Plastic sheet extrusion is a fundamental manufacturing process that transforms raw plastic pellets into continuous, uniform sheets used across a wide range of industries.

From packaging and automotive to medical and construction applications, this versatile technique enables the production of high-quality plastic sheets with precise thickness, surface texture, and specific properties.

In this comprehensive guide, we will explore the plastic sheet extrusion process, key materials involved, advantages, challenges, and the latest innovations shaping the future of this essential technology.

What Is Plastic Sheet Extrusion?

Plastic sheet extrusion is a continuous and highly efficient manufacturing process where plastic granules or pellets are melted and extruded through a precisely engineered flat die to form thin, uniform plastic sheets.

The molten plastic is rapidly cooled by cooling rolls and vacuum-assisted systems to solidify the sheet while maintaining exact sheet thickness, consistent surface texture, and dimensional stability.

The extrusion process supports the mixing of additives and co-extrusion of multiple layers, allowing manufacturers to produce sheets with enhanced functionality tailored to different applications.

Plastic sheet extrusion serves a wide range of industries—including packaging, automotive, medical, and construction—offering cost-effective production, consistent product quality, and the ability to form sheets into complex shapes using molds and forming technologies.

Process Of Plastic Sheet Extrusion

The process of plastic sheet extrusion involves several key components working together to transform raw plastic pellets into high-quality plastic sheets.

Initially, plastic pellets are fed into the extruder, where a rotating screw generates mechanical energy and heat to melt the plastic uniformly.

Following cooling, the solidified plastic sheet is pulled through a series of rollers that control the sheet’s tension and thickness before being cut to the desired size by a cutting and stacking system.

Furthermore, after extrusion, the plastic sheets can undergo further processing such as thermoforming, where the sheets are heated and formed into a new shape using molds, enabling the creation of complex parts with precise dimensions.

This forming cycle times are optimized by controlling sheet thickness and material properties, ensuring efficiency and high-quality finished products.

The integration of individual components such as extruders, dies, cooling rolls, and pull rollers within extrusion lines ensures smooth operation and consistent output.

Types Of Materials Used In Plastic Sheet Extrusion Lines

Selecting appropriate materials is essential for achieving desired properties and performance in plastic sheet extrusion.

Polyethylene (PE)

Polyethylene is one of the most commonly used polymers in plastic sheet extrusion due to its excellent balance of flexibility, chemical resistance, and cost-effectiveness.

It is widely favored in packaging materials because it provides durable, moisture-resistant sheets that perform well under various environmental conditions.

PE’s versatility allows it to be extruded into sheets of different thicknesses and surface textures, making it suitable for applications ranging from food packaging films to heavy-duty industrial liners.

Polypropylene (PP)

Polypropylene (PP) is a widely used thermoplastic polymer known for its excellent heat resistance, chemical stability, and mechanical strength.

In plastic sheet extrusion, PP is favored for applications requiring durable and lightweight sheets, such as automotive parts, household goods, and industrial components.

The extrusion line for PP sheets typically involves precise temperature control and cooling rolls to maintain consistent sheet thickness and surface quality, ensuring the final product meets stringent industrial standards.

Polystyrene (PS)

Polystyrene is a versatile plastic material widely used in plastic sheet extrusion due to its rigidity, ease of molding, and cost-effectiveness.

During the extrusion process, PS pellets are melted and extruded through a flat die to produce sheets with consistent thickness and smooth surface texture.

These extruded sheets can be further processed or thermoformed into various shapes using molds, making PS an ideal choice for products that demand precise dimensions and good impact resistance.

Polycarbonate (PC)

Polycarbonate is a highly durable and impact-resistant thermoplastic widely used in plastic sheet extrusion.

The extrusion process of PC involves melting the plastic pellets and carefully extruding them through a flat die, followed by rapid cooling using cooling rolls to maintain precise sheet thickness and surface texture.

Additionally, PC sheets can be co-extruded with other materials to add specific properties like UV absorption or improved scratch resistance, expanding their usability across automotive, construction, and electronic industries.

Polyethylene Terephthalate (PET)

Polyethylene Terephthalate is a widely used thermoplastic polymer in plastic sheet extrusion, prized for its excellent strength, chemical resistance, and recyclability.

The extrusion process for PET involves melting plastic pellets and carefully extruding the molten plastic through a flat die, followed by rapid cooling using advanced cooling rolls to maintain consistent sheet thickness and surface texture.

Furthermore, PET’s ability to be recycled efficiently supports sustainable manufacturing practices, aligning with the growing demand for environmentally friendly plastic products.

Polyvinyl Chloride (PVC)

Polyvinyl Chloride is a versatile and widely used plastic material in the plastic sheet extrusion industry due to its excellent durability, chemical resistance, and cost-effectiveness.

The extrusion process for PVC involves melting plastic pellets and extruding the molten plastic through a flat die, followed by rapid cooling using advanced cooling rolls to ensure consistent sheet thickness and surface texture.

Additionally, PVC sheets can be easily thermoformed into complex shapes using molds, enabling the production of customized components with precise dimensions and excellent surface finish.

Advantages Of Plastic Sheet Extrusion

Plastic sheet extrusion offers numerous benefits that make it a preferred manufacturing process across various industries.

Cost Effective

Plastic sheet extrusion is renowned for its cost-effective nature, making it a preferred choice for large-scale manufacturing.

By utilizing advanced extrusion machines equipped with precise temperature controls and optimized cooling rolls, manufacturers can maintain consistent sheet thickness and surface texture, which reduces material scrap and rework.

Additionally, the ability to co-extrude one or more layers in a single pass further enhances cost savings by combining multiple material properties without the need for separate processing steps.

Consistent Product Quality

One of the key advantages of plastic sheet extrusion is its ability to deliver consistent product quality. The process is designed to maintain uniform sheet thickness, precise surface texture, and dimensional stability throughout production.

This consistency is achieved through the careful control of extrusion parameters such as temperature, pressure, and screw rotation speed, as well as the use of advanced cooling rolls and vacuum systems that rapidly solidify the molten plastic.

Consistent product quality reduces material waste and rework, making plastic sheet extrusion a preferred method for producing high-quality plastic sheets across multiple industries.

Rapid Cooling And Forming

Rapid cooling and forming are critical stages in the plastic sheet extrusion process that directly impact the quality and performance of the final product.

This rapid cooling solidifies the plastic sheet while preserving precise sheet thickness and consistent surface texture, preventing defects such as warping or internal stresses.

In some applications, rubber molds are employed to provide flexibility and intricate detail during forming.

Challenges In Plastic Sheet Extrusion

Plastic sheet extrusion, while highly efficient, presents several challenges that manufacturers must address to ensure product quality and process reliability.

Cooling Control

Effective cooling control is vital in the plastic sheet extrusion process to ensure that molten plastic solidifies uniformly and maintains the desired sheet thickness and surface texture.

Precise regulation of cooling rolls and vacuum systems helps prevent common defects such as warping, shrinkage, and internal stresses that can compromise the quality and dimensional stability of the final product.

Die Clogging

Die clogging is a common challenge in plastic sheet extrusion that occurs when contaminants, degraded materials, or unmelted plastic particles accumulate inside the extrusion die.

This buildup restricts the smooth flow of molten plastic, leading to inconsistent sheet thickness, surface imperfections, and potential defects in the final product. Frequent die clogging can cause production interruptions, increased maintenance costs, and reduced overall efficiency.

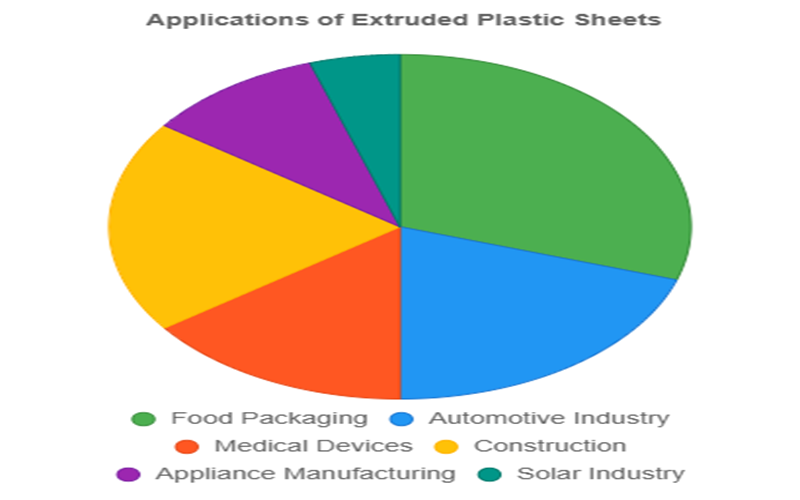

Applications Of Extruded Plastic Sheets

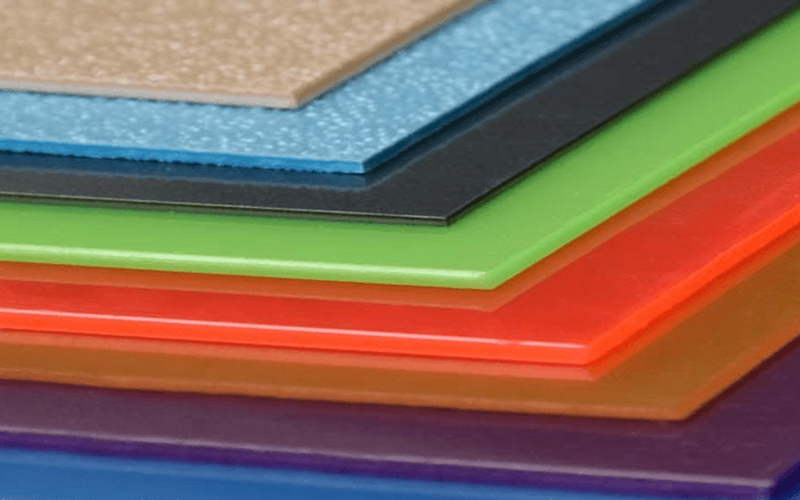

Extruded plastic sheets are widely used across various industries due to their versatility, durability, and customizable properties.

Automotive Industry

The automotive industry heavily relies on plastic sheet extrusion to produce durable, lightweight, and precisely engineered components.

Extruded plastic sheets are used to manufacture essential parts such as weather seals, gaskets, interior trim panels, and protective barriers.

These components require excellent resistance to wear, heat, and chemicals, which plastic sheet extrusion can consistently deliver by controlling sheet thickness and surface texture.

Medical Devices

In the medical device industry, plastic sheet extrusion plays a vital role in producing high-quality, medical-grade sheets that meet stringent hygiene and safety standards.

These extruded sheets are commonly made from materials such as PVC and polyethylene, which offer excellent chemical resistance, biocompatibility, and durability.

The precise control of sheet thickness and surface texture during extrusion ensures that the final products, including tubing, catheters, sterile packaging, and surgical trays, are consistent and reliable.

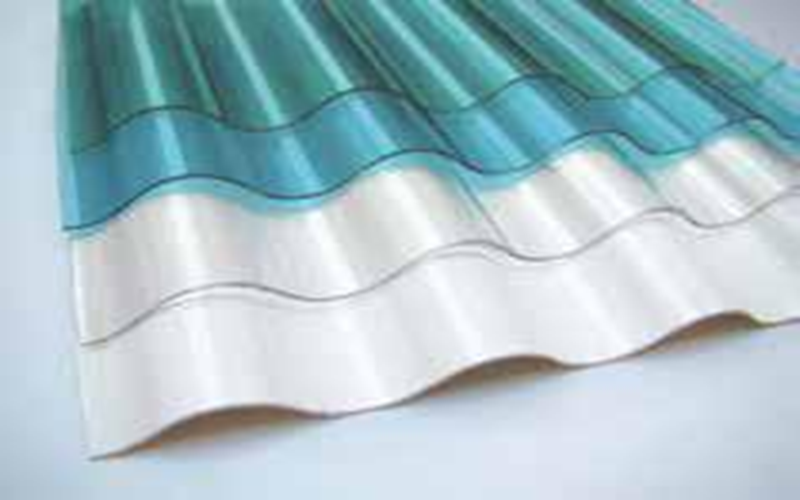

Construction

In the construction industry, extruded plastics sheets play a vital role in enhancing the durability, energy efficiency, and weather resistance of building components.

These sheets are commonly used to manufacture weather-resistant windows, doors, insulation panels, and plastic film.

With their lightweight yet robust nature, extruded plastic sheets contribute to easier installation and long-lasting structural integrity, making them an indispensable material in modern construction projects.

Innovations In Plastic Sheet Extrusion

Plastic sheet extrusion technology continues to evolve rapidly, driven by the need for higher efficiency, improved product quality, and expanded application possibilities.

One of the most impactful innovations is the advancement in co-extrusion techniques, enabling the production of multi-layered sheets with distinct layers that provide enhanced properties such as UV absorption, energy reflection, and improved durability.

This layered approach allows manufacturers to tailor sheets for specific industrial applications while maintaining cost-effectiveness.

Another key innovation is the development of foamed extrusion processes, where gas is injected into molten plastic to create lightweight sheets with superior insulation and impact resistance.

These foamed sheets are particularly valuable in automotive and construction industries, where reducing weight without compromising strength is critical.

Conclusion

The plastic sheet extrusion process is crucial in modern manufacturing, transforming raw plastic materials into versatile, high-quality sheets of varying thickness, including thick sheets for specialized applications.

Understanding this process helps optimize production and ensure consistent quality in the final product.

As the industry advances, exploring new technologies and sustainable practices can further enhance the efficiency and effectiveness of plastic sheet extrusion.

Additionally, the use of mold in post-extrusion forming processes allows manufacturers to shape extruded sheets into complex parts with precise dimensions, expanding the range of possible applications.

In summary, plastic sheet extrusion is a dynamic and evolving field offering numerous benefits and opportunities.