Waterproof plastic sheets play a vital role across a wide range of industries, providing essential protection against moisture, chemicals, and environmental elements.

Their waterproofing capability ensures durability and reliability, making them indispensable in construction, agriculture, packaging, and manufacturing sectors.

This comprehensive guide aims to explore the various types of waterproof plastic sheets, their key properties, common applications, and important criteria to consider when selecting the right material for your specific needs.

What Are Waterproof Plastic Sheets?

Waterproof plastic sheets are specially designed materials that provide a reliable barrier against water and moisture.

Made from high-quality plastics such as high density polyethylene (HDPE), these sheets offer excellent resistance to tearing, rot, rust, and various chemicals, making them ideal for continuous use in both commercial and residential applications.

Their surface is engineered to withstand exposure to different temperatures and UV rays, ensuring long-lasting durability even when exposed outdoors.

Available in a range of thicknesses and both transparent and opaque options, waterproof plastic sheets can be easily installed and are often shipped from regional warehouses with efficient transit times, typically counted in business days.

These versatile sheets protect surfaces, prevent liquid penetration, and help save money by reducing maintenance and replacement costs. Manufactured in the USA, they qualify as an ideal product for various applications where water resistance is essential.

Types Of Waterproof Plastic Sheets

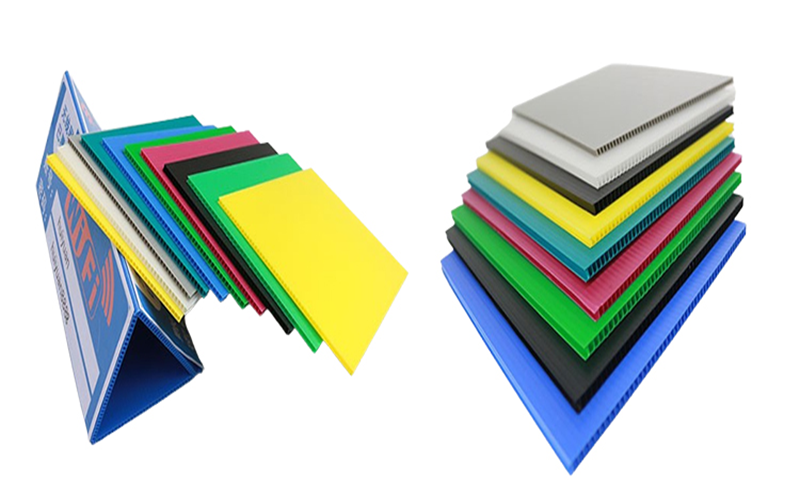

Waterproof plastic sheets come in various types, each tailored to specific applications and performance needs.

High Density Polyethylene (HDPE) Sheet

High Density Polyethylene sheets are among the most popular choices for plastic sheet waterproof applications due to their outstanding durability and resistance to moisture.

Manufactured from high-quality thermoplastic polymer, HDPE offers excellent protection against water, chemicals, and UV radiation, ensuring long-lasting performance even when exposed to harsh outdoor environments.

Additionally, HDPE orders typically ship quickly from regional warehouses, with transit times displayed as approximate business days, ensuring timely delivery.

