In today’s world, finding sustainable and eco-friendly materials is more important than ever.

Recycled HDPE sheets offer a durable, versatile, and environmentally responsible solution by transforming plastic waste into valuable products. These sheets are breathing new life into discarded plastics, extending the life of materials and contributing to a healthier, more sustainable environment.

This article will introduce you to the benefits, properties, and wide-ranging applications of recycled HDPE sheets, highlighting their role in promoting a circular economy and reducing plastic pollution.

What Are Recycled HDPE Sheets?

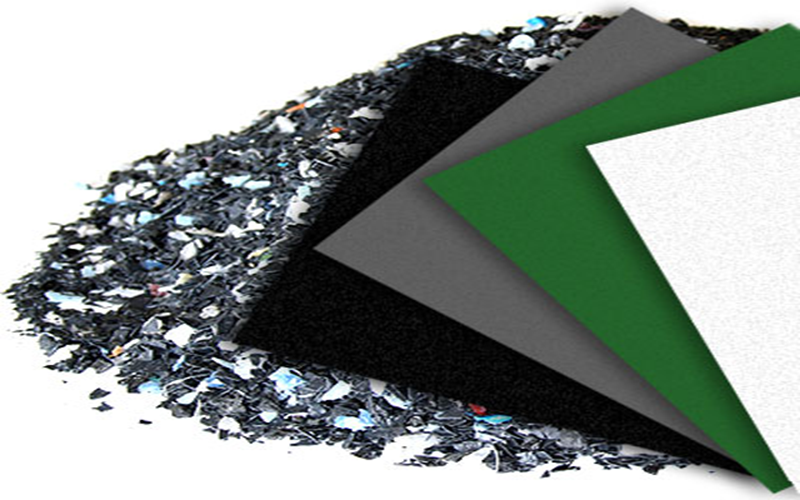

Recycled HDPE sheets are high-density polyethylene plastic sheets made entirely or predominantly from recycled plastic waste.

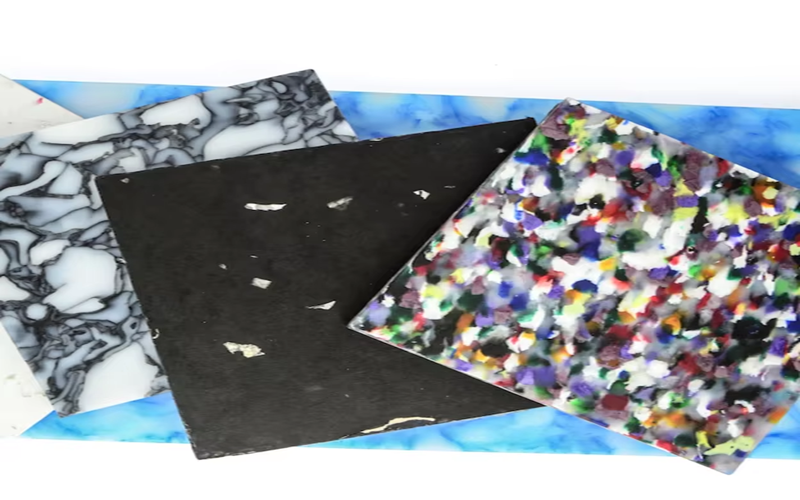

These sheets are produced by collecting post-consumer and post-industrial HDPE plastic materials, such as bottles, containers, and packaging, which are then thoroughly cleaned, processed, and reformed into durable, high-quality sheets.

Unlike virgin HDPE sheets, recycled versions significantly reduce reliance on new plastic production, helping to conserve natural resources, lower carbon emissions, and minimize environmental impact.

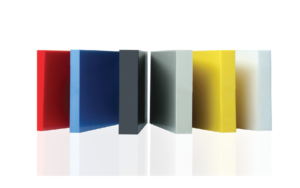

Known for their extreme durability, excellent chemical and mold resistance, and versatility, recycled HDPE sheets are widely used across various industries including construction, marine, furniture, and retail.

Key Properties Of Recycled HDPE Sheets

Recycled HDPE sheets boast an impressive array of properties that make them suitable for various applications.

Their strong impact and abrasion resistance ensure durability in even the most demanding environments. Additionally, the ease of handling and fabrication of recycled HDPE sheets can help save time during installation, making them an efficient choice for projects with tight deadlines.

Mold Resistance

Recycled HDPE sheets exhibit excellent resistance to chemicals and mold, ensuring long-lasting performance and reliability in both industrial and outdoor environments.

This mold resistance contributes to their durability, making them an ideal choice for applications exposed to moisture and harsh conditions.

Stability

Recycled HDPE sheets, especially those with matte finishes, offer exceptional stability and a clean, consistent surface that is ideal for both functional and aesthetic applications.

This stability ensures minimal warping or deformation, even under varying environmental conditions, making these sheets highly reliable for diverse projects.

