In a world where design and functionality converge, coloured acrylic sheets have emerged as a vibrant and versatile solution for creators, architects, and businesses alike.

Known for their striking aesthetics, durability, and ease of use, these sheets—crafted from high-quality PMMA—offer a spectrum of colours and finishes to transform any project.

From illuminating retail displays to crafting bespoke furniture or bold art installations, coloured acrylic sheets unlock endless possibilities.

This article delves into their unique features, diverse applications, and why they are the material of choice for innovative designs across industries.

What Is Colored Acrylic Sheet?

Colored acrylic sheets are versatile plastic sheets made from polymethyl methacrylate (PMMA) infused with various pigments to produce a wide range of vibrant colors.

These sheets combine the clarity and durability of acrylic with the aesthetic appeal of rich hues, making them ideal for numerous applications such as signage, furniture, lighting, and decorative projects.

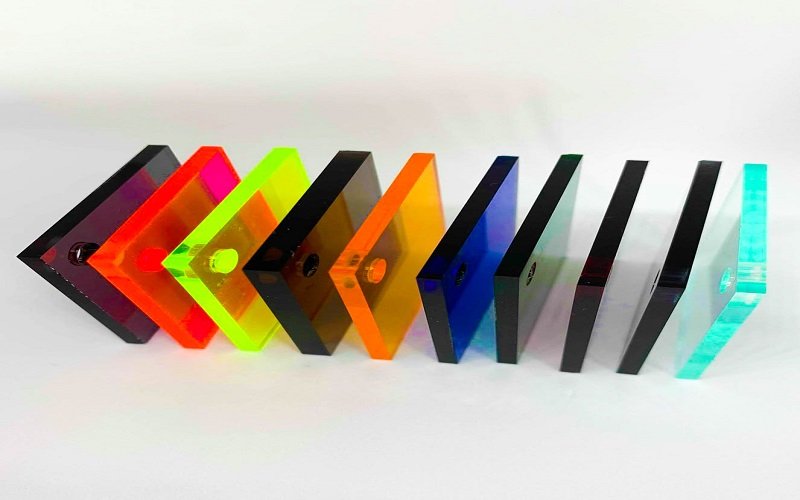

Available in different thicknesses and finishes—including matte, polished, and textured surfaces—they offer excellent weather resistance, UV stability, and impact strength, often outperforming traditional glass in both performance and safety.

Key Features Of Coloured Acrylic Sheets

Coloured acrylic sheets, made from high-quality PMMA, are prized for their versatility and performance across various applications. Below are their standout features::

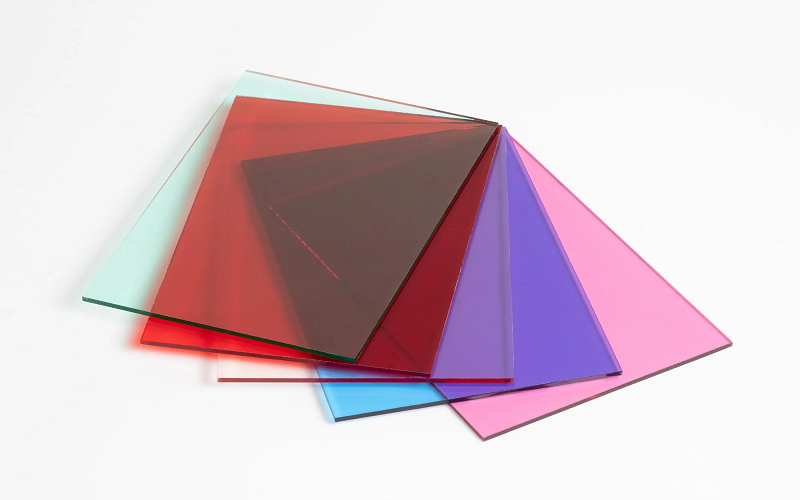

Excellent Transparency and Weather Resistance: Coloured acrylic sheets have a light transmittance of over 92%, offering transparency close to that of glass, but they are lighter and more impact-resistant. Additionally, they possess good UV resistance and weather durability, making them suitable for long-term use without easily fading.

