Heavy duty plastic sheets are essential materials widely used across various industries due to their durability, versatility, and resistance to harsh conditions.

Whether for construction, industrial applications, or everyday storage needs, these sheets provide reliable protection against moisture, chemicals, and physical wear.

In this article, we will explore the key features, types and applications, helping you choose the right plastic sheeting for your specific project.

What Are Heavy Duty Plastic Sheets?

Heavy duty plastic sheets are thick, durable sheets made primarily from high density polyethylene (HDPE) or similar materials designed to withstand tough industrial and construction environments.

These sheets offer excellent resistance to moisture, chemicals, and physical damage, making them ideal for applications such as vapor barriers, protective coverings, and storage liners.

Whether you need black, white, or clear plastic rolls, these sheets are engineered to resist breakdown from UV exposure and offer long-lasting protection in flat installations, exposed vertical surfaces, and underground applications.

Types Of Heavy Duty Plastic Sheets

Understanding the different types of heavy duty plastic sheets is crucial for selecting the right material that meets the specific demands of your project.

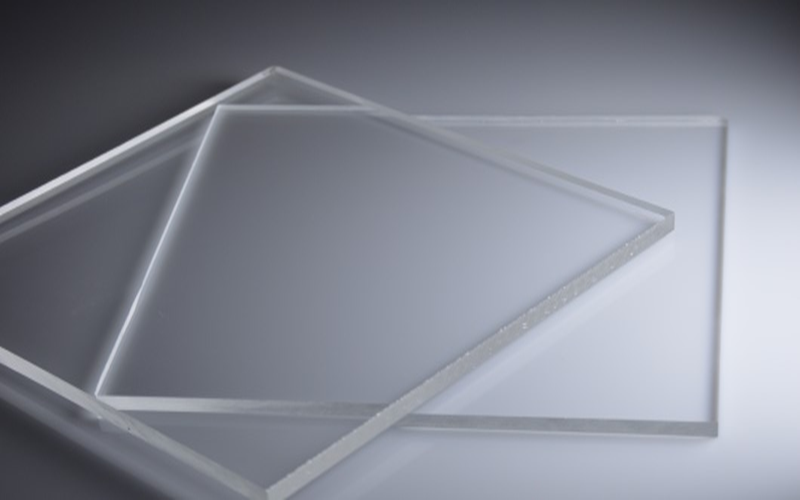

High Density Polyethylene (HDPE) Plastic Sheet

High Density Polyethylene sheets are a top choice for heavy duty plastic sheets due to their exceptional strength, durability, and versatility.

Manufactured with a high density polyethylene texture, these sheets provide a rigid HDPE structure that performs well in both industrial and residential applications.

HDPE sheets are available in various material widths and thicknesses, allowing you to choose the right plastic sheeting tailored to your specific needs.

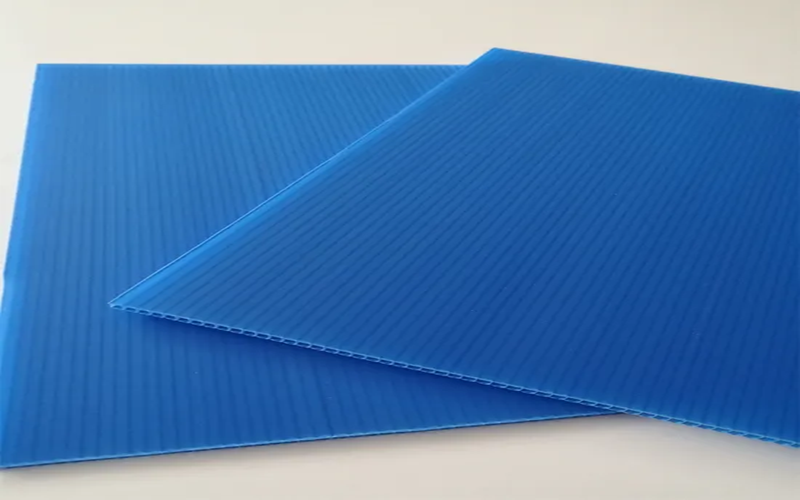

Low Density Polyethylene (LDPE) Plastic Sheet

Low Density Polyethylene sheets are a versatile option within heavy duty plastic sheets, prized for their flexibility and excellent impact resistance.

