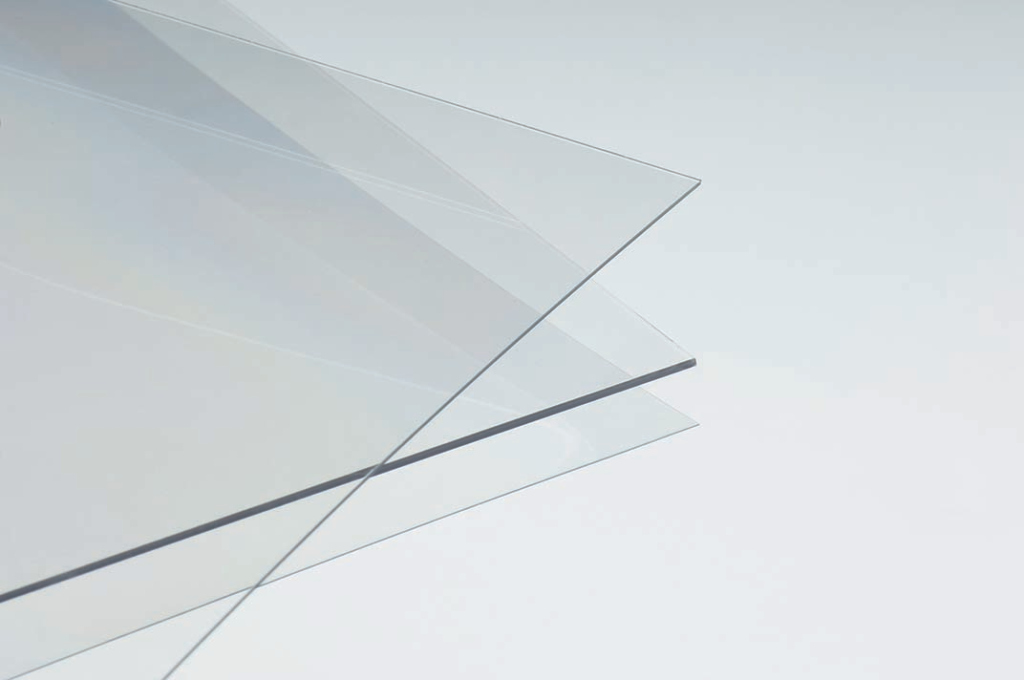

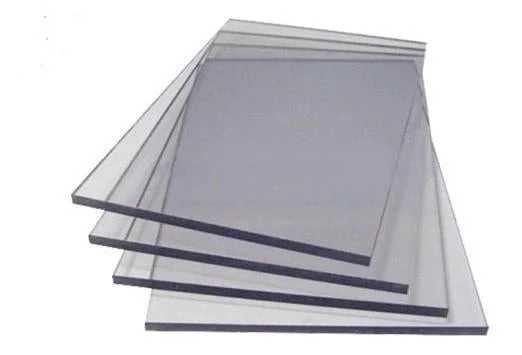

PETG (Polyethylene Terephthalate Glycol) sheets are durable, clear, and easy to use thermoplastic polyester materials widely favored for their excellent impact resistance, chemical resistance, and versatility.

They excel in applications such as 3D printing, packaging, signage, and protective covers due to their ability to be easily fabricated through cutting, heat bending, and complex die cuts without sacrificing structural integrity.

This article covers their key features, benefits, common uses, and practical tips on how to work with PETG sheets effectively, helping you understand why they remain a top choice in various industries.

What Is Polyethylene Terephthalate Glycol (PETG) Sheet?