Lightweight

Despite their extreme durability and robust strength, recycled HDPE sheets remain lightweight.

This characteristic facilitates easier handling, transportation, and installation, significantly reducing labor costs and effort without compromising performance.

Their lightweight nature makes them particularly suitable for applications in furniture fabrication, marine environments, and construction projects where ease of use and material efficiency are critical.

The Recycling Process Of LDPE Sheets

Recycling LDPE (Low-Density Polyethylene) sheets is a fundamental process that transforms plastic waste into valuable recycled HDPE sheets, contributing significantly to sustainability and the circular economy.

The journey begins with the collection of LDPE waste materials such as plastic bags, packaging films, and containers, which are then carefully sorted to eliminate contaminants and ensure the quality of the recycled product.

Following sorting, the LDPE waste undergoes rigorous cleaning to remove dirt, labels, and residues.

The clean plastic is then shredded into small flakes, washed again, and dried to prepare for the extrusion process.

These flakes are melted and formed into new recycled HDPE sheets through extrusion, preserving key properties like extreme durability, chemical resistance, and versatility. This entire process is supported by a robust in-house system—a ‘house’ of advanced infrastructure and technology—that ensures efficient recycling and high-quality production.

This recycling process not only diverts plastic waste from landfills but also reduces the demand for virgin plastic production, lowering carbon emissions and conserving natural resources.

Innovations in recycling technology continue to enhance the quality and efficiency of LDPE sheet recycling, enabling manufacturers to produce sustainable, lightweight, and durable materials suitable for a wide range of industries including construction, marine, retail, and furniture fabrication.

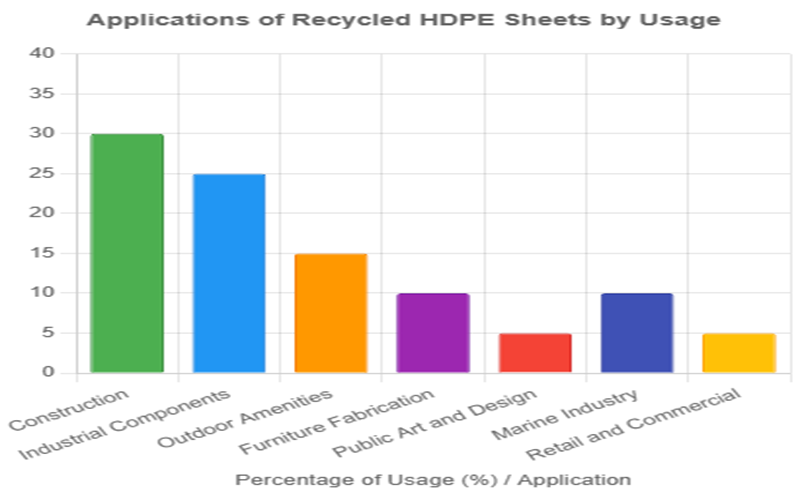

Applications Of Recycled HDPE Sheets

Recycled HDPE sheets have become an essential material across numerous industries due to their outstanding durability, versatility, and eco-friendly nature.

From construction to furniture fabrication and marine applications, these sheets provide sustainable solutions that meet the demanding requirements of modern projects.

Construction

Recycled HDPE sheets are extensively utilized in construction for a variety of applications, including pipes, drainage systems, and other critical infrastructure components.

Their outstanding corrosion resistance, chemical stability, and extreme durability make them ideal for withstanding harsh environmental conditions.

Additionally, their lightweight and versatile nature facilitates easier handling and installation, reducing overall project costs.

By choosing recycled HDPE sheets, construction projects not only benefit from high-performance materials but also contribute to sustainability goals and the advancement of the circular economy.

Furniture Fabrication

Lightweight yet extremely durable, recycled HDPE sheets are perfect for crafting sustainable furniture pieces that combine functionality with eco-friendly design.

Their resistance to moisture, mold, and impact makes them ideal for both indoor and outdoor furniture applications.

Additionally, these sheets can be easily shaped and customized through CNC cutting, allowing designers and manufacturers to create innovative, long-lasting furniture that supports the circular economy and reduces plastic waste.

Marine Industry

Recycled HDPE sheets are highly resistant to moisture and mold, making them an excellent choice for marine applications.

Their extreme durability and chemical resistance ensure long-lasting performance in harsh saltwater environments.

Lightweight and versatile, these sheets are widely used for boat components, dock surfaces, and marine furniture, supporting sustainability by reducing plastic waste in the marine industry.

Environmental Impact Of Recycled HDPE Sheets

The environmental impact of recycled HDPE sheets is profoundly positive, making them a standout choice for anyone committed to sustainability and reducing plastic waste.

By transforming discarded plastics into valuable, durable materials, companies like The Good Plastic Company are actively supporting the circular economy and helping to protect our planet.

Recycled HDPE sheets are manufactured from 100% recycled material, sourced from post-consumer and post-industrial plastic waste.