This makes LDPE sheets ideal for applications requiring cushioning or wrapping, such as protective packaging, liners, and drop cloths.

Despite being lightweight, LDPE sheets maintain durability and resistance to moisture and chemicals, making them suitable for a wide range of industrial and residential uses.

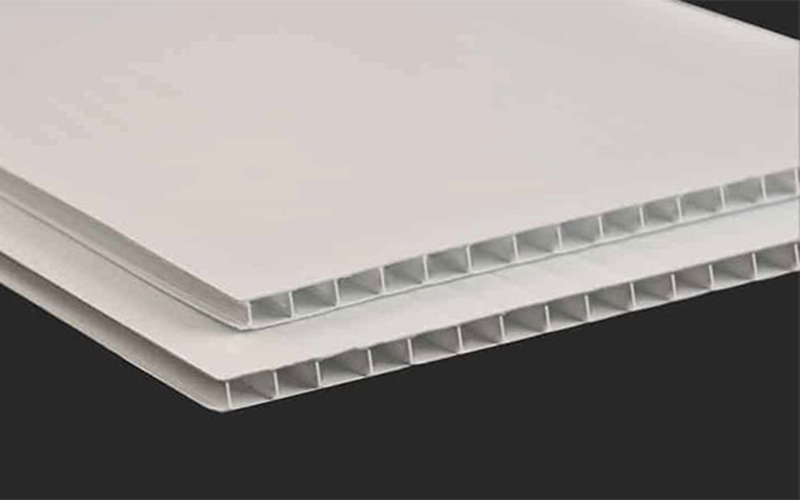

Polyvinyl Chloride (PVC) Plastic Sheet

Polyvinyl Chloride sheets are a popular choice among heavy duty plastic sheets due to their outstanding chemical resistance and robust durability.

PVC offers a rigid yet versatile material that can withstand exposure to harsh chemicals, oils, and weather conditions, making it ideal for demanding industrial applications.

These sheets provide excellent protection in environments where corrosive substances are present, such as in piping, containment systems, and protective barriers.

Characteristics Of Heavy Duty Plastic Sheets

Heavy duty plastic sheets possess several key characteristics that make them indispensable in various applications.

Durability

Durability is a defining feature of heavy duty plastic sheets, making them a reliable choice for demanding applications.

These sheets are engineered to resist punctures, tears, and abrasions, ensuring they maintain their integrity even under harsh conditions.

The high density polyethylene (HDPE) plastic thickness plays a crucial role in enhancing this durability, providing a sturdy yet flexible barrier that withstands physical stress.

Versatility

Heavy duty plastic sheets are incredibly versatile, making them suitable for a broad spectrum of applications across various industries.

Whether you need to connect multiple pieces for large-scale projects or require sheets that can handle both exposed installations and underground installations, these plastics adapt seamlessly.

Their versatility extends to applications in children’s toys, packaging, and other containers, highlighting their importance in both industrial and everyday uses.

Thickness Options

Heavy duty plastic sheets come in a variety of thicknesses, typically measured in mils (thousandths of an inch), to suit different project requirements.

Thicker sheets offer enhanced protection against punctures, tears, and harsh environmental conditions, making them ideal for high traffic areas and heavy-duty industrial uses.

Choosing the correct thickness ensures a more water resistant connection and a longer-lasting barrier, especially in underground installations or exposed vertical surfaces where durability is critical.

UV Resistance

One of the standout features of heavy duty plastic sheets is their excellent UV resistance.

Many of these sheets are treated with built-in UV inhibitors that significantly reduce the risk of material breakdown when exposed to prolonged sunlight.

This UV resistance ensures that the plastic retains its strength, flexibility, and color over time, making it ideal for both outdoor and indoor applications.

Water Resistance

Heavy duty plastic sheets are designed to provide exceptional water resistance, making them ideal for use as moisture barriers in a variety of applications.

This property is crucial for both ground installation and below ground installation, where preventing moisture intrusion protects structures from damage, inhibits mold growth, and guards against plant root intrusion.

Additionally, the large overlap area used when connecting multiple pieces with double sided seam tape further enhances the water resistant connection, ensuring a secure barrier that stands up to harsh environmental conditions over time.

Manufacturing Process Of Heavy Duty Plastic Sheets

The manufacturing process of heavy duty plastic sheets involves advanced techniques to ensure durability, consistency, and performance.

