Heat resistant plastic sheets have become essential materials in modern industries, offering a perfect combination of durability, thermal stability, and versatility.

Designed to withstand extreme temperatures without compromising their structural integrity, these advanced plastics provide excellent dimensional stability and resistance that traditional materials like metal and glass often lack.

This article explores the fundamentals of heat resistant plastic sheets, helping you learn about their unique properties, various types, and wide-ranging applications.

What Is Heat Resistant Plastic Sheet?

A heat resistant plastic sheet is a specially engineered material designed to withstand high temperatures without losing its mechanical strength or structural integrity.

Unlike conventional plastics that may melt, deform, or degrade when exposed to heat, heat resistant plastic sheets maintain their stability and performance even under continuous exposure to elevated temperatures.

These sheets are commonly used in industries where thermal resistance is essential, such as automotive, aerospace, electronics, and construction.

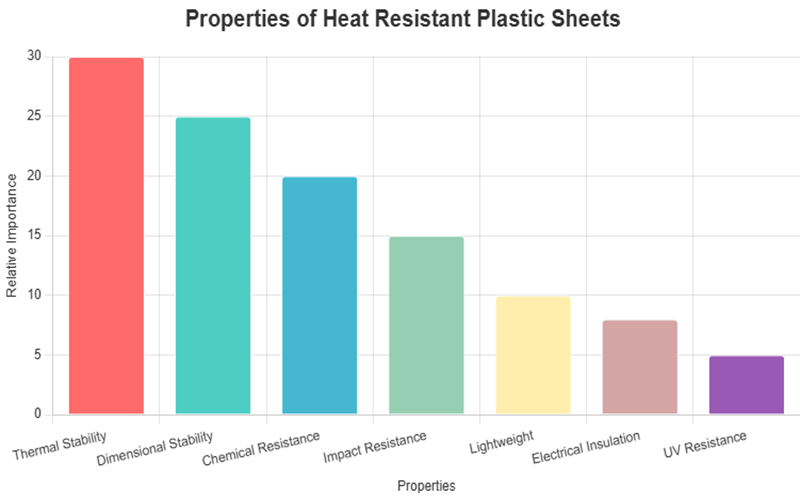

Properties Of Heat Resistant Plastic Sheet

Heat resistant plastic sheets possess several key properties that make them ideal for demanding applications.

Thermal Stability

Thermal stability is a crucial property of heat resistant plastic sheets, allowing them to maintain their shape, strength, and performance even when exposed to high temperatures for extended periods.

This stability means these materials do not easily melt, warp, or degrade under thermal stress, making them ideal for applications where consistent performance in extreme heat is essential.

The ability to resist thermal deformation ensures that these plastic sheets can protect components, maintain structural integrity, and provide reliable insulation in demanding environments such as automotive engines, electrical devices, and industrial machinery.

Impact Resistance

Impact resistance is a vital feature of heat resistant plastic sheets, especially in applications where durability and safety are paramount. Materials like polycarbonate sheets are known for their exceptional ability to absorb and withstand sudden shocks or impacts without cracking or breaking.

This makes them an ideal choice for safety glazing, protective barriers, and structural applications where both heat resistance and mechanical strength are essential.

Electrical Insulation

Heat resistant plastic sheets offer excellent electrical insulation properties, making them indispensable in the electronics and electrical industries.

These materials are designed to resist electrical current flow, preventing short circuits and enhancing the safety and reliability of electrical components.

Their superior dielectric strength ensures stable performance even under high temperatures, where conventional plastics might fail. This makes heat resistant plastic sheets ideal for use in circuit boards, insulators, connectors, and other critical electronic parts.

UV Resistance

Heat resistant plastic sheets often feature enhanced UV resistance, making them ideal for outdoor applications where prolonged exposure to sunlight can cause fading, brittleness, or degradation.

This UV resistance is typically achieved through the incorporation of stabilizers or protective coatings that shield the material from harmful ultraviolet rays.

As a result, these plastics maintain their color, clarity, and mechanical properties even after extended periods in harsh sunlight.

