This article provides a comprehensive guide to understanding the properties, benefits, applications, and processing techniques of Acrylonitrile Butadiene Styrene (ABS) sheets, empowering you to make informed decisions for your projects involving abs plastic sheet materials.

What Is ABS Plastic Sheet?

ABS (Acrylonitrile Butadiene Styrene) is a rigid thermoplastic composed of three key chemicals: acrylonitrile, butadiene, and styrene.

This unique combination gives ABS plastic sheets their renowned high impact resistance, excellent toughness, and moderate heat resistance, with a deflection temperature ranging approximately from 85 to 100°C.

The production of ABS plastic sheets involves an extrusion process where molten polymer is formed into thin, uniform sheets.

This method ensures consistent thickness and quality, making ABS sheets suitable for a wide variety of fabrication techniques including cutting, forming, and gluing.

Due to its versatility, ABS plastic sheet is widely used across various industries, offering an excellent balance of mechanical performance, dimensional stability, and cost-effectiveness.

Sheet Specifications For ABS

ABS (Acrylonitrile Butadiene Styrene) plastic sheets are a versatile and durable material widely used across various industries, and their specifications are key to selecting the right product for specific applications.

ABS sheets are available in a standard size of 1,200mm x 1,000mm x 2,000mm, making them suitable for large-scale projects in construction, automotive, and industrial sectors.

These sheets are manufactured using advanced extrusion techniques, ensuring a consistent, high-impact-resistant structure with a smooth finish, typically available in colors like black.

Benefits Of ABS Sheets

ABS (Acrylonitrile Butadiene Styrene) plastic sheets offer numerous advantages that make them a preferred choice across various industries.

Their high impact strength ensures exceptional durability and reliability in demanding environments, making ABS sheets ideal for applications requiring toughness and resilience.

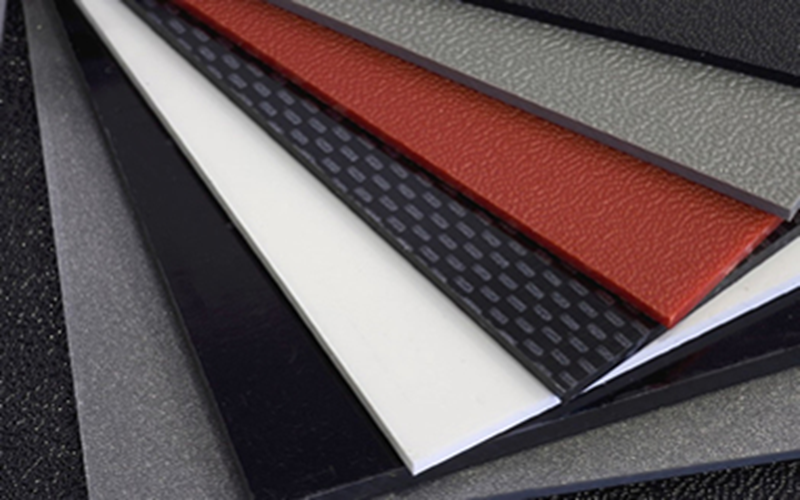

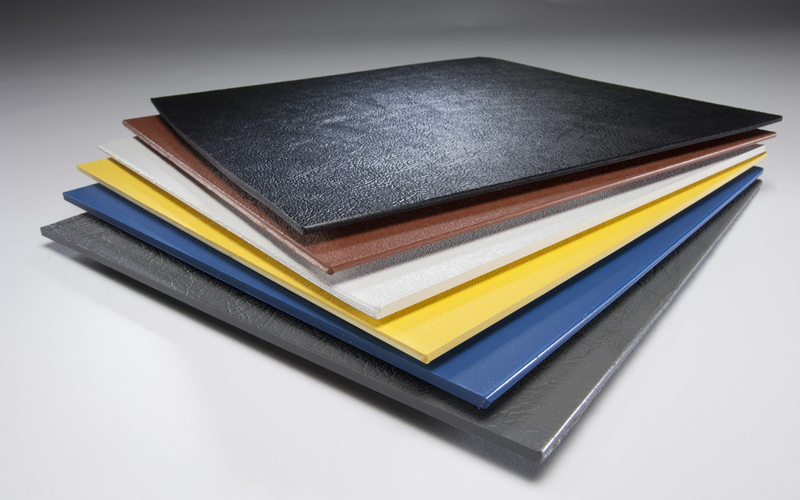

These sheets feature a smooth textured surface on one side, providing aesthetic versatility and a paintable finish that caters to both functional and decorative needs.