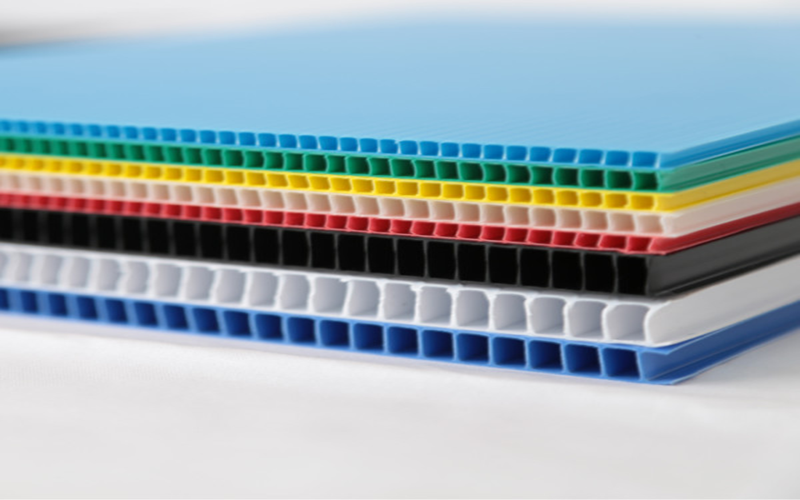

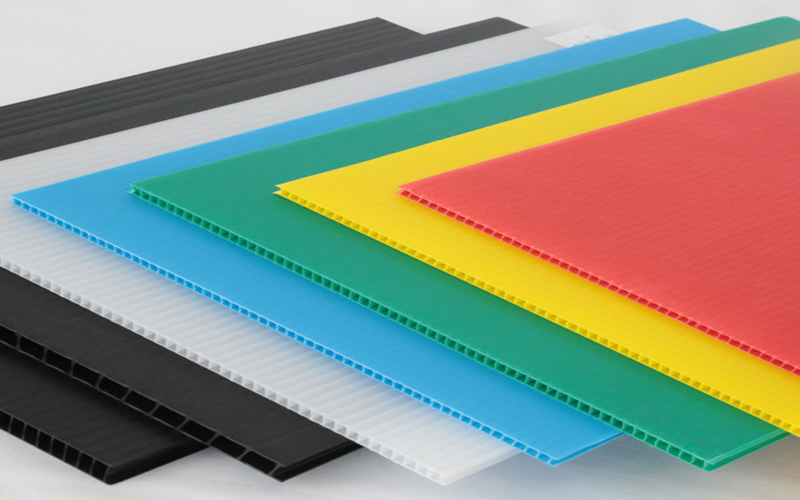

Polyvinyl Chloride (PVC) Sheet

Polyvinyl Chloride (PVC) sheets are a versatile and cost-effective option in the range of waterproof plastic sheets.

These sheets are designed to withstand continuous exposure to water without degrading, and their surface is often treated to provide UV protection, enhancing durability when used outdoors.

Additionally, they are available in various thicknesses and can be sourced from regional warehouses with efficient stock levels and transit times, typically counted in business days.

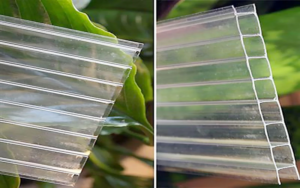

Polycarbonate (PC) Sheet

Polycarbonate (PC) sheets are a premium choice in the realm of plastic sheet waterproof solutions, offering exceptional strength and durability.

Known for their high impact resistance, these sheets can withstand harsh environmental conditions without cracking or breaking.

Polycarbonate sheets are also UV stabilized, providing reliable protection against sun damage and ensuring long-lasting performance when exposed outdoors.

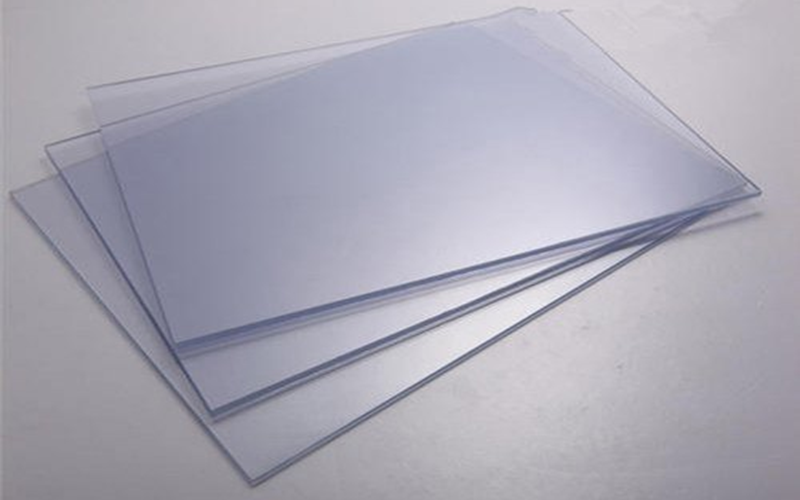

Acrylic Sheet

Acrylic sheets are a popular choice in waterproof plastic sheets due to their excellent clarity, weather resistance, and durability.

These sheets provide a hard, scratch-resistant surface that maintains transparency even after prolonged exposure to sunlight, thanks to their UV protection properties.

Acrylic sheets are ideal for outdoor applications such as signage, windows, protective barriers, and display cases where both waterproofing and aesthetic appeal are important.

Flexible Vinyl Sheet

Flexible vinyl sheets are an excellent option within the range of plastic sheet waterproof materials, offering both durability and adaptability.

These sheets are made from high-quality vinyl that provides superior water resistance while remaining pliable enough to conform to various shapes and surfaces.

They are easy to install and maintain, making them a practical choice for both commercial and residential projects requiring reliable waterproofing solutions.

Key Properties Of Plastic Sheet Waterproof

When selecting a plastic sheet waterproof material, several key properties ensure optimal performance and durability.

Water Resistance

Water resistance is the most critical attribute of plastic sheet waterproof materials.

These sheets are engineered to create an impermeable barrier that effectively prevents water from passing through, protecting underlying surfaces and structures from moisture damage.

Whether used in construction, agriculture, or packaging, their ability to hold back water ensures that items remain dry and intact even in harsh weather conditions.

Durability

Durability is a crucial factor when choosing plastic sheet waterproof materials.

These sheets are engineered to resist wear and tear from daily use and environmental exposure. They offer excellent resistance to punctures, tears, and abrasions, ensuring they maintain their protective qualities over time.

UV Protection

UV protection is a vital feature of plastic sheet waterproof materials, especially for outdoor applications.

Many waterproof plastic sheets are specially treated with UV inhibitors that shield the material from harmful ultraviolet rays.

This treatment prevents the plastic from degrading, discoloring, or becoming brittle over time due to prolonged sun exposure.