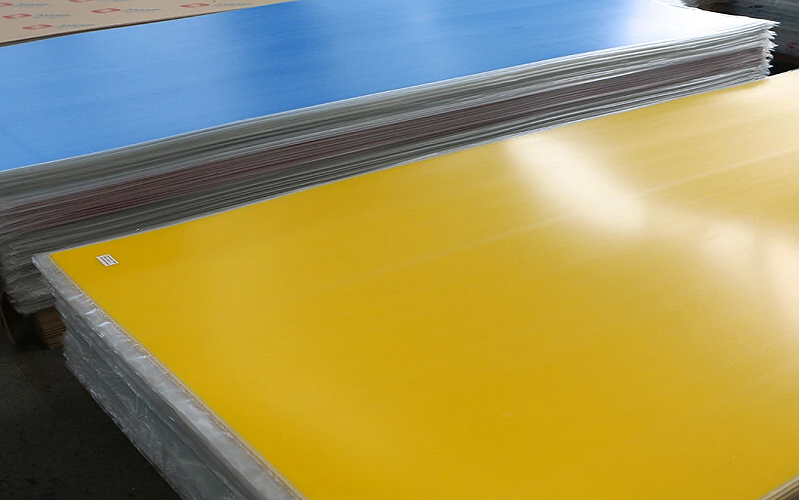

Wide Range of Colour Options: Coloured acrylic sheets are available in a variety of colours, including solid colours such as clear, red,pink,black,gray, blue, green,bronze ,yellow, purple, and orange, as well as gradient colours, pearl colours, metallic colours, and finishes like matte, glossy, and mirror surfaces. This rich palette and range of effects can meet diverse design requirements.

Good Processability: Coloured acrylic sheets are easy to process, cut, engrave, drill, bend, and bond, making them suitable for creating various shapes and designs to meet custom needs. Moreover, they have good thermoplasticity and mechanical processing properties, allowing for thermoforming and machining operations.

How To Make Colored Acrylic Sheets?

The manufacturing process of coloured acrylic sheets typically involves three main stages: raw material preparation, forming processing, and surface treatment.

1. Raw Material Preparation

Raw Material Dyeing: Pigments or dyes are added to polymethyl methacrylate (PMMA) raw materials for coloring. These dyes must have high weather resistance, chemical corrosion resistance, and excellent color rendering.

Mixing and Polymerization: The dye is mixed with monomers through suspension polymerization or bulk polymerization to form a resin system with uniform color.

2. Processing

Cast Acrylic

The molten resin is poured into molds and cooled to solidify, suitable for producing sheets or profiles with high transparency and dimensional stability. For example, cast acrylic sheets undergo post-processing by holding at 60°C and 120°C for two hours each.

Extrusion Acrylic

The molten resin is extruded through a high-temperature extruder to form shapes such as tubes and profiles. Although extruded acrylic sheets have slightly lower transparency than cast sheets, their production efficiency is higher and cost is lower.

3. Surface Treatment Stage

Spraying or Printing: For products requiring special colors or patterns, spraying or screen printing techniques are used. For example, lightbox advertising boards often use spraying to enhance color layering.

Thermoforming and Polishing: The sheets are softened by heating and bent into shape, then surface gloss is improved by mechanical or chemical polishing.

Applications Of Coloured Acrylic Sheets

Coloured acrylic sheets are widely used across various industries due to their versatility, vibrant colours, and durability. Here are some of the most popular applications:

Retail and POP Displays: These sheets are ideal for creating eye-catching point-of-purchase (POP) displays that attract customers and enhance product visibility. Their bright colours and polished finishes make them perfect for showcasing merchandise in stores.