Available in various colors, including popular black ABS options, they allow customization to match project specifications.

Cost-effectiveness is another key advantage, offering an economical alternative to other high-performance engineering plastics without compromising quality.

ABS sheets are easy to fabricate, supporting cutting, forming, drilling of holes, and bonding processes, which enhances their adaptability for diverse projects.

Additionally, ABS plastic sheets provide good chemical resistance to alkalis and dilute acids, contributing to their suitability in industrial and consumer applications.

In finally , the dimensional stability of ABS plastic sheets allows them to remain consistent in length and width during processing and use, ensuring precise fit and performance.

What Are ABS Plastic Sheets Used For?

ABS (Acrylonitrile Butadiene Styrene) sheets are widely utilized across various industries due to their durability, versatility, and ease of fabrication.

Automotive

ABS plastic sheets are extensively used in the automotive industry for manufacturing interior components, dashboards, and trim panels.

Their exceptional impact resistance provides durability and safety, while the smooth textured surface allows for easy painting and finishing, enhancing the aesthetic appeal of vehicle interiors.

Additionally, ABS sheets offer excellent dimensional stability and versatility, making them suitable for various automotive applications that require both strength and visual quality.

Consumer Goods

ABS plastic sheets are widely employed in manufacturing consumer goods such as appliance housings, luggage, and toys due to their exceptional toughness, durability, and ease of molding into complex shapes.

Their high impact resistance ensures these products withstand daily wear and tear, while the smooth surface finish allows for easy painting and customization.

This versatility makes ABS sheets ideal for producing reliable and attractive consumer items that meet both functional and aesthetic requirements.

Construction

ABS plastic sheets are widely applied in construction for wall panels, signage, and protective covers. Their durability and cost-effectiveness make them an ideal choice for these applications.

Additionally, ABS sheets offer excellent impact resistance and dimensional stability, ensuring long-lasting performance in both indoor and outdoor environments.

Their smooth textured surface allows for easy painting and customization, enhancing aesthetic appeal while maintaining functional integrity.

Prototyping

ABS plastic sheets are highly popular in prototyping applications, including 3D printing, custom enclosures, and scale models, due to their ease of processing, excellent dimensional stability, and smooth surface finish.

Their ability to be easily cut, formed, and glued makes them ideal for creating precise and durable prototypes, enabling designers and engineers to quickly iterate and validate their designs.

Industrial

ABS plastic sheets are widely utilized in industrial applications such as machine guards, equipment casings, and jigs, where their high impact strength, chemical resistance, and dimensional stability ensure reliable and long-lasting performance.

These sheets withstand harsh environments and mechanical stresses, making them ideal for protecting machinery and enhancing workplace safety.

Additionally, their ease of fabrication allows for custom sizing, drilling of holes, and precise cutting to fit specific industrial requirements, supporting efficient assembly and maintenance processes.

Processing Methods Of ABS Plastic Sheets

Processing ABS plastic sheets is straightforward due to their thermoplastic properties, making them highly adaptable for various fabrication techniques.

Common cutting methods include laser cutting, CNC machining, and sawing, all of which provide precise, clean cuts suitable for intricate designs and accurate dimensions.

These cutting techniques ensure that ABS sheets can be shaped efficiently for both industrial and DIY projects.

Thermoforming and vacuum forming are widely used to shape ABS sheets by heating them until flexible, then molding them into complex or custom shapes.

This versatility allows ABS sheets to be used in applications requiring detailed contours and specific forms, enhancing their suitability for diverse manufacturing needs.

Bonding ABS plastic sheets is effectively achieved through adhesives and solvent welding, which produce strong, durable joints.

These bonding methods ensure the assembled parts maintain high structural integrity and long-lasting performance.