This eco-friendly process not only diverts plastics from landfills and oceans but also significantly reduces the need for virgin plastic production.

As a result, the use of recycled HDPE sheets helps conserve natural resources and lowers greenhouse gas emissions, making a tangible difference in the fight against plastic pollution.

One of the key advantages of recycled HDPE sheets is their extreme durability and resistance to mold, rot, and swell.

Their versatility extends to furniture design, architectural applications, and innovative fabrication projects, offering designers and architects a sustainable material that meets the highest standards of quality and performance.

The growing demand for eco-friendly materials has led to an increase in official distributors and manufacturers dedicated to providing high-quality recycled HDPE sheets.

These industry leaders not only supply a wide range of options but also educate clients on the benefits of choosing recycled materials for their projects.

By opting for recycled HDPE sheets, businesses and individuals can reduce their environmental footprint and contribute to a more sustainable future.

Future Trends In Recycled HDPE Sheets

The future of recycled HDPE sheets is bright, driven by continuous innovation and growing demand for sustainable materials.

Advances in recycling technology are enabling manufacturers to produce recycled HDPE sheets with even higher purity, enhanced mechanical properties, and improved surface finishes.

These improvements expand the range of applications, making recycled HDPE sheets suitable for more demanding industries such as automotive, aerospace, and high-end furniture design.

Moreover, the integration of smart technologies and additives is paving the way for recycled HDPE sheets with enhanced functionalities, including UV resistance, antimicrobial properties, and increased fire retardancy.

This evolution supports the expanding needs of designers and manufacturers seeking eco-friendly yet high-performance materials.

With increasing global emphasis on circular economy principles, more official distributors and locations are emerging worldwide to provide easy access to high-quality recycled HDPE sheets.

Leading companies like the Good Plastic Company are at the forefront of this movement, offering innovative, certified sustainable materials that meet stringent environmental standards.

How To Source And Use Recycled LDPE Plastic Sheets?

Sourcing high-quality recycled LDPE plastic sheets requires careful consideration to ensure you receive durable, eco-friendly materials that meet your project’s specific needs.

Start by selecting reputable manufacturers known for their commitment to sustainability and quality control. Look for certifications such as ISO 14001 or Environmental Product Declarations (EPDs), which verify the material’s environmental credentials and consistent performance.

Pay attention to detailed product specifications including thickness, density, and surface finish to ensure suitability for your intended application.

When using recycled LDPE plastic sheets, proper handling and fabrication techniques are essential to maintain their integrity and maximize their lifespan.

CNC cutting is highly recommended for precise shaping and sizing, reducing waste and enhancing the quality of finished products.

Additionally, consider the environment where the sheets will be used—factors like exposure to moisture, chemicals, or UV light can influence the choice of grade and finish.

By sourcing from trusted suppliers and applying best practices in fabrication, recycled LDPE sheets can deliver exceptional performance across a wide range of industries including packaging, construction, and product design, all while supporting a circular economy and reducing plastic waste.

Conclusion

Recycled HDPE sheets are an exemplary material that combines durability, versatility, and sustainability. Choosing these sheets allows businesses and consumers to significantly reduce plastic waste and support the circular economy.

The benefits of recycled materials extend beyond environmental impact, providing practical solutions for various applications.

Everyone should consider the advantages of recycled HDPE sheets and integrate them into their projects.

Supporting sustainable practices and innovations benefits the planet and paves the way for a cleaner, greener future. Take action today by choosing recycled materials and contributing to a more sustainable world.

Together, we can make a difference by embracing recycled HDPE sheets and other sustainable materials every day as a team.

Frequently Asked Questions

What Are Recycled HDPE Sheets Made From?

Recycled HDPE sheets are produced from post-consumer or post-industrial plastic waste, effectively repurposing it into high-quality recycled plastic sheets. Companies like the Good Plastic Company specialize in transforming this plastic waste into durable, eco-friendly materials.

What Are The Key Properties Of Recycled HDPE Sheets?

Recycled HDPE sheets are recognized for their robust impact and abrasion resistance, as well as their stability and chemical resistance, which make them highly versatile for numerous applications.

How Is Plastic Waste Recycled Into Recycled Plastic HDPE Sheets?

Plastic waste, including LDPE and other types, is collected, cleaned, and sorted, then shredded into flakes that are melted and extruded into new recycled plastic HDPE sheets. This process effectively transforms plastic waste into reusable, sustainable materials.

What Are Some Common Applications Of Recycled HDPE Sheets?

Recycled HDPE sheets are commonly utilized in construction, industrial components, outdoor amenities, and furniture. This versatility makes them an excellent choice for various innovative design projects focused on sustainability.

What Are The Key Features And Applications Of Recycled HDPE Sheets Produced By The Good Plastic Company?

The Good Plastic Company’s Polygood recycled HDPE sheets are 100% recycled, durable, lightweight, and waterproof, used in architecture, retail, hospitality, and public sector projects