HDPE plastic sheet, or high density polyethylene, offers incredible strength, durability, and versatility, making it ideal for a multitude of applications across various industries.

From household items like cutting boards and storage bins to industrial uses such as chemical tank linings and livestock containment, HDPE’s adaptability and resilience are unmatched.

This article will delve into what HDPE plastic sheets are, their key properties, and the most common applications across various industries.

What Is High Density Polyethylene (HDPE) Plastic Sheet?

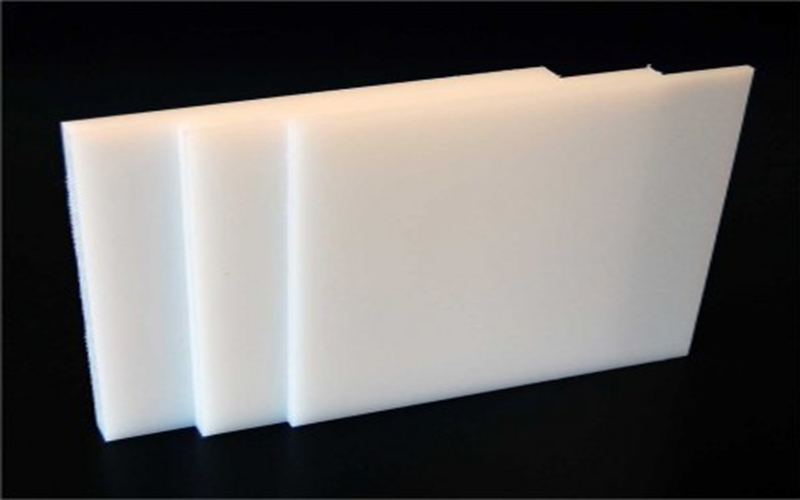

HDPE, or high density polyethylene plastic, is a versatile thermoplastic polymer derived from petroleum, specifically ethylene.

Known for its high strength-to-density ratio, high density polyethylene sheets are both lightweight and exceptionally durable, making them an ideal material for many applications across industries.

This robust nature enables HDPE to withstand significant impact, stress, and harsh environmental conditions, which is essential in numerous industrial, commercial, and household settings.

There are several types of HDPE sheets available, each engineered to meet specific requirements, including smooth, textured, matte, and Color Core finishes.

HDPE plastic sheets are incredibly versatile, used in industrial applications like chemical tank linings, marine-grade components, and livestock containment.

They are also common in everyday household items such as cutting boards, storage bins, and outdoor furniture, demonstrating their adaptability and widespread success.

Types Of High Density Polyethylene Sheets

HDPE plastic sheets come in a variety of finishes, sizes, thicknesses, colors, and quantities to suit different applications and project needs.

These sheets can be easily cut to size, welded, and shaped, with smooth or textured surfaces available to provide the right balance of durability and functionality.

Smooth HDPE Sheet

Smooth HDPE sheets are commonly utilized in educational settings and for machined parts, offering excellent impact resistance and durability.

They are also widely used in industrial contexts, such as livestock containment and chemical tank linings, due to their superior chemical resistance and moisture resistance.

The smooth surface of these sheets makes them easy to clean and maintain, which is essential in environments where hygiene is a priority.

Additionally, smooth HDPE sheets are FDA-approved for food contact, making them perfect for cutting boards and other food preparation surfaces. Their low coefficient of friction and resistance to mold and rot further enhance their suitability for a variety of applications.

Color Core HDPE Sheet

Color Core HDPE sheets are another popular option, featuring solid colors throughout their entire thickness.

This design makes scratches and wear less visible, significantly enhancing the sheet’s longevity and aesthetic appeal.

Additionally, Color Core HDPE sheets maintain all the durability, impact resistance, and chemical resistance properties of standard HDPE, making them a reliable choice for both functional and visual applications.

Textured And Matte HDPE Sheet

Textured and matte HDPE sheets each serve distinct and valuable purposes in various applications.

Textured HDPE sheets provide a non-slip surface, making them ideal for commercial kitchens, food preparation areas, and other environments where slip resistance is essential for safety.

The textured surface also helps reduce wear on cutting tools, extending their lifespan.

Matte HDPE sheets, meanwhile, offer reduced glare and a more subdued appearance, making them suitable for settings with bright lighting or where visual comfort is important.

Both textured and matte HDPE sheets maintain the material’s inherent durability, impact resistance, and chemical resistance, ensuring they perform reliably in demanding conditions.

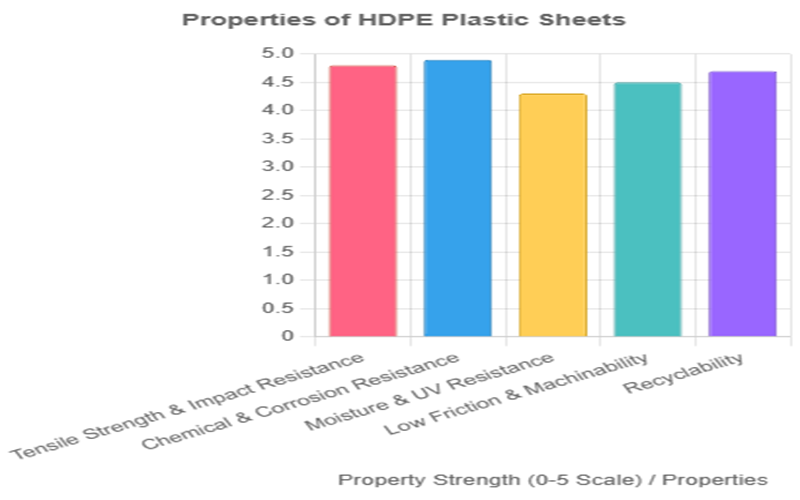

Properties Of HDPE Plastic Sheet

High-Density Polyethylene (HDPE) plastic sheets are renowned for their robust and versatile properties, making them a preferred material in numerous industries.

High Tensile Strength

HDPE plastic sheets exhibit exceptional tensile strength and toughness, allowing them to withstand significant mechanical stress and impacts without cracking, breaking, or deforming.

This durability makes them ideal for demanding applications such as industrial containers, playground equipment, and structural components where long-lasting performance is essential.

Additionally, their resistance to wear and tear ensures that HDPE sheets maintain their integrity even under heavy use, contributing to the material’s reputation as a reliable and impact resistant choice for many projects.

Chemical And Corrosion Resistance

The non-reactive nature of HDPE ensures excellent resistance to a wide range of chemicals, acids, and solvents, as well as corrosion from environmental factors.

This outstanding chemical and corrosion resistance makes HDPE sheets ideal for demanding applications such as chemical storage tanks, piping systems, and industrial containers where exposure to harsh substances is common.

Additionally, HDPE’s durability against corrosive environments contributes to its long service life and reliability in both indoor and outdoor settings.

Low Coefficient Of Friction

The smooth surface of HDPE sheets results in a low coefficient of friction, making them ideal for applications requiring minimal surface drag, such as conveyor systems and sliding components.

Additionally, HDPE is easily machined, cut, or molded, enabling precise fabrication for custom parts. Its ability to hold screws securely without cracking or splitting further enhances its versatility in various projects.

The clean, smooth sides and edges of HDPE sheets also contribute to their ease of handling and installation, ensuring a professional finish in both industrial and DIY applications.

Common Applications For HDPE Sheet

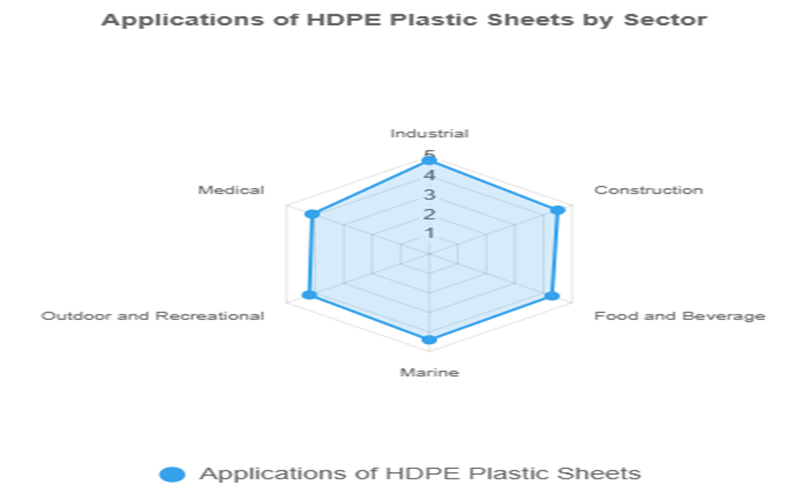

High-Density Polyethylene (HDPE) plastic sheets are widely utilized across diverse industries due to their durability, chemical resistance, and versatility.

Industrial

HDPE sheets are ideal for industrial applications such as chemical storage tanks, pipes, and liners for ponds or lagoons.

Their excellent chemical and corrosion resistance ensures safe containment of hazardous materials and durability in harsh environmental conditions.

Additionally, HDPE’s impact resistance and lightweight nature make it a preferred choice for demanding industrial projects.

These sheets are readily available in various sizes and thicknesses, allowing for customization to fit specific industrial needs.

Many manufacturers proudly stock HDPE plastic sheets in the USA, offering competitive prices and fast shipping options to support timely project completion.

Construction

In construction, HDPE plastic sheets are widely used for roofing, wall panels, and corrosion-resistant piping, providing lightweight yet highly durable solutions that effectively resist moisture, chemicals, and environmental degradation.

These properties ensure long-term structural integrity and reduce maintenance costs. Additionally, HDPE sheets are easy to cut and install, making them a practical choice for contractors and builders seeking reliable, impact-resistant materials that stand up to harsh weather conditions and heavy use.

Food And Beverage

HDPE sheets are FDA-approved for direct food contact, making them an excellent choice for cutting boards, food storage containers, and packaging materials.

Their non-porous, easy-to-clean surfaces ensure superior hygiene by resisting mold, bacteria, and cross-contamination.

Additionally, HDPE’s durability and chemical resistance make it ideal for repeated sanitation processes common in food and beverage industries.

These qualities contribute to HDPE sheets being a trusted material in commercial kitchens and food processing facilities, ensuring safety and compliance with health standards.

Marine

HDPE sheets are widely employed in marine applications, including boat components, dock fenders, antiskid surfaces, and even custom marine signs.

Their exceptional moisture resistance, durability, and impact resistance make them ideal for withstanding harsh saltwater environments.

Additionally, HDPE’s low coefficient of friction and resistance to mold and rot enhance safety and longevity in marine settings, ensuring reliable performance over time.

Outdoor And Recreational

HDPE sheets are commonly used in playground equipment, outdoor furniture, and signage, offering UV-resistant (with additives) and impact-resistant solutions that endure prolonged outdoor exposure while maintaining their aesthetic appeal.

Many users review HDPE sheets positively for their durability and ability to withstand harsh weather conditions, making them a reliable choice for outdoor and recreational applications.

Medical

In the medical field, HDPE sheets are extensively utilized for orthotics, prosthetics, and antimicrobial surfaces, providing lightweight, durable, and hygienic materials that meet stringent safety and performance standards.

Their excellent chemical resistance and ease of sanitation make them ideal for medical environments where cleanliness is paramount.

Additionally, HDPE’s impact resistance and moisture resistance contribute to long-lasting medical devices and equipment, ensuring reliability and patient safety.

Hospitals and healthcare providers often choose HDPE sheets because they are FDA-approved and can be easily cleaned and sanitized to prevent contamination and infection.

HDPE Plastic Sheet vs PVC Plastic Sheet

When comparing HDPE with PVC, the key difference between these materials becomes clear, making HDPE a preferred choice in many applications.

High-Density Polyethylene (HDPE) and Polyvinyl Chloride (PVC) plastic sheets are both versatile thermoplastics widely used across industries, yet they differ significantly in their properties, performance, and environmental impact.

HDPE sheets offer superior impact resistance, flexibility, and recyclability, which make them ideal for demanding applications such as chemical storage tanks, FDA-approved food-safe cutting boards, and durable outdoor recreational equipment.

Their excellent moisture resistance, combined with UV stabilization additives, ensures long-lasting performance even under harsh weather conditions.

Additionally, HDPE’s low coefficient of friction and resistance to mold and rot enhance its suitability for a broad range of projects.

Conversely, PVC sheets provide outstanding chemical resistance and fire-retardant properties, along with a smooth, glossy finish that is visually appealing, making them well-suited for applications like cladding, signage, and medical packaging.

However, PVC tends to be less impact-resistant and more brittle compared to HDPE. Environmental concerns also arise with PVC due to its production process and challenges in disposal and recycling.

Ultimately, the choice between HDPE and PVC plastic sheets depends on the specific requirements of your project.

HDPE is often favored for its durability, sustainability, and ease of fabrication, while PVC may be selected for its aesthetic qualities and fire safety features.

When you purchase HDPE plastic sheets, you can be proud to choose a material that balances performance with environmental responsibility, making it a smart investment for both commercial and DIY projects.

| Feature | HDPE Plastic Sheet | PVC Plastic Sheet |

|---|---|---|

| Impact Resistance | Superior impact resistance | Lower impact resistance |

| Chemical Resistance | Excellent resistance to chemicals, acids, and corrosion | Excellent chemical resistance, particularly in harsh chemical environments |

| Moisture Resistance | Inherently moisture resistant | Highly moisture resistant |

| UV Resistance | Good UV resistance with additives | Good UV resistance with coatings |

| Fire-Retardant Properties | Flammable | Naturally fire-retardant |

| Environmental Impact | More eco-friendly | Higher environmental concerns |

Maintenance And Care Of HDPE Plastic Sheet

HDPE plastic sheets are low-maintenance due to their inherent durability, chemical resistance, and moisture resistance, but proper care ensures optimal longevity and performance.

To maintain HDPE sheets, clean them regularly with mild soap and water using a soft cloth or sponge to remove dirt and stains, avoiding abrasive cleaners that could scratch the surface.

For textured or matte HDPE sheets, a gentle brush can help clean crevices without damaging the finish. Avoid prolonged exposure to extreme heat, as HDPE can soften above 180°F.

For outdoor applications, ensure UV-stabilized sheets are used to prevent degradation, and inspect periodically for wear. Store unused sheets in a cool, dry place away from direct sunlight.

Scratches on smooth or color core HDPE sheets can be minimized with light sanding or buffing, preserving their functionality and appearance.

Conclusion

HDPE plastic sheets offer a versatile, durable, and eco-friendly solution for a wide range of plastic products applications.

With their exceptional high tensile strength, superior impact resistance, and outstanding chemical and moisture resistance, HDPE sheets are engineered to perform reliably in diverse environments and withstand various stresses.

Their resistance to water, mold, and rot further enhances their longevity, making them a dependable choice for both indoor and outdoor projects.

Whether you’re looking to buy material for household items, industrial uses, or commercial displays, HDPE plastic sheets provide a cost-effective, lightweight, and sustainable option.