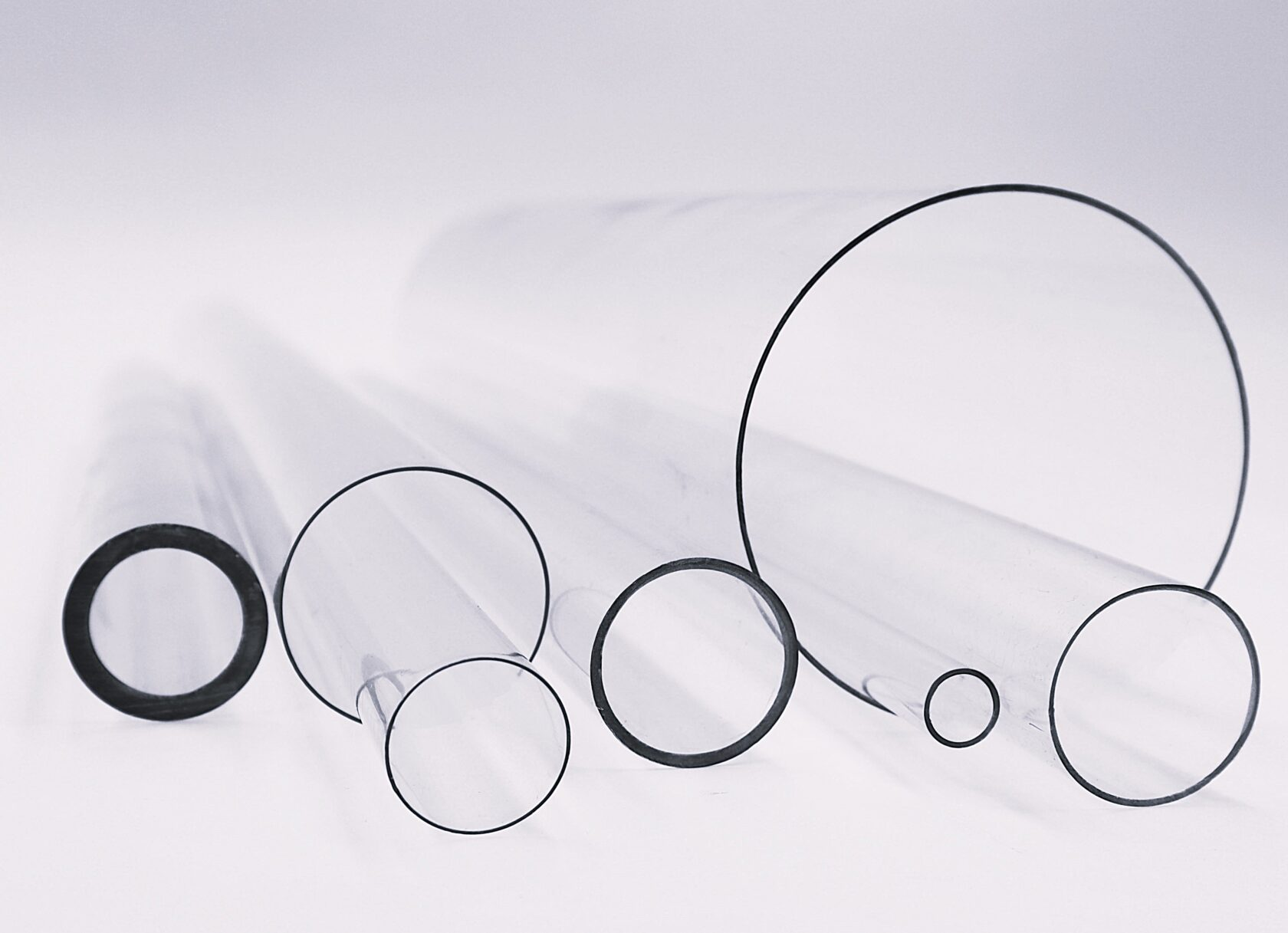

A PETG Plastic sheet, made from Polyethylene Terephthalate Glycol, is a versatile thermoplastic known for its clarity, durability, and flexibility.

Unlike standard PET, PETG is modified with glycol to enhance its impact resistance and ease of fabrication, making it ideal for applications like 3D printing, packaging, and signage.

It offers a balance of strength, chemical resistance, and recyclability, distinguishing it from other plastics like acrylic or polycarbonate.