Surface treatments such as painting, coating, and texturing improve both the aesthetic appeal and functional properties of ABS sheets.

Additionally, 3D printing and post-processing techniques are important considerations for prototyping and specialized manufacturing, enabling customization and fine-tuning of ABS components.

Together, these processing methods maximize the performance, appearance, and versatility of ABS plastic sheets across various industries and applications.

ABS Plastic Sheet vs PVC Plastic Sheet

ABS plastic sheets and PVC plastic sheets are both popular thermoplastic materials used in various applications, but they have distinct properties that make them suitable for different uses.

ABS sheets offer superior impact resistance and toughness, making them ideal for applications requiring durability and mechanical strength. They also provide better dimensional stability and heat resistance compared to PVC.

On the other hand, PVC sheets are known for their excellent chemical resistance and flame retardancy, which suits them well for construction and piping applications.

When choosing between ABS and PVC plastic sheets, consider factors such as impact resistance, chemical exposure, temperature requirements, and cost to select the most suitable material for your project.

Selecting The Perfect ABS Plastic Sheet For Your Project

Selecting the perfect ABS (Acrylonitrile Butadiene Styrene) plastic sheet for your project requires careful consideration of several important factors, including thickness, size, color options, and surface texture.

These elements should align with your specific design and functional requirements to ensure optimal performance.

Then, it is essential to assess whether the application will be used indoors or outdoors, as standard ABS has limited UV resistance and may benefit from UV stabilizers or protective coatings to prevent yellowing and degradation when exposed to sunlight.

Additionally, consider the moderate heat resistance of ABS, typically ranging from 85 to 100°C, to ensure suitability for your operating environment.

Balancing cost and performance is key when choosing ABS sheets, as they offer excellent durability and impact resistance at a more affordable price compared to other engineering plastics.

When sourcing ABS plastic sheets, always verify critical material properties such as impact strength, dimensional stability, chemical resistance, and compatibility with your fabrication methods.

Purchasing from reputable suppliers who provide detailed product specifications, clear measurements in inches or millimeters, images, and customer reviews can help you make an informed purchase decision.

Moreover, pay attention to available stock sizes, such as the common 48 x 96 inches sheets, and inquire about custom cutting, hole drilling, or edge finishing services that may be offered to match your project’s dimensions precisely.

During checkout, clarify any special requirements or customization options with the supplier to ensure faster processing and shipment.

Environmental And Sustainability Considerations For ABS Plastic Sheets

When considering the environmental and sustainability aspects of ABS (Acrylonitrile Butadiene Styrene) plastic sheets, their recycling potential is notable but faces challenges due to the material’s non-biodegradable nature and the need for specialized facilities to process mixed plastics effectively.

While ABS plastic sheets can be recycled, the process requires sorting and handling that may not be available in all regions, which can limit their recyclability.

The use of UV stabilizers and additives can enhance ABS’s longevity, particularly for outdoor applications, by mitigating degradation from sunlight exposure, thus extending the material’s lifespan and reducing the frequency of replacement.

For eco-conscious projects, alternatives like PLA or recycled PETG may be considered, as they offer more sustainable profiles with better biodegradability or recycled content.

However, these materials may lack ABS’s durability, impact resistance, and versatility, requiring a careful balance between environmental impact and performance needs.

When selecting ABS plastic sheets, it is also important to consider the shipping and handling processes to minimize environmental footprint, and to note that proper disposal and recycling protocols should be followed to support sustainability efforts.

Overall, while ABS remains a versatile and practical choice, incorporating sustainability considerations into material selection and project planning can help optimize both performance and environmental responsibility.

Summary

In conclusion, ABS plastic sheets stand out as a superior and versatile material suitable for a wide range of applications across various industries.

Their exceptional high impact resistance, excellent dimensional stability, and ease of fabrication—including cutting, drilling, gluing, and forming—make them a preferred choice for both industrial and consumer projects.

Additionally, ABS sheets offer cost-effectiveness without compromising quality, along with good chemical resistance and a smooth textured surface that supports painting and finishing.

By understanding their unique properties, numerous benefits, and versatile processing methods, you can confidently select and optimize the use of ABS plastic sheets for successful, durable, and aesthetically pleasing projects.