Types Of Heat Resistant Plastic Sheets

Heat-resistant plastic sheets come in various forms, each tailored to specific needs and applications. They can be broadly categorized into thermosets, which harden permanently, and thermoplastics, which can be reshaped when heated.

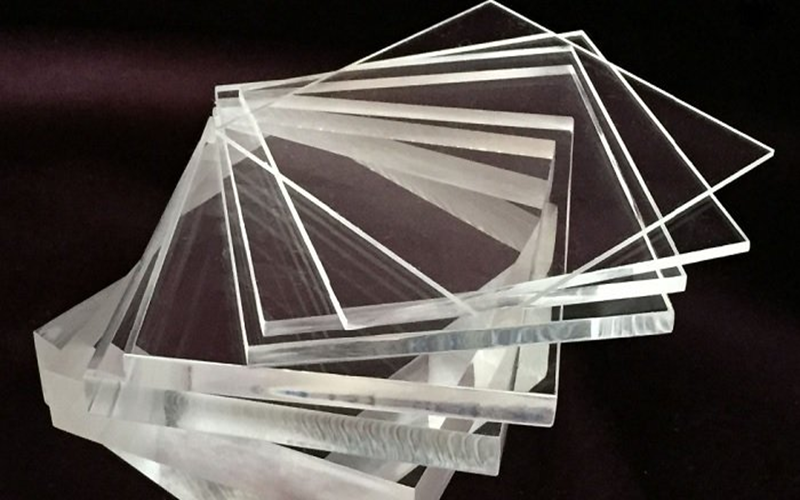

Acrylic Sheet

Acrylic sheets are a popular choice among heat resistant plastic sheets due to their excellent clarity, lightweight nature, and good thermal resistance.

While not as heat resistant as polycarbonate or other high-performance plastics, acrylic provides sufficient resistance for many applications where moderate heat exposure occurs.

Their cost effectiveness combined with reasonable heat resistance makes acrylic sheets an ideal option for projects requiring a balance between performance and budget.

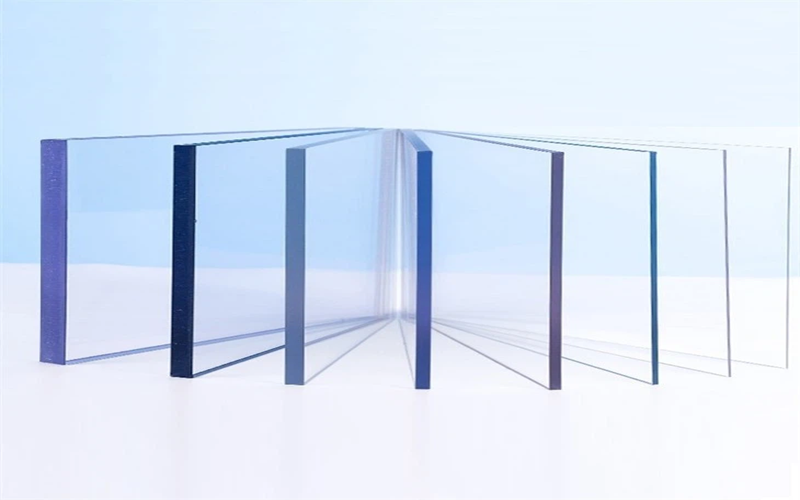

Polycarbonate Sheet

Polycarbonate sheets are a highly versatile and heat resistant plastic sheet option widely used across various industries due to their exceptional properties.

Their excellent dimensional stability ensures that they maintain shape and strength even under prolonged exposure to high temperatures, outperforming many traditional materials like glass and metal.

Additionally, polycarbonate sheets provide excellent light transmission due to their translucent nature, allowing natural light while offering UV resistance to protect against sun damage.

With ease of fabrication, including cutting, drilling, and thermoforming, polycarbonate sheets allow for customized solutions tailored to specific project requirements, making them an ideal material for those looking to find a reliable, heat resistant plastic sheet that combines performance and versatility.

Polyetherimides Sheet

Polyetherimide (PEI) sheets are a top-tier heat resistant plastic sheet option, renowned for their excellent dimensional stability and outstanding thermal resistance.