Benefits Of PETG Plastic Sheets

PETG Plastic sheets offer a wide range of benefits, making them a preferred material across many industries. Their outstanding impact resistance and toughness provide exceptional durability, allowing them to withstand heavy use, impacts, and stress without cracking or breaking.

Thanks to their low forming temperature, PETG sheets are easy to fabricate using various methods such as die cutting, heat bending, and thermoforming.

This allows for designs that require deep draws and intricate shapes without sacrificing structural integrity, supporting creative and functional applications in packaging, signage, and pop displays.

In addition to their mechanical strengths, PETG sheets boast excellent optical clarity and aesthetic appeal, delivering a professional, crystal-clear finish ideal for retail and display purposes.

They are also FDA compliant and food-safe, making them suitable for direct food contact and medical applications.

Moreover, PETG’s chemical resistance and UV stability ensure reliable performance in both indoor and outdoor environments, resisting degradation from exposure to sunlight and various chemicals.

PETG sheets are recyclable, contributing to sustainable manufacturing practices.

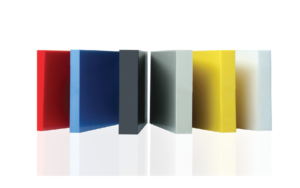

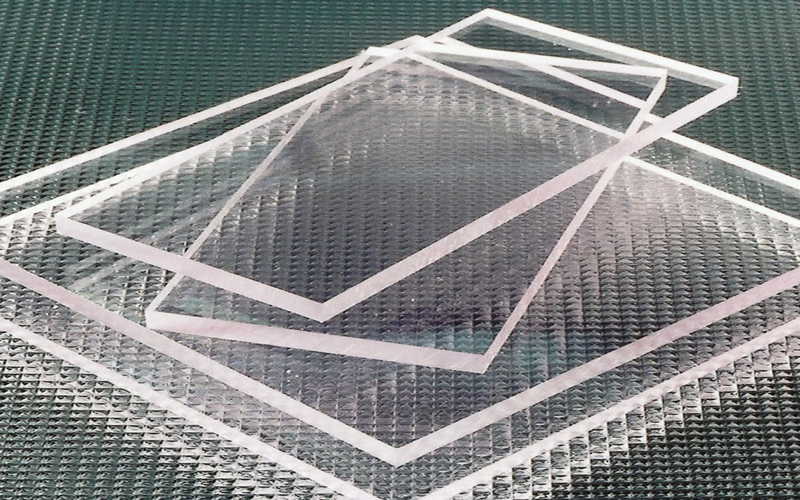

Available in a variety of thicknesses and sizes, PETG sheets can be easily purchased and shipped, with many suppliers offering options to add to cart and customize orders, making them accessible and convenient for both industrial users and DIY enthusiasts.

What Are PETG Sheets Used For?

PETG sheets are widely used across diverse applications due to their exceptional versatility, durability, and robust properties.

3D Printing

In 3D printing, PETG serves both as filament and sheet material, prized for its ease of use, strong adhesion, and flexible yet sturdy output, making it ideal for prototyping and functional parts.

Packaging

In packaging, PETG sheets are favored for food containers, blister packs, and protective packaging, offering outstanding clarity, chemical resistance, and FDA compliant food-safe properties.

Signage And Displays

For signage and retail displays, PETG’s crystal-clear transparency and aesthetic appeal make it a top choice for eye-catching POP displays and store fixtures that require complex die cuts and deep draws without sacrificing structural integrity.

Many suppliers make it easy to purchase these sheets online, allowing customers to simply cart add the desired sizes and quantities for quick checkout.

Medical

In the medical field, PETG is widely used for protective shields, device components, and orthotic and prosthetic devices, leveraging its durability, impact resistance, and chemical stability.

Industrial

Industrially, PETG sheets are employed as machine guards, protective covers, and safety barriers, providing reliable impact resistance and toughness in demanding environments.

Thanks to its low forming temperature, PETG plastic sheets can be easily heat bent, die cut, and fabricated to meet custom project requirements, making them a preferred material for both commercial and DIY applications.