DIY Projects and Crafting: Hobbyists and designers often use coloured acrylic sheets for DIY projects, including custom decorations, art pieces, and personalized gifts. The sheets are easy to cut, shape, and bond, allowing for creative freedom.

Signage and Advertising: Thanks to their excellent weather resistance and clarity, coloured acrylic sheets are frequently used for outdoor and indoor signage. They can be laser cut and engraved to produce detailed logos, letters, and graphics.

Furniture and Interior Design: Designers incorporate coloured acrylic sheets into furniture and interior elements to add a modern, vibrant touch. The sheets can be used for cabinet doors, wall panels, and decorative accents.

Lighting Fixtures: Their high light transmittance and colour options make these sheets suitable for lighting applications such as lamp covers, lightboxes, and diffusers, enhancing ambiance with vivid hues.

Protective Barriers and Covers: Coloured acrylic sheets also serve functional roles as protective barriers, machine guards, or covers, combining safety with aesthetic appeal.

With a wide selection of sizes, thicknesses, and finishes, coloured acrylic sheets provide an ideal material choice for projects that require both functionality and style.

Benefits Of Coloured Acrylic Sheets

Coloured acrylic sheets offer a range of advantages that make them a preferred material for designers, architects, businesses, and DIY enthusiasts. Below are the key benefits:

Cost-Effective Alternative: Compared to glass or metal, acrylic sheets are more affordable while delivering similar aesthetic and functional qualities, reducing project costs without compromising quality.

Highly Customizable: Available in a variety of colours, finishes (transparent, translucent, opaque, glitter, mirrored), and thicknesses (0.5mm to 50mm), they can be tailored to meet specific design or branding requirements, with options for laser cutting, engraving, or printing.

Enhanced Safety: Shatter-resistant and up to 17 times stronger than glass, acrylic sheets minimize the risk of injury, making them ideal for public spaces, schools, or homes.

Lightweight Design: Weighing half as much as glass, they are easier to handle, transport, and install, reducing labor costs and structural support needs.

Low Maintenance: The non-porous surface resists stains, dirt, and bacteria, requiring only simple cleaning with mild soap and water to maintain a pristine look.

These benefits position coloured acrylic sheets as a practical, stylish, and durable solution, empowering users to achieve innovative designs with ease and efficiency across various projects.

Coloured Acrylic Sheets Laser Cutting Service

MUDUSA Acrylic offers a premier laser cutting service for coloured acrylic sheets, delivering precision-crafted solutions for your creative and industrial projects.

Using state-of-the-art CO2 laser technology, we cut high-quality PMMA (Polymethyl Methacrylate) sheets, known as Perspex or Plexiglass, into custom shapes and sizes with exceptional accuracy and polished edges.

Our service accommodates a wide range of vibrant colours, finishes (transparent, translucent, opaque, glitter, and mirrored), and thicknesses from 0.5mm to 12mm.

Whether you need intricate designs for signage, retail displays, jewelry, or architectural features, we ensure clean cuts with minimal waste and no post-processing required. Simply provide a vector CAD file, or let us convert your paper templates into digital designs.

With fast turnaround times, U.S.-wide shipping, and competitive pricing, MUDUSA Acrylic is your trusted acrylic sheet manufacturer for transforming visions into reality. Contact us today for a tailored request quote or to discuss your project requirements.

Conclusion

Coloured acrylic sheets, made from high-quality PMMA, are a versatile material ideal for design, architecture, and creative projects due to their vibrant aesthetics, durability, and ease of processing.

They offer a range of colours and finishes (transparent, translucent, opaque, glitter, mirrored), high impact resistance (up to 17 times stronger than glass), lightweight construction, UV and weather resistance, and easy fabrication through laser cutting or molding.With low-maintenance, non-porous surfaces and recyclable options, they are eco-friendly.

Companies like MUDUSA Acrylic provide precise laser cutting services to meet diverse needs, such as retail displays or architectural features, making these sheets a dynamic solution for innovative and practical projects.