Temperature Resistance

Plastic sheet waterproof materials are designed to withstand extreme temperature variations without compromising their structural integrity.

Whether exposed to freezing cold or scorching heat, these sheets maintain their flexibility and strength, ensuring reliable protection in diverse climates.

This temperature resistance makes them suitable for both indoor and outdoor applications, including roofing, insulation, and protective coverings in environments subject to harsh weather conditions.

Applications Of Waterproof Plastic Sheets

Waterproof plastic sheets are highly versatile and find applications across numerous industries and settings.

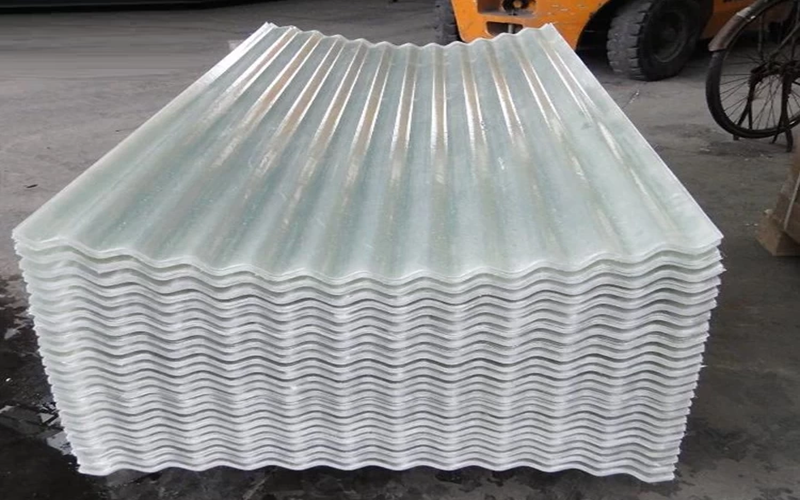

Roofing

Waterproof plastic sheets are extensively used in roofing applications to provide a reliable barrier against water infiltration.

These sheets act as vapor barriers and moisture barriers, preventing rainwater, snow, and humidity from damaging the underlying building structures.

Their durability and resistance to tearing and UV exposure ensure long-lasting protection, reducing maintenance costs and extending the lifespan of roofs.

Agriculture

In agriculture, waterproof plastic sheets are essential for protecting crops and optimizing growth conditions.

They are commonly used as greenhouse covers to create controlled environments that retain heat and moisture, promoting healthy plant development.

Additionally, these sheets serve as pond liners, preventing water seepage and maintaining water levels for irrigation and aquaculture. Soil protection is another critical application, where plastic sheets help retain soil moisture, reduce erosion, and prevent weed growth.

Packaging

Waterproof plastic sheets play a crucial role in packaging by providing a reliable barrier against moisture, ensuring that products remain dry and protected during storage and transportation.

These sheets are used to create durable, water-resistant packaging materials that safeguard goods from water damage, humidity, and other environmental factors.

Their resistance to tears and punctures helps maintain the integrity of the packaging, reducing the risk of product spoilage or contamination.

Industrial Use

Waterproof plastic sheets are widely utilized in industrial settings to protect machinery, equipment, and workspaces from moisture, chemicals, and environmental hazards.

These sheets serve as effective protective liners and containment barriers, preventing corrosion, rust, and damage caused by exposure to water and harsh substances.

Their durability and resistance to tears and chemicals make them ideal for covering heavy machinery, storage areas, and production lines.

How To Choose The Right Plastic Sheet Waterproof?

Choosing the right plastic sheet waterproof material depends on several important factors to ensure optimal performance and longevity.

First, consider the specific application and environment where the sheet will be used—whether indoors or outdoors—as this influences the required UV protection and temperature resistance.

Next, evaluate the thickness and durability needed based on potential exposure to wear, tear, and chemicals.

It is also essential to check the material type, such as HDPE, PVC, or polycarbonate, each offering unique benefits in terms of flexibility, strength, and resistance.

Additionally, consider the sheet’s transparency or opacity based on your project needs.

Finally, take note of stock levels and transit times from regional warehouses to ensure timely delivery and availability.

By carefully assessing these criteria, you can select a plastic sheet waterproof product that not only protects effectively but also delivers long-term value and cost savings.

Conclusion

In summary, plastic sheet waterproof materials offer a versatile and reliable solution for a wide range of applications, from construction and agriculture to packaging and industrial use.

Their exceptional water resistance, durability, and UV protection make them ideal for both indoor and outdoor environments.

Because it can sometimes be difficult to sort through the many options available, using a detailed product list with clear ratings and specifications can simplify your decision-making process.

Look for products that include clear arrows or indicators on packaging or online listings to help identify key features quickly.

When ordering, it is important to check stock levels and transit times displayed on the map, as transit days may vary depending on regional warehouses.

Understanding the estimated transit day and the rate of delivery helps you plan your project timeline effectively. Many suppliers offer free shipping options, which can help reduce overall costs.