacturing processes is widely used in commercial applications and by small businesses alike.

Vacuum forming offers advantages such as faster production process times, the ability to produce large parts and complex shapes, and reduced costs compared to injection molding.

Types Of Vacuum Forming Plastic Sheets

Vacuum forming plastic sheets come in a variety of materials, each offering unique benefits suited to different applications.

Acrylic (PMMA) Sheet

Acrylic, also known as PMMA (Polymethyl methacrylate), is a highly versatile vacuum forming plastic sheet prized for its excellent clarity and high impact strength.

It is frequently used in applications requiring a transparent and aesthetically pleasing finish, such as display cases, signage, and medical packaging.

Acrylic sheets are easy to thermoform into intricate shapes while maintaining a smooth surface, making them ideal for creating both functional and decorative components.

Polyvinyl Chloride (PVC) Sheet

Polyvinyl Chloride is a widely used vacuum forming plastic sheet known for its excellent chemical resistance, durability, and flame retardant properties.

It is a versatile material suitable for manufacturing large parts and components that require robustness and longevity.

PVC sheets can be easily formed using vacuum forming machines, making them ideal for producing household items, medical packaging, and protective equipment.

High Impact Polystyrene (HIPS) Sheet

High Impact Polystyrene (HIPS) is a popular vacuum forming plastic sheet known for its excellent balance of rigidity and impact resistance.

This material is lightweight yet durable, making it ideal for producing a wide range of products such as food packaging, trays, disposable containers, and point-of-purchase displays.

HIPS offers a low cost solution without compromising on strength, and it forms easily under vacuum pressure, allowing for precise and consistent finished parts.

Polyethylene Terephthalate Glycol (PETG) Sheet

Polyethylene Terephthalate Glycol, commonly known as PETG, is a highly versatile vacuum forming plastic sheet valued for its excellent clarity, toughness, and food-safe properties.

PETG is commonly used in applications requiring transparency and durability, such as food storage containers, medical packaging, and retail displays.

Its superior formability allows it to be easily shaped using vacuum forming machines, producing precise and consistent parts with smooth finishes.

Process Of Vacuum Forming

The vacuum forming process involves several key steps to transform a plastic sheet into a desired shape with precision and efficiency.

Heating The Plastic Sheet

In the vacuum forming process, heating the plastic sheet is a crucial step that determines the quality and accuracy of the final product.

The plastic sheet is securely clamped into the vacuum forming machine and evenly heated until it reaches the optimal pliable temperature.

Forming Over The Mold

During the forming stage of the vacuum forming process, the heated and pliable plastic sheet is carefully positioned over the mold.

The vacuum forming machine then activates the vacuum pressure, which rapidly removes the air between the plastic sheet and the mold surface.

This suction effect pulls the plastic tightly against the mold, ensuring that even the smallest details and contours are accurately replicated.

Cooling

Cooling is a vital step in the vacuum forming process that ensures the plastic sheet retains the precise shape of the mold.

After the plastic is formed, it must be cooled sufficiently to solidify and maintain its structural integrity.

Proper cooling not only helps prevent warping and distortion but also reduces cycle times, enabling faster future production and improved efficiency in mass production environments.

Releasing And Trimming

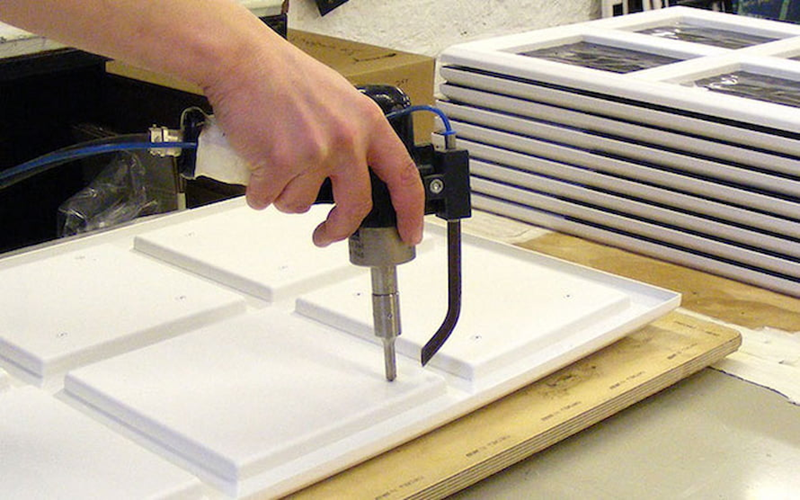

Once the plastic sheet has cooled and solidified, the next crucial step in the vacuum forming process is releasing the formed part from the mold.