Typically, high density polyethylene (HDPE) pellets are melted and extruded through specialized machinery that forms the plastic into continuous sheets or rolls.

During extrusion, additives such as UV inhibitors and stabilizers are incorporated to enhance resistance to sunlight and environmental factors, preventing premature breakdown.

The sheets are then cooled and rolled onto spools, with precise control over thickness and material width to meet specific project requirements.

Manufacturers often provide custom roll lengths and offer an extensive selection of thicknesses and colors, including black and white colors, to suit diverse applications.

Quality control measures ensure that each sheet maintains a high density polyethylene texture and meets industry standards for strength, puncture resistance, and water resistance, making them ideal for both exposed installations and buried applications.

Applications Of Heavy Duty Plastic Sheets

Heavy duty plastic sheets have a wide range of applications across various industries due to their strength and versatility.

Construction

Heavy duty plastic sheets are indispensable in construction projects, serving as reliable vapor barriers and moisture barriers that protect buildings from water damage and contamination.

These sheets also help guard against plant root intrusion and provide a secure connection that withstands high traffic areas and harsh environmental conditions.

With options to choose material width and thickness, construction professionals can select the right plastic sheeting that fits their project needs, ensuring a solid connection and preventing potential catching on ridges exposed by seams.

Agriculture

Heavy duty plastic sheets are widely used in agriculture to enhance crop production and protect valuable resources.

These sheets serve as greenhouse covers, creating controlled environments that optimize temperature and humidity for plant growth.

They are also commonly employed as silage bags, preserving animal feed by preventing spoilage and maintaining nutritional quality.

Industrial

Heavy duty plastic sheets are extensively used in industrial settings due to their exceptional chemical resistance and durability.

These sheets are ideal for lining containment areas, protecting machinery, and creating barriers that prevent contamination and chemical spills.

Their robust nature ensures they withstand harsh industrial environments, including exposure to oils, solvents, and other corrosive substances.

Packaging

Heavy duty plastic sheets play a crucial role in packaging by providing durable liners and protective wraps for heavy or sensitive goods.

Their toughness and resistance to moisture, chemicals, and physical damage ensure that products remain secure during transport and storage.

These sheets help prevent contamination, punctures, and tears, maintaining the integrity of packaged items.

How To Use Heavy Duty Plastic Sheeting?

Using heavy duty plastic sheets effectively requires understanding the specific needs of your project and choosing the right type and thickness of plastic sheeting.

Start by measuring the area where the sheets will be installed to ensure you purchase the correct material width and length.

When installing HDPE plastic sheets, it is important to connect multiple pieces securely using methods such as the overlap method or the end method.

The overlap method involves overlapping two pieces and sealing them with double sided seam tape, providing a more water resistant connection ideal for underground installations.

The end method, on the other hand, butts two pieces together and uses seam tape to create a solid connection without exposed ridges, making it suitable for exposed vertical or flat installations where object catching could be a concern.

Proper installation ensures a durable, water resistant barrier that protects against moisture, chemicals, and physical damage.

Additionally, selecting the right thickness based on a thickness comparison helps optimize performance for high traffic areas or heavy duty industrial applications.

Whether used for construction, agriculture, or industrial purposes, following these installation guidelines will maximize the effectiveness and lifespan of your heavy duty plastic sheets.

Conclusion

Heavy duty plastic sheets are indispensable materials that offer unmatched durability, versatility, and protection across a wide range of applications.

Many suppliers offer rigid HDPE options, allowing you to select the ideal material stiffness for your project needs.

When installing HDPE pieces, one method commonly used is the overlap method with double sided seam tape, which provides a more water resistant connection ideal for underground installations.

The other method, known as the end method, creates a solid connection without ridges exposed, making it perfect for exposed vertical or flat installations where potential catching on ridges could be a concern.

High imp resistance is another critical feature of heavy duty plastic sheets, ensuring they withstand physical wear and tear in demanding environments.

Additionally, HDPE sheets are recyclable, making them an environmentally responsible choice for sustainable projects.

For your convenience, many suppliers provide custom roll lengths and an extensive selection of material widths and colors. Be sure to shop for related products such as seam tapes and installation accessories to complete your project efficiently.

Whether used as a vapor barrier on a wall or as a protective cover in industrial settings, heavy duty plastic sheets deliver secure, durable protection that meets high performance standards.