Overall, PETG sheets combine durability, clarity, and ease of fabrication, making them indispensable across a broad range of industries and uses.

Processing Methods Of PETG Plastic Sheets

Working with PETG sheets is straightforward due to their versatility and user-friendly properties, but applying proper techniques ensures optimal results and maintains the material’s durability and clarity.

Cutting PETG sheets can be efficiently achieved using laser cutters for precision, CNC machines for complex shapes, or manual tools like fine-toothed saws and scoring knives for simpler tasks, always ensuring clean edges without cracking.

Thermoforming and bending processes benefit from PETG’s low forming temperature, allowing easy shaping using heat guns, ovens, or specialized thermoforming equipment. This enables designs that require deep draws and complex die cuts without sacrificing structural integrity.

For bonding PETG sheets, use compatible adhesives such as solvent-based cements, UV-curable glues, or specialized plastic welds to create strong, durable joints. Avoid using incompatible glues that may cause clouding or weakening of the material.

To maintain the clarity and longevity of PETG sheets, clean them regularly with mild soap and water, avoiding abrasive materials or harsh chemicals that could scratch or degrade the surface. Use soft cloths or sponges for cleaning.

Safety precautions during fabrication are essential: always wear protective gear like gloves and safety goggles, ensure proper ventilation when heating or gluing, and follow tool-specific safety guidelines to prevent injury and material damage.

By following these best practices, you can effectively fabricate, form, and assemble PETG plastic sheets for a wide range of applications, ensuring professional-quality results and maximizing the material’s performance.

PETG Sheets vs Acrylic Sheets

When comparing PETG sheets with acrylic sheets, each material offers distinct advantages depending on the project.

PETG sheets excel in impact resistance and flexibility, making them highly impact resistant and less likely to crack under stress, which is ideal for applications like 3D printing or protective covers.

Acrylic sheets, however, are known for their superior scratch resistance and optical clarity, often preferred for displays or signage where surface durability is key.

PETG is easier to fabricate, requiring less heat for thermoforming, and is often more affordable, making it a popular choice to shop for when durability and ease of use are priorities.

Before purchasing, it’s wise to review customer feedback and product specifications to ensure the PETG sheets meet your specific needs.

Choosing between the two depends on whether durability and ease of use (PETG) or scratch resistance and clarity (acrylic) are prioritized.

Selecting The Perfect PETG Sheets For Your Project

Choosing the right PETG sheets requires careful consideration of several key factors to ensure they meet your project needs.

Start by assessing project requirements, such as the desired size, thickness, and clarity, to match the sheet’s properties to your application, whether for signage or prototyping.

Next, evaluate environmental factors like UV exposure, chemical contact, or outdoor use, as PETG’s UV and chemical resistance make it suitable for harsh conditions.

Consider fabrication methods, ensuring the sheets are compatible with your planned cutting, thermoforming, or 3D printing processes for seamless production.

Additionally, check certifications to confirm the PETG meets food-safe or medical-grade standards if required for packaging or medical applications.

Finally, balance budget and sourcing by comparing quality, cost, and reputable suppliers to secure reliable, high-quality PETG sheets that fit your project’s scope and constraints.

Summary

PETG sheets are versatile and valuable materials that offer numerous benefits across various industries. From their high impact resistance and ease of fabrication to their transparency and food-safe properties, PETG sheets are a preferred choice for many applications.

They excel in 3D printing, packaging, signage, medical, and industrial uses, providing solutions that are both functional and aesthetically pleasing.

Working with PETG sheets is straightforward, thanks to their flexibility and low forming temperature.

Whether you’re cutting, thermoforming, or gluing, PETG sheets can be manipulated to meet specific requirements without compromising on quality.

Comparing PETG sheets with other plastics highlights their unique advantages, making them a cost-effective and durable option.

We hope this article has provided you with a comprehensive understanding of PETG sheets and inspired you to explore their potential in your projects.