After removal, any excess plastic, often referred to as flash, is trimmed away using specialized cutting tools or CNC machines.

Efficient releasing and trimming not only improve the overall finish of the vacuum formed plastic parts but also help reduce material waste, making the manufacturing process more cost-effective and environmentally friendly.

Applications Of Vacuum Forming Plastic Sheets

Vacuum forming plastic sheets are widely used across various industries due to their versatility and cost-effectiveness.

Automotive Industry

In the automotive industry, vacuum forming plastic sheets plays a crucial role in manufacturing durable, lightweight, and cost-effective components.

This process is commonly used to produce interior panels, dashboards, door trims, and protective covers that not only enhance the vehicle’s aesthetic appeal but also contribute to reducing overall weight, improving fuel efficiency.

Packaging

Vacuum forming plastic sheets is extensively used in the packaging industry to create custom food packaging, trays, clamshells, and blister packs.

This manufacturing process allows for the production of lightweight, durable, and visually appealing packaging solutions that protect products during transportation and display.

Medical Sector

The medical sector greatly benefits from vacuum forming plastic sheets due to the process’s ability to produce sterile, precise, and cost-effective components.

Vacuum forming is widely used to create medical packaging, such as blister packs and trays, that ensure hygiene and protect sensitive instruments and pharmaceuticals.

Industrial Applications

Vacuum forming plastic sheets is extensively utilized in various industrial sectors due to its ability to produce large, durable parts efficiently and cost-effectively.

This manufacturing process is ideal for creating protective covers, housings, and panels used in heavy machinery, agricultural equipment, and electronic devices.

Industrial vacuum forming machines enable high precision and consistency, making it possible to produce parts that meet strict industry standards.

Household Items

Vacuum forming plastic sheets is a popular method for producing a wide range of household items due to its cost effectiveness and versatility.

Many everyday products such as kitchenware, storage containers, bathroom fixtures, and decorative items are created using this manufacturing process.

The ability to shape durable and lightweight plastic parts quickly makes vacuum forming ideal for household applications.

Future Outlook Of Vacuum Forming Plastic Sheet

The future of vacuum forming plastic sheet technology looks promising as advancements continue to enhance its efficiency, versatility, and sustainability.

With increasing demand for cost effective alternative manufacturing processes, vacuum forming is expected to play a vital role in producing custom parts across various industries.

Innovations such as the integration of diy vacuum forming machines make this technology more accessible to small businesses and hobbyists, expanding its reach beyond traditional industrial applications.

As vacuum forming continues to evolve alongside other thermoforming processes like pressure forming and injection molding, it will remain an essential manufacturing process for creating durable, cost-effective, and customizable plastic parts in the years to come.

Conclusion

Vacuum forming plastic sheet is a highly efficient and versatile manufacturing process that offers numerous advantages across various industries.

Its ability to produce precise, durable, and cost-effective plastic parts makes it an ideal choice for applications ranging from automotive components to medical packaging and household items.

By utilizing industrial vacuum forming machines or diy vacuum forming machines, manufacturers and small businesses alike can benefit from faster production times, reduced costs, and design flexibility.

As technology advances, vacuum forming continues to evolve, providing a sustainable and scalable solution for both large production runs and custom parts.

Embracing vacuum forming as a manufacturing process not only helps reduce material waste through efficient air removal and excess plastic management but also supports innovation in creating products with complex shapes and high impact strength.

Overall, vacuum forming remains a vital process in modern manufacturing, combining affordability, adaptability, and quality to meet the demands of today’s market.