Capable of withstanding continuous use temperatures up to 217°C (423°F), PEI sheets maintain their mechanical strength and structural integrity even under prolonged exposure to high temperatures.

This makes them an ideal choice for applications demanding both heat resistance and durability.

Polyetheretherketone Sheet

Polyetheretherketone (PEEK) is a high-performance heat resistant plastic sheet renowned for its exceptional strength, chemical resistance, and ability to withstand continuous high temperatures up to 310°C.

This advanced polymer offers excellent dimensional stability and maintains its mechanical properties even under harsh thermal and mechanical stress, making it an ideal choice for demanding structural applications.

Applications Of Heat Resistant Plastic Sheets

Heat resistant plastic sheets are widely used across a variety of industries due to their unique ability to withstand high temperatures while maintaining structural integrity.

Automotive

In the automotive industry, heat resistant plastic sheets play a crucial role in enhancing vehicle performance and safety.

These materials are used in various components such as engine covers, air intake manifolds, and interior panels that require high thermal stability and impact resistance.

By replacing traditional metal parts with heat resistant plastics, manufacturers can significantly reduce vehicle weight, leading to improved fuel efficiency and lower emissions.

Additionally, these advanced plastic sheets contribute to more efficient product transportation by reducing overall vehicle weight, which helps lower transportation costs and environmental impact throughout the supply chain.

Electronics

Heat resistant plastic sheets are indispensable in the electronics industry due to their excellent electrical insulation and thermal stability.

These materials are designed to withstand high temperatures without losing their mechanical strength or compromising safety, making them ideal for use in circuit boards, connectors, and insulating components.

Their ability to protect sensitive electronic parts from heat damage ensures reliable performance and longevity of devices.

Additionally, heat resistant plastic sheets contribute to enhanced security by preventing electrical short circuits and reducing fire hazards, which is essential in high-temperature electronic environments.

Construction

In the construction industry, heat resistant plastic sheets are increasingly favored for their combination of durability, lightweight nature, and excellent thermal resistance.

These sheets serve as a virtually unbreakable alternative to traditional glass, providing superior safety glazing solutions that protect buildings from impact and extreme weather conditions.

Additionally, the ease of fabrication and installation allows architects and builders to select customized thicknesses and colors, optimizing both aesthetic appeal and functional performance.

By choosing heat resistant plastic sheets, construction projects not only benefit from improved security and energy efficiency but also reduce overall structural weight, contributing to more sustainable and cost-effective building designs.

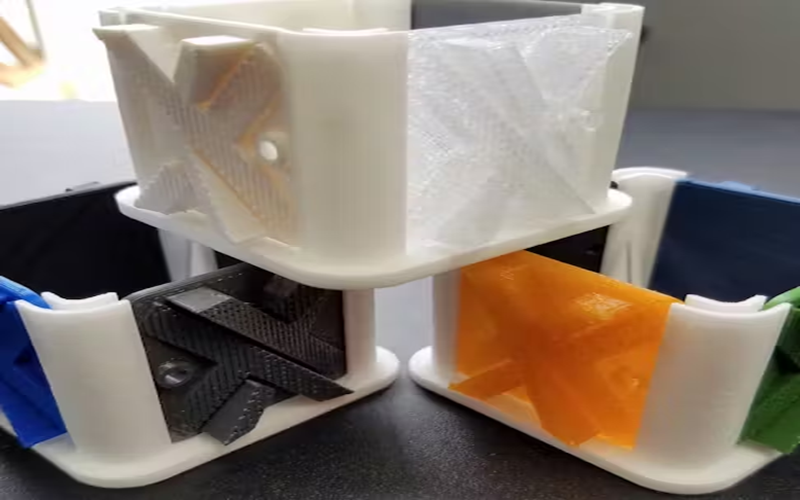

Aerospace

In the aerospace industry, the combination of lightweight and heat resistant plastic sheets is essential for optimizing performance and safety.

These materials are used in structural components, interior panels, and insulation systems where high thermal resistance and excellent dimensional stability are critical.

