Thermoforming plastic sheets are widely used for their ability to be easily shaped into a variety of products.

This article explains what thermoforming plastic sheets are, the types of plastics used, and their applications across different industries.

It also highlights the innovative uses of thermoforming plastic sheets in packaging, prototyping, and design, emphasizing their cost effectiveness and versatility compared to other manufacturing methods such as injection molding.

What Are Thermoforming Plastic Sheets?

Thermoforming plastic sheets are specially designed thermoplastic materials that become pliable when heated, allowing them to be molded into various shapes and sizes with high precision.

The versatility of these sheets makes them ideal for applications ranging from food packaging and window frames to industrial components, toys, and consumer goods.

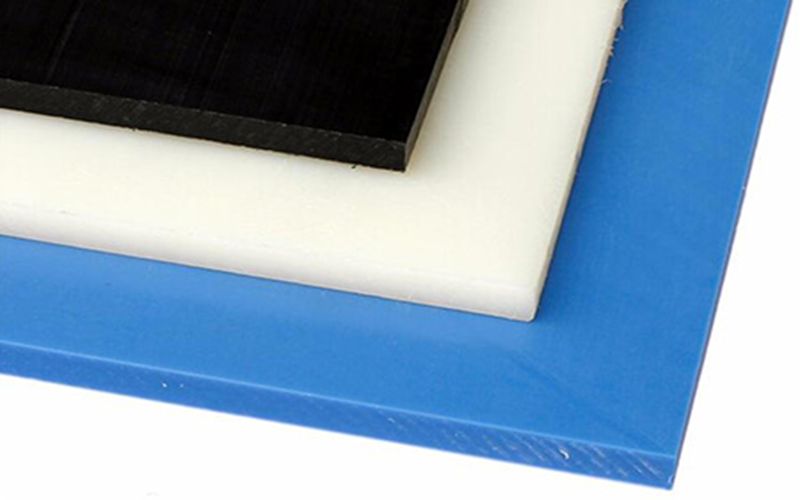

Moreover, thermoforming plastic sheets can be produced in both thin gauge and heavy gauge thicknesses, allowing manufacturers to select the appropriate sheet type based on the required strength, detail, and application of the final product.

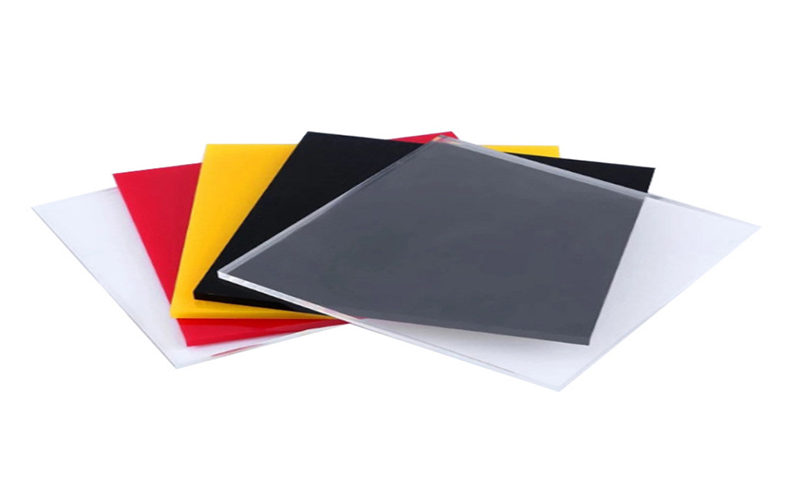

Their smooth surface finish and ability to pull into complex shapes without cracking or breaking enhance the quality and aesthetics of the finished parts.

Overall, thermoforming plastic sheets provide a low cost, cost-effective, and efficient solution for producing high-quality plastic parts with consistent dimensions and excellent durability, making them a preferred choice in many manufacturing processes including injection molding alternatives.

Types Of Thermoforming Plastic Sheets

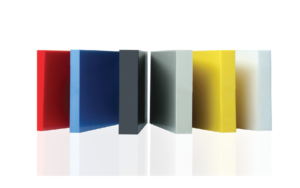

Thermoforming plastic sheets come in a variety of materials, each offering unique properties and advantages suited to different manufacturing needs and applications.

Polyethylene Terephthalate (PETG) Sheet

Polyethylene Terephthalate Glycol modified is a transparent and highly durable thermoplastic commonly used in the thermoforming plastic sheet process.

Known for its excellent clarity and impact resistance, PETG is favored for applications requiring a smooth, transparent surface and strong structural integrity.

This material is especially popular in manufacturing food packaging, medical trays, and protective covers where both safety and visibility are critical.

High Impact Polystyrene (HIPS) Sheet

High Impact Polystyrene is a widely used thermoplastic in the plastic thermoforming industry due to its excellent balance of low cost, durability, and ease of fabrication.

Additionally, HIPS is favored in prototyping and low-volume manufacturing because it is easy to thermoform, cools quickly, and resists cracking during the process.

Combining these properties, HIPS provides manufacturers with a cost-effective and versatile option for producing durable plastic components with a high level of detail and consistent quality in plastic thermoforming processes.

Acrylonitrile Styrene Butadiene (ABS) Sheet

Acrylonitrile Styrene Butadiene is a highly durable and rigid thermoplastic widely used in the thermoforming plastic sheet industry.

ABS combines strength, impact resistance, and flexibility, making it well suited for manufacturing plastic parts that require both toughness and precision.

This material is favored in applications ranging from automotive components and electronic housings to consumer goods and toys. Its excellent surface finish allows for smooth, glossy products that can be easily painted or decorated.

Polyvinyl Chloride (PVC) Sheet

Polyvinyl Chloride is a highly versatile thermoplastic widely used in the thermoforming plastic sheet industry due to its excellent durability, chemical resistance, and adaptability.

PVC sheets can be manufactured in both rigid and flexible forms, making them suitable for a broad range of applications including window frames, pipes, signage, and protective covers.

The material’s smooth surface finish and ability to maintain strength under various environmental conditions enhance its appeal for industrial and consumer products alike.

Thermoforming Plastic Sheet Processes

Thermoforming encompasses various methods to shape heated plastic sheets, including vacuum forming and pressure forming.

Vacuum Forming

Vacuum forming is one of the most widely used thermoforming plastic sheet processes due to its simplicity and cost effectiveness.

In this process, a plastic sheet is heated until it becomes pliable, then stretched over a mold.

A vacuum is applied to suck the air out from between the sheet and the mold, causing the plastic to conform tightly to the mold’s shape.

Vacuum forming offers advantages like fast cycle times, low tooling costs, and the ability to use a variety of plastic materials including acrylic, polycarbonate, and PVC.

Pressure Forming

Pressure forming is an advanced thermoforming plastic sheet process that builds upon vacuum forming by applying additional air pressure to the heated plastic sheet.

After the sheet is softened by heat and positioned over the mold, a vacuum removes the air between the sheet and the mold, and then positive pressure is applied from above to push the plastic firmly against the mold surface.

Pressure forming is especially suited for creating complex shapes and parts with intricate features, such as automotive interior panels, appliance housings, and high-quality packaging.

Advantages Of Thermoforming Plastic Sheets

Thermoforming plastic sheets offer several significant advantages that make them a preferred choice for manufacturers across various industries.

Cost Effectiveness

One of the key advantages of thermoforming plastic sheets is their cost effectiveness.

Compared to other manufacturing processes like injection molding, thermoforming requires lower initial tooling costs and shorter setup times, making it ideal for both prototyping and low to medium volume production runs.

The ability to use a wide variety of plastic materials, including both thin gauge and heavy gauge sheets, allows manufacturers to optimize material costs based on the specific application.

Material Versatility

One of the standout benefits of thermoforming plastic sheets is their exceptional material versatility.

This includes commonly used plastics such as polyvinyl chloride, polyethylene terephthalate, acrylonitrile styrene butadiene, and high impact polystyrene.

The availability of both thin gauge thermoforming sheets for lightweight packaging and heavy gauge sheets for durable industrial components allows for flexibility in product design and performance.

Efficiency

Thermoforming plastic sheets is a highly efficient manufacturing process that offers rapid production cycles and minimal material waste.

The heating and forming stages are quick, allowing manufacturers to produce large volumes of plastic parts in a shorter time compared to other methods such as injection molding.

Additionally, the ability to use both thin gauge and heavy gauge sheets means that manufacturers can optimize material usage based on the product’s requirements, further enhancing cost savings and reducing environmental impact.

Design Flexibility

One of the significant advantages of thermoforming plastic sheets is the exceptional design flexibility it offers.

Manufacturers can create a wide variety of shapes, sizes, and textures with relative ease, accommodating both simple and complex product designs.

This flexibility makes it possible to produce intricate details, undercuts, and varying thicknesses within a single part, which is particularly beneficial for industries requiring tailored solutions such as automotive, medical devices, and consumer electronics.

Applications Of Thermoformed Plastic Sheets

Thermoforming can produce items ranging from packaging to durable parts for vehicles and medical devices. This highly adaptable process is useful for manufacturing a diverse range of products across different industries.

Thermoformed sheets are extensively used in various applications, including food packaging, consumer goods, and industrial components.

Food Packaging

Thermoforming plastic sheets are extensively used in the food packaging industry due to their excellent durability, clarity, and safety.

These sheets can be easily molded into various shapes such as trays, clamshells, and containers that securely protect food products while maintaining freshness.

Materials like polyethylene terephthalate and polyvinyl chloride are commonly chosen for food packaging because they offer strong barrier properties against moisture and oxygen, ensuring longer shelf life.

Industrial Components

Thermoforming plastic sheets are extensively utilized in the production of industrial components due to their durability, versatility, and cost-effectiveness.

These components often require precise shapes and consistent quality, which thermoforming processes like vacuum forming and pressure forming can reliably deliver.

Common industrial applications include manufacturing protective covers, panels, trays, and housings used in machinery and equipment.

Consumer Goods

Thermoforming plastic sheets are widely used in the consumer goods industry due to their versatility, durability, and cost-effectiveness.

This manufacturing process allows for the creation of a broad range of everyday products such as toys, household items, appliance housings, and decorative components.

The ability to form complex shapes with smooth surfaces and consistent dimensions makes thermoforming an ideal choice for producing attractive and functional consumer goods.

Summary

In summary, thermoforming plastic sheets is a versatile and efficient manufacturing process that plays a critical role in various industries.

From food packaging to industrial components and consumer goods, the applications of thermoformed plastic sheets are vast and varied.

The advantages of thermoforming, including cost-effectiveness, speed, and material versatility, make it an indispensable process in modern manufacturing.

Examples of thermoformed products include food trays, window frames, toys, and protective covers, demonstrating the process’s flexibility.

Additionally, the ability to cart add customized molds and tools, including those made from metal plates, into production workflows streamlines manufacturing and reduces lead times.

By understanding the different types of thermoplastics, the forces involved, and the processes used, manufacturers can make informed decisions that enhance their production capabilities and product quality.