Heat resistant plastic sheets help reduce overall aircraft weight, improving fuel efficiency and reducing emissions, while maintaining durability under extreme temperature fluctuations encountered during flight.

Advantages Of Heat Resistant Plastic Sheet

Heat resistant plastic sheets offer several significant advantages that make them a preferred choice in many industries.

Virtually Unbreakable

One of the standout features of heat resistant plastic sheets is their virtually unbreakable nature. Unlike traditional glass or metal, these plastic sheets offer exceptional impact resistance, making them ideal for applications where safety and durability are paramount.

This toughness ensures that the material can withstand harsh conditions, accidental impacts, and mechanical stress without cracking or shattering.

As a result, they provide enhanced protection in safety glazing, protective barriers, and structural applications.

Versatility

Heat resistant plastic sheets are remarkably versatile materials that can be tailored to suit a wide range of applications across multiple industries.

Available in various thicknesses, colors, and formulations, these sheets offer customization options that allow users to select the ideal product to meet specific project requirements.

Whether you need a translucent sheet for safety glazing, a thick and durable panel for structural applications, or a lightweight component for transportation, heat resistant plastic sheets can be adapted accordingly.

Cost Effective

Heat resistant plastic sheets offer a cost-effective solution for many industries by combining durability with low maintenance requirements.

While the initial investment may be higher than traditional materials like glass or metal, their long lifespan and resistance to damage reduce replacement and repair costs over time.

This combination of factors makes heat resistant plastic sheets an ideal choice for projects seeking long-term value without compromising on performance or safety.

Disadvantages Of Heat Resistant Plastic Sheet

While heat resistant plastic sheets offer many advantages, there are some disadvantages to consider.

Higher Initial Cost

One notable disadvantage of heat resistant plastic sheets is their higher initial cost compared to traditional materials such as glass or metal.

Therefore, while the initial price may be higher, the total cost of ownership can be more economical when factoring in these benefits.

Limited Chemical Resistance

While heat resistant plastic sheets excel in maintaining their structural integrity under high temperatures, they do have limitations when it comes to chemical resistance.

Certain aggressive chemicals, solvents, or acids can cause degradation or damage to these materials over time.

Thermal Expansion

Thermal expansion is an important consideration when working with heat resistant plastic sheets. These materials tend to expand and contract more than metals or glass when exposed to temperature changes.

This characteristic means that designers and engineers must account for dimensional changes to prevent warping, buckling, or stress in the final application.

How To Select The Right Heat Resistant Plastic Sheet?

Selecting the appropriate heat resistant plastic sheet for your project is essential to ensure optimal performance and durability.

Start by evaluating the specific temperature range your application will encounter, as different plastics offer varying levels of heat resistance.

Consider the mechanical properties required, such as impact resistance and dimensional stability, to match the demands of your environment.

Additionally, assess factors like UV resistance and electrical insulation if your project involves outdoor exposure or electronic components.

Thickness and color options can also influence the material’s suitability, impacting weight and aesthetic appeal.

Finally, choose a reputable supplier that offers customization and fabrication services to tailor the plastic sheet precisely to your needs, ensuring you receive a high-quality, reliable product designed to protect and perform under high temperatures.

Conclusion

Heat-resistant plastic sheets are revolutionizing various industries with their unique properties and applications.

Their ability to withstand high temperatures, combined with their lightweight and versatile nature, makes them an ideal choice for a wide range of projects.

In applications ranging from automotive and electronics to construction and safety glazing, these materials offer unmatched performance and reliability.

In addition to their thermal and mechanical advantages, these plastic sheets enhance security by providing virtually unbreakable alternatives to traditional materials.

Users unable to find suitable options on other websites can click through comprehensive product pages to select the perfect heat resistant plastic sheet tailored to their needs.

With ongoing advancements in material science, the potential applications and benefits of heat-resistant plastic sheets will continue to grow.

Embracing these innovative materials can lead to more efficient, durable, and cost-effective solutions across various fields.

For manufacturers, engineers, or designers, understanding this information about materials and their capabilities is crucial for staying ahead in today’s